Understanding the Difference Between Takt Time and Cycle Time

You might wonder about the difference between takt time and cycle time. Takt time shows how fast you need to make products to keep up with customer demand, while cycle time measures how long it actually takes to make one item. When you track both, you spot problems and find ways to work better.

You can see if your production matches what customers want.

You notice delays or bottlenecks.

You find areas for improvement and make your workflow smoother.

Companies that focus on takt time cycle time metrics often reach higher productivity and stay ahead in their industry.

Takt Time

Takt Time Definition

Takt time sets the pace for making things. You use takt time to match how fast you work with what customers want. In lean manufacturing, takt time means the most time you can spend on one product before starting another. This keeps your work in line with customer needs.

Takt time is like the heartbeat of your factory. It helps you not make too many or too few items. You can check if your team is keeping up with orders and find problems early.

Takt time is found by dividing the time you have by what customers want.

It shows how fast you need to work to meet demand in a set time.

Takt time tells you the most time you can take between finishing one item and starting the next.

Takt Time Calculation

You can figure out takt time with a simple math formula. Many experts use this way:

Source | |

|---|---|

Mingosmartfactory | Production time available / required units of production |

Master-assembly | Available Working Time / Demand |

6sigma.us | Available Working Time / Required Output |

Inboundlogistics | Available Production Time / Customer Demand |

Azumuta | Available production time / Customer demand |

For example, if you have 480 minutes to work in a day and customers want 240 items, you find takt time like this:

Takt Time = 480 minutes / 240 units = 2 minutes per unit

This means you should finish one item every 2 minutes to keep up.

Takt Time Benefits

You get many good things when you use takt time in your factory. Here are some main benefits:

Better planning: You can set up work to match what customers want.

More efficiency: You find and remove waste in your work.

Happier customers: You deliver orders on time and keep people happy.

Lower costs: You cut waste, so you spend less money.

Better quality: You make tasks the same way, so you make fewer mistakes.

Takt time helps you match your work with what customers want. You keep wait times short and make customers happier. When you focus on takt time cycle time, you see why takt time matters in lean manufacturing. You also learn the difference between takt time and cycle time and how both help you work better.

Cycle Time

Cycle Time Definition

Cycle time tells you how long it takes to finish one product. It starts when you begin and ends when you are done. In factories, cycle time means the total time for one job or batch. People use cycle time to check how well their work is going. You can look at the usual cycle time, which is the average time. You can also look at the ideal cycle time, which is the fastest possible time.

Cycle time counts every step, from the first to the last. It even includes waiting times. For example, making a chair means cutting wood and waiting for glue to dry. Cycle time adds up all these steps. This shows your real production speed.

Cycle time helps you find slow spots.

Shorter cycle times mean you make things faster.

You can use cycle time to compare with takt time. This helps you see if you are meeting what customers want.

Cycle Time Calculation

You can figure out cycle time with a simple math formula. The usual way is to divide the total work time by the number of items made. Here is a table that shows how to do it:

Cycle Time Formula | Description |

|---|---|

cycle time | net production time / number of units produced |

To get cycle time, count how many things you make and how long it takes. For example, if you make 2000 items in 20 hours, you do this:

Cycle Time = 20 hours / 2000 units = 0.01 hours per unit (or 0.6 minutes per unit)

You use this number to check if you are working fast enough. Cycle time shows your real speed. It helps you find ways to make your work better.

Cycle Time Benefits

Watching cycle time gives you many good things in your factory. You can see these in the table below:

Benefit | Description |

|---|---|

Operational Efficiency | You cut down on delays and make your service better by checking cycle time. |

Resource Optimization | You use your tools and people better and match what you make to what people want. |

Improved Service Quality | You meet what customers expect more often and deliver on time. |

You get a clear look at how your work goes. You can make changes to help your team work better. The good things about cycle time are better planning, faster work, and happier customers. When you watch both takt time and cycle time, you make your work smoother and stay ahead in your field.

Takt Time vs. Cycle Time

Key Differences

It is important to know how takt time and cycle time work. Both help you make your factory better, but they do different things. Takt time sets the speed for your team. It tells you how quickly you should make each product to match what customers want. Cycle time shows how long it really takes to finish one item from start to end. When you look at both, you can see if your work matches what people need.

