Subtractive Manufacturing Explained Simply for Everyone

Imagine you have a block of wood, and you want to turn it into a toy car. You remove parts you do not need by cutting or shaping. This is what subtractive manufacturing means. You start with a solid piece and take away material until you create the final shape. This process helps you make many products you see every day in manufacturing.

Subtractive Manufacturing Basics

Definition

Subtractive manufacturing shapes things by removing what is not needed. You begin with a solid block called a blank or workpiece. Tools help take away material until you get the shape you want. This method is similar to sculpting. You chip away at the block, and the finished part appears as you remove extra material.

Many industries use subtractive manufacturing for parts with exact shapes and sizes. Factories use machines to cut, drill, or grind metal blocks. Techniques like cnc milling, cnc drilling, and cnc laser cutting make parts with precise measurements. Computers control these machines, so results are always the same.

Subtractive manufacturing works with materials that must be strong and dependable. Here are some common materials:

Steel: Used for building frames and making tools.

Titanium: Very strong and light, needed for aerospace.

You can check this table to see how materials are used in subtractive manufacturing:

Material | Common Grades | Applications |

|---|---|---|

Aluminum | 7075-T6, 7075, 2024 | Aerospace parts, automotive parts |

Titanium | Grade 2, Grade 5, Grade 23 | Landing gears, medical implants |

Inconel | 718, 625, 738 | Turbine disks, oil & gas tools |

Steel | Mild steel, stainless steel, tool steels | Frames, food equipment, molds, cutting tools |

You find these materials in things like cars and kitchen tools. Cnc machines shape them with high accuracy.

Why “Subtractive”

It is called subtractive manufacturing because you remove material from the block. The name comes from how you make the final product. You do not add anything; you only take away what you do not need. This is different from additive manufacturing, where you build up layers to make a part.

Tip: Subtractive manufacturing usually makes more waste than additive methods. You cut away extra material, so there are leftover scraps.

The word "subtractive" became popular when new technologies like 3D printing appeared. People needed a way to talk about older methods that remove material. Now, "subtractive manufacturing" means traditional machining, especially when compared to newer ways.

Cnc machines are important in subtractive manufacturing. You use cnc milling to carve shapes, cnc turning to spin and cut parts, and cnc drilling to make holes. Each cnc method removes material in a controlled way. You get smooth surfaces and sharp edges, which are needed for many products.

Subtractive manufacturing is all about shaping by taking away. You start with extra material and finish with just the right part.

Subtractive Manufacturing Process

Step-by-Step

When you use subtractive manufacturing, you follow clear steps. You start with a plan and end with a finished part. Here is how you turn an idea into something real:

Design Your Part

You make a 3D model or drawing using CAD software. This plan shows what your part will look like.Choose the Raw Material

You pick the best material for your project. It could be plastic, metal, or wood.Prepare the CNC Program

You use CAM software to make instructions for the cnc machine. The program, called G-code, tells the machine what to do.Set Up the Machine

You put the raw material in the cnc machine. You make sure it is tight and ready to cut.Start the Machining Process

The cnc machine uses tools to take away material. It follows your program to shape the part.Check Quality

You measure and look at the part while you work. You check if it matches your plan.Finish the Part

You clean, polish, or treat the part. This gives it the right look and feel.

Tip: Always stay safe when using machines. Wear gloves and goggles. Keep your area clean. Know what to do if something goes wrong.

From Raw Material to Part

You use different ways to shape your part. Each way removes material in its own style. Here are the most common methods:

Technique | Description | Applications |

|---|---|---|

Cutting | Takes away material with a cutting tool. | Used to make many parts and tools. |

Drilling | Makes holes with a spinning drill bit. | Used for screw holes and decorations. |

Grinding | Uses a spinning wheel to smooth surfaces. | Used for finishing and careful work. |

Boring | Makes holes bigger with a special tool. | Used in engines and turbines. |

You often use cnc machines for these jobs. For example, cnc cutting shapes the outside of a part. Cnc drilling makes holes. Cnc grinding smooths surfaces. Cnc boring changes hole sizes. Each way helps you get the shape and finish you want.