Here is a table that shows the main ways takt time and cycle time are not the same:

Aspect | Takt Time | Cycle Time |

|---|---|---|

Definition | Time needed to produce a product to meet demand | Time taken to complete the production of a unit |

Calculation | Available production time / Customer demand | Total production time / Number of units produced |

Example | 450 minutes / 150 units = 3 minutes per unit | 80 minutes / 20 units = 4 minutes per unit |

Takt time gives your team a goal to reach. Cycle time lets you see how fast you really work. If your cycle time is more than your takt time, you might have slow spots or delays. If your cycle time is less, you could make too many things and waste stuff.

You use takt time to keep your work matching what customers want. You use cycle time to check how well your team does the job. Both help you find slow spots and fix problems in your factory.

Why the Difference Matters

Knowing how takt time and cycle time are different helps you run your factory better. Takt time keeps your work matching what customers want. You do not make too many or too few things. Cycle time shows your real speed. You can find slow steps and fix them.

Here is a table that shows how each idea helps in a different way:

Concept | Purpose | Key Points |

|---|---|---|

Takt Time | Aligns production speed with customer demand | - Helps identify inefficiencies and bottlenecks. |

- Encourages lean production by reducing overproduction. | ||

Cycle Time | Focuses on the efficiency of the production process | - Highlights process efficiency. |

- Reflects the real-world capacity of your production system. |

At Toyota, workers use takt time to guide their work. They can see right away if they are behind or ahead. This helps them fix problems fast and keep things running smoothly.

If you mix up takt time and cycle time, you can have problems in your factory. You might see slow spots in your work. You could have waste or not use your tools well. You might make too much or too little. Delays can stop you from giving customers what they want. Customers may not be happy if you are late. You may also waste things if you have too much extra.

Takt time cycle time numbers help you find problems early.

You can make your factory better by watching both numbers.

You keep your work going well and make customers happy.

When you pay attention to takt time and cycle time, you make better choices in your factory. You keep your team working at the right speed. You send out products on time and do not waste things. You build a strong way to match your work with what customers want.

Using Takt Time and Cycle Time

Practical Use Cases

You can use takt time and cycle time in many jobs. These ideas help factories and service places work better. When you figure out takt time, you set a clear pace for your team. For example, a furniture factory may need to make 50 pieces each day. Workers finish one piece every 480 seconds. A juice company might fill 600 bottles daily. The team finishes one bottle every 50 seconds. These goals help you keep up with what people want. They also stop you from making too much.

Takt time is important in lean manufacturing. It matches how fast you work with what customers want. You can watch your output and spot problems quickly. Cycle time shows how long it takes to finish one item. If cycle time is longer than takt time, you are behind. If cycle time is shorter, you might make too much.

Here are some ways you can use these numbers:

Track last cycle time to set the best cycle time.

Use Short Interval Control to fix cycle time loss fast.

Show ideal and last cycle times during changeovers.

Alert workers when things run slower than the best cycle time.