Note: Safety is very important in subtractive manufacturing. You must protect yourself from sharp tools and loud sounds. Here are some common safety rules:

Safety Protocols | Description |

|---|---|

Personal Protective Equipment | Gear like gloves and goggles to keep you safe. |

Ventilation | Systems that move air and keep fumes away. |

Fire Prevention | Ways to stop fires, like storing things safely. |

Waste Management | Steps to throw away dangerous waste safely. |

Training | Teaching workers about safety and emergencies. |

Subtractive manufacturing needs good planning, strong machines, and safe habits. If you follow each step, you can turn a block into a useful part.

Methods and Machines

CNC Machining

Cnc machines are used a lot in subtractive manufacturing. These machines use computers to control tools very accurately. You can shape metal, plastic, or wood with cnc machines. The process starts with a digital plan. The cnc machine follows this plan and removes material step by step. You can make parts for things like integrated circuits, airplane parts, or car engines.

Cnc machining lets you make very small and smooth details. This is important for industries like aerospace, cars, and medical devices. These machines help avoid human mistakes and make every part the same. You save time and make less waste.

Tip: Cnc machines work quickly and do the same job over and over. This means you get the same good results every time.

Industry | Precision Requirement |

|---|---|

Aerospace | High precision within thousandths of an inch |

Automotive | Complex and intricate components |

Medical Devices | Essential for quality and reliability |

Milling and Turning

Cnc milling and cnc turning are two main ways to shape parts. In cnc milling, the tool spins and moves in different directions. The part you are working on does not move. Milling is good for making shapes, holes, and curves. Cnc turning works in another way. The part spins while the tool moves along its outside. Turning is best for round or tube-shaped parts.

Aspect | CNC Milling | CNC Turning |

|---|---|---|

Movement | Rotating tools move; workpiece is fixed | Workpiece rotates; tool moves on surface |

Machine Design | Multi-axis system for complex cuts | Two axes for cylindrical parts |

Tooling Strategies | Rotating cutters shape from many angles | Stationary tool shapes rotating workpiece |

Geometric Capability | Best for complex shapes | Best for round, symmetrical parts |

Surface Finish | May need extra finishing | Produces smooth surfaces |

Production Efficiency | Good for low-to-medium volume | Fast and cost-effective for round parts |

You use cnc machines for both milling and turning. Each way lets you control the shape and how smooth the part is. You can make things like car wheels or medical parts.

Other Techniques

There are more ways to shape parts in subtractive manufacturing. Electrical Discharge Machining (EDM) uses sparks to take away material. Water jet cutting uses strong water to cut metal or stone. Laser cutting uses a laser beam to make very exact cuts. Ultra-short pulse laser ablation uses very quick laser bursts to remove material and make tiny shapes. This is used in making computer chips and small parts. Ablation helps you make very exact features on circuits.

Note: Every way of processing material has its own best use. You pick the right method based on what you are making and the material you use.

Subtractive processing helps you shape parts for many jobs. Cnc machines, laser cutting, and ablation let you make detailed and reliable parts.

Features and Benefits

Advantages

When you choose subtractive manufacturing, you get many important benefits. This method helps you make strong, precise parts for many uses. Here are some key advantages you should know:

You achieve high precision and tight tolerances. This means your parts fit together perfectly.

You keep the strength of the material. The process does not weaken the block, so your parts stay tough.

You get smooth finishes on your parts. This makes them look and feel better.

You can use many types of materials, like metals, plastics, and wood.

You rely on a proven method. Subtractive manufacturing gives you predictable results every time.

You can make many parts quickly. This helps you with large production runs.

You create custom shapes and complex designs. The process lets you adjust for special needs.

Tip: If you need parts that must be strong and exact, subtractive manufacturing is a smart choice.

Surface Quality

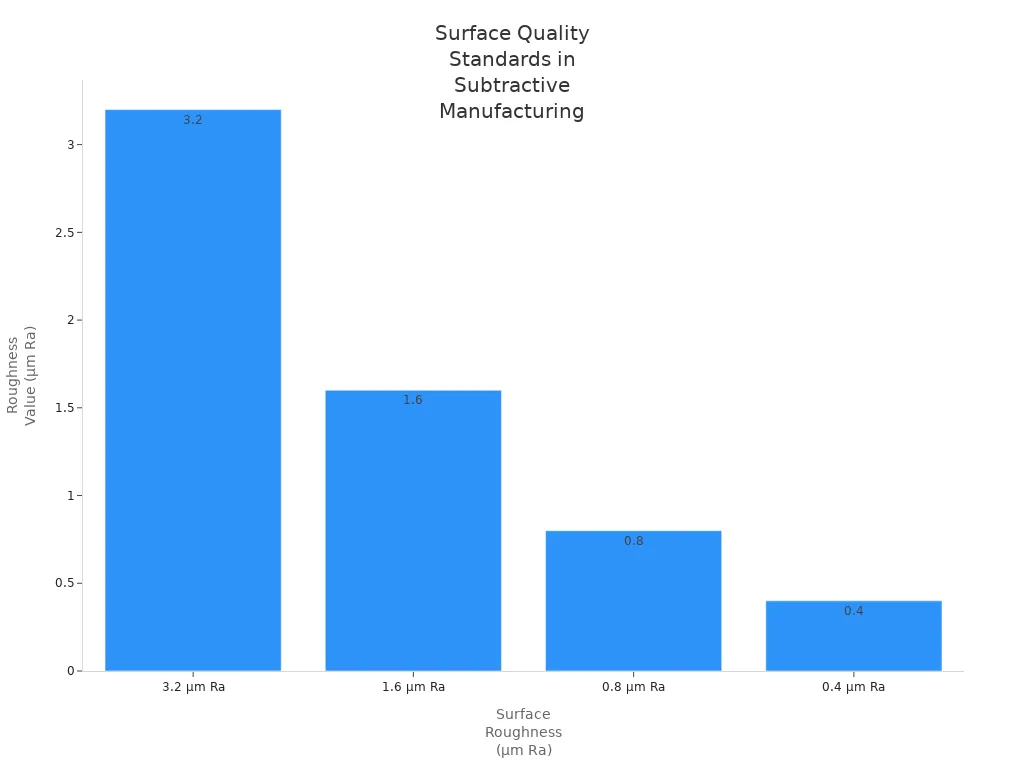

Surface quality matters when you make parts. You want your parts to look good and work well. Subtractive manufacturing helps you reach high standards for smoothness. You can measure surface roughness using a unit called micrometers (μm Ra). Lower numbers mean smoother surfaces.

3.2 |

1.6 |

0.8 |

0.4 |

You often see these roughness levels in finished parts:

3.2 μm Ra

1.6 μm Ra

0.8 μm Ra

0.4 μm Ra

Subtractive manufacturing gives you more choices for surface finishes than additive methods. You use this process for larger items and parts that need a smooth touch. CNC machining is popular because it works fast and gives you many finish options. If you need high-volume production, subtractive manufacturing helps you get the right surface quality every time.

Comparison

Subtractive vs. Additive

You may wonder how subtractive manufacturing is different from additive manufacturing. Both ways help you make parts, but they do not work the same. Subtractive manufacturing starts with a solid block. You remove material to get your part. Additive manufacturing builds parts by adding layers, often using powder.

Here is a table that shows how each method uses material and makes waste:

Manufacturing Type | Material Usage | Waste Generation |

|---|---|---|

Additive Manufacturing | Uses only the necessary material | Creates minimal waste |

Subtractive Manufacturing | Generates leftover chips and scraps | Waste production is almost unavoidable |

Additive manufacturing uses just the amount of material you need. This means there is very little waste. Subtractive manufacturing makes chips and scraps as you cut away extra material. It is hard to avoid making waste with this method.

Additive manufacturing is good for making tricky shapes. Subtractive manufacturing gives you strong parts with smooth surfaces. Each way has its own good points.

When to Use Each

You pick subtractive manufacturing when you need parts that fit together exactly. This process is great for making many parts fast. If you want to use different materials, subtractive manufacturing works well. You also get smooth finishes, which are important for tools and machines.