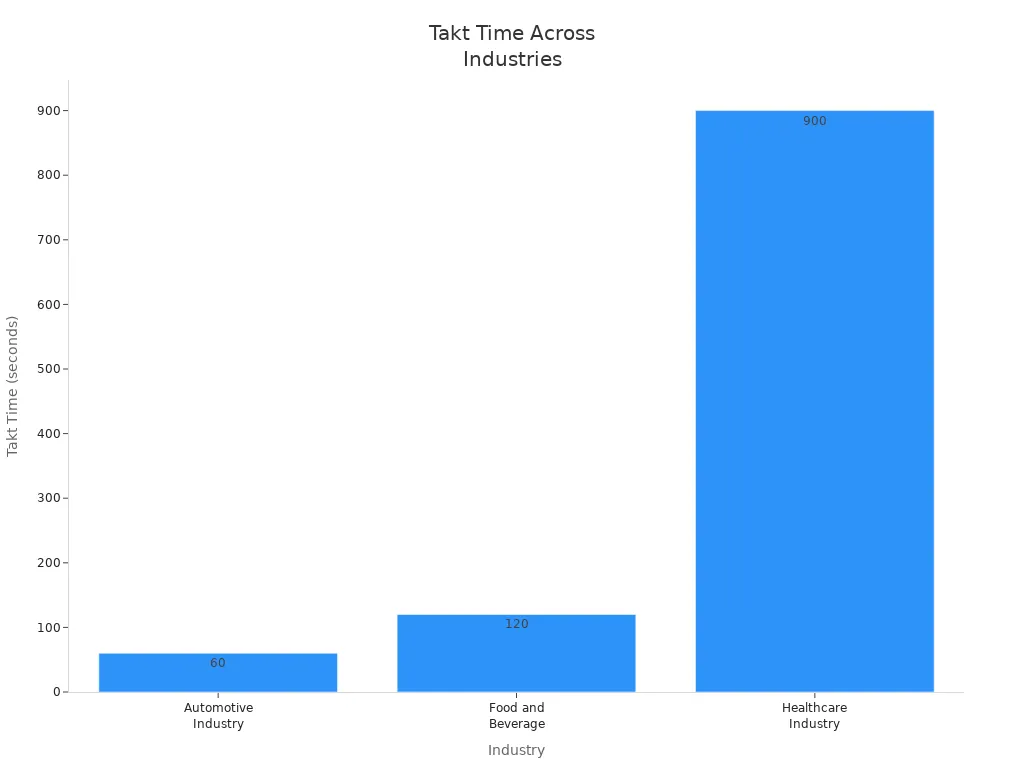

You can see how different jobs use takt time in this table:

Industry | Example of Takt Time Application | Takt Time Interval |

|---|---|---|

Automotive Industry | At Toyota's Georgetown plant, each worker completes a task every 60 seconds to keep things moving. | 60 seconds |

Food and Beverage | A coffee shop makes and serves drinks every 2 minutes to stay steady during busy times. | 2 minutes |

Healthcare Industry | A doctor's office sets appointments every 15 minutes for a steady flow. | 15 minutes |

Service Industry | A call center answers calls within a set time to help customers quickly. | N/A |

Common Mistakes

You may have problems if you do not use takt time and cycle time the right way. Many people do not understand takt time and use it for jobs that are not repeated. This causes problems. Some pick big machines instead of simple ones. This slows down work. Others use takt time for hiring, but it should match work with demand.

Cycle time mistakes happen when you mix it up with lead time. If you only use people to do work, cycle time can get longer because of mistakes and tiredness. Bad care of machines can make them break, which makes cycle time longer. Bottlenecks also slow down your work.

You can avoid these problems by doing these things:

Draw spaghetti diagrams to find movement problems.

Move workstations for easier access.

Find delays using root cause analysis.

Fix bottlenecks to speed up work.

Use just-in-time inventory to cut waiting.

Train your team to do more jobs.

Add more workers to share the work.

Automate jobs that repeat for faster results.

Use robots to help workers.

Use automated checks for quick quality control.

Use lean manufacturing to remove waste.

Get your team to help solve problems.

When you use takt time and cycle time together, you can make your work smoother and meet what customers want.

You have learned that takt time tells you how fast you need to work to meet what customers want. Cycle time shows how long it really takes to make each thing.

Aspect | Takt Time | Cycle Time |

|---|---|---|

Focus | Customer demand | Internal efficiency |

Role | Sets production target | Measures actual performance |

If you use both numbers, you can find slow spots. You can make work fair for everyone and make things better.

You waste less and get more done.

You deliver on time and keep customers happy.

Try these ideas in your daily work. You will notice things run better and results improve as time goes on.

FAQ

What happens if your cycle time is longer than your takt time?

You may fall behind on orders. This means you cannot keep up with customer demand. You should look for slow steps and fix them to speed up your process.

Can you use takt time in service jobs?

Yes! You can set a pace for tasks like answering calls or serving food. Takt time helps you match your work speed with what customers expect.

How do you track cycle time in a busy factory?

Use a stopwatch or timer for each step.

Write down start and finish times.

Review your notes to find delays.

Is takt time always the same every day?

Day | Takt Time Changes? |

|---|---|

Busy Days | Yes |

Slow Days | Yes |

Holidays | Yes |

Takt time changes when customer demand or available work time changes. You should check it often.

See Also

A Simple Explanation of Total Productive Maintenance Concepts

An Overview of Taper and Angle Inspection Fundamentals

Exploring Various Types of CNC Cutting Tools Available

The Meaning of TIMWOOD in Lean Manufacturing Practices

A Clear Guide to Measurement System Analysis for Quality

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.