Here are some times when subtractive manufacturing is the best choice:

You need very exact sizes.

You want to make lots of parts quickly.

You use metals, plastics, or wood.

You need your parts to be smooth.

You want to change designs by updating the program.

Additive manufacturing is best for special shapes and small amounts. You use it when you want to save material and make less waste. Subtractive manufacturing is better for strong, tough parts and making lots of them.

Tip: Think about what you want from your part. If you need it to be strong, smooth, and exact, subtractive manufacturing is usually the best way.

Examples

Everyday Products

Subtractive manufacturing is used to make many things you use. A metal spoon is made by cutting away extra metal from a block. Kitchen knives and scissors are shaped by removing material. The frame of your bicycle is made this way too. If you have a laptop, its metal case started as a solid piece. Machines carve out the shape and leave only what is needed.

Smartphones and tablets have metal parts made by cutting. Buttons, camera rings, and device bodies are shaped this way. Car wheels and engine parts are made by removing material. Some toys are also made with subtractive manufacturing.

Tip: When you see a shiny metal part, remember someone cut away material to make it fit just right.

Applications

Many industries use subtractive manufacturing for important parts. This process is needed when parts must be strong and exact. Here is a table that shows how different industries use this method:

Industry | Applications |

|---|---|

Aerospace | CNC machining for turbine blades, structural brackets, engine housings, and gearbox parts. |

Automotive | Production of engine blocks, brake components, and transmission housings. |

Medical Devices | Creation of implants, surgical instruments, and orthopedic parts from materials like titanium. |

Consumer Electronics | CNC milling for MacBook unibodies and aluminum parts for drones. |

Industrial Equipment | Production of jigs, dies, molds, and fixtures for manufacturing lines. |

Car makers use subtractive manufacturing for engine and transmission parts. This process shapes molds for building vehicles. Airplane builders make brackets and strong parts for flight. These parts must be light and strong.

Car makers shape engine and transmission parts.

Airplane builders make brackets and strong flight parts.

Medical companies create implants and tools that fit perfectly.

You use things made by subtractive manufacturing every day. It shapes the car you ride in and the phone you use.

You can find subtractive manufacturing in many places, like cars and kitchen tools. This process begins with a solid block. Material is taken away to make strong and exact parts. In the next five years, you will see new changes. These include machine learning, smart metals, and green ways to make things. You can learn more by watching videos, reading articles, or looking at books about manufacturing. When you use a spoon or ride your bike, think about how subtractive manufacturing helps make these things.

Future trends are:

New materials that last longer

Green ways to make products

Digital twin technology

Making custom parts when needed

Smart factories using IoT

Ways to learn more:

Videos that show subtractive processes

Articles about how things are made

Books about subtractive manufacturing and composites

FAQ

What is the main difference between subtractive and additive manufacturing?

In subtractive manufacturing, you take away material. In additive manufacturing, you add material. Subtractive starts with a solid block. Additive builds parts one layer at a time. Both ways make parts, but they do it differently.

Can you use subtractive manufacturing for plastic parts?

Yes, subtractive manufacturing works for plastic parts. CNC machines can cut, drill, and shape plastics like they do metals. People use this method for prototypes, custom pieces, and small batches.

Is subtractive manufacturing expensive?

Subtractive manufacturing can cost more for small batches. It uses extra material and makes waste. For big batches, it costs less per part. You save money when you make lots of the same thing.

What safety gear should you wear when using subtractive machines?

Wear safety goggles, gloves, and ear protection. Closed-toe shoes keep your feet safe. Tie back long hair before you start. Safety gear protects you from chips and loud sounds.

Why do industries still use subtractive manufacturing?

Industries use subtractive manufacturing for strong, exact parts. You get smooth surfaces and tight fits. This method works for metals and plastics. Many products need these features.

See Also

Enhancing Manufacturing Efficiency Through Die Blanking Techniques

A Comprehensive Guide to Jigs and Fixtures in Manufacturing

Exploring Casting Shrinkage And Machining Allowances Explained

An Easy Guide to Total Productive Maintenance Concepts

The Importance of SMED in Modern Lean Manufacturing Practices

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.