A Beginner’s Guide to SMED in Manufacturing

SMED stands for Single-Minute Exchange of Die. You use SMED to make equipment changeovers much faster. This method plays a big role in lean and lean production because it helps you save time and cut costs. When you apply SMED, you can see big improvements:

Changeover times often drop to less than 10 minutes.

Many companies have seen a 94% reduction in average changeover time.

Learning SMED gives you a practical tool to boost efficiency and stay competitive.

What is SMED?

SMED Definition

SMED is a term you hear a lot in lean production. It stands for Single Minute Exchange of Die. This method helps you switch from making one product to another fast. You use SMED to make changeovers quick and easy. The goal is to get changeover times under ten minutes. Some people think SMED means less than one minute, but that is not true. You want a simple process that keeps machines working and production moving.

Note: SMED does not mean every changeover takes less than a minute. The real goal is to get most changeovers under ten minutes.

Origin and Purpose

SMED started with Shigeo Shingo, a Japanese engineer. He saw that long setup times caused problems in factories. You may have these problems too:

Machines sit unused for a long time, so you make less.

You need big batches to avoid many changeovers, which means more inventory.

More work-in-process and finished goods use up money and space.

You cannot react fast to small orders or changes in demand.

Customers wait longer for products, which can make them unhappy.

Shingo made SMED to fix these problems. He wanted to help you cut setup times, improve flow, and make production flexible. Long changeover times used to cause bottlenecks and higher costs. SMED helps you make your process faster and meet market needs.

Here is a table that compares SMED with another method:

Methodology | Design Set-Up Efficiency | Total Changeover Time | Advantages |

|---|---|---|---|

SMED | 1070 s | Uses traditional ways and proven methods | |

SSD | 90% | 210 s | Step-by-step, detailed, looks at ease and cost |

You can see SMED is a good way to lower changeover times. Learning SMED helps you start making your manufacturing process better and faster.

SMED in Manufacturing

Why SMED Matters

You have many problems when you want machines to work well. Long changeover times slow you down and cause more stops. SMED helps by making set-up times shorter. You can switch between products much faster. This method is important in lean manufacturing. When you use SMED, your process gets more flexible and works better.

SMED works with other lean tools, like 5S. These tools help you cut waste and get more done.

Here is a table that shows how SMED helps lean manufacturing:

Benefit | Explanation |

|---|---|

Increased production flexibility | Faster changeovers let you make small batches. You can answer customer needs quickly. |

Lower manufacturing costs | Shorter changeovers mean less labor, smaller stock, and less waste. |

Improved equipment effectiveness | Less setup time means machines run longer. This makes Overall Equipment Effectiveness (OEE) better. |

You can see that shorter set-up times save money. They also help you meet customer needs faster. Many companies, like Toyota, use SMED to make quality better and keep customers happy.

Impact on Production

When you try to make changeover time shorter, you see big changes. You wait less for machines to get ready. This means less downtime and more products made each day. SMED helps you cut setup time. You get more cycles and fewer stops for machines.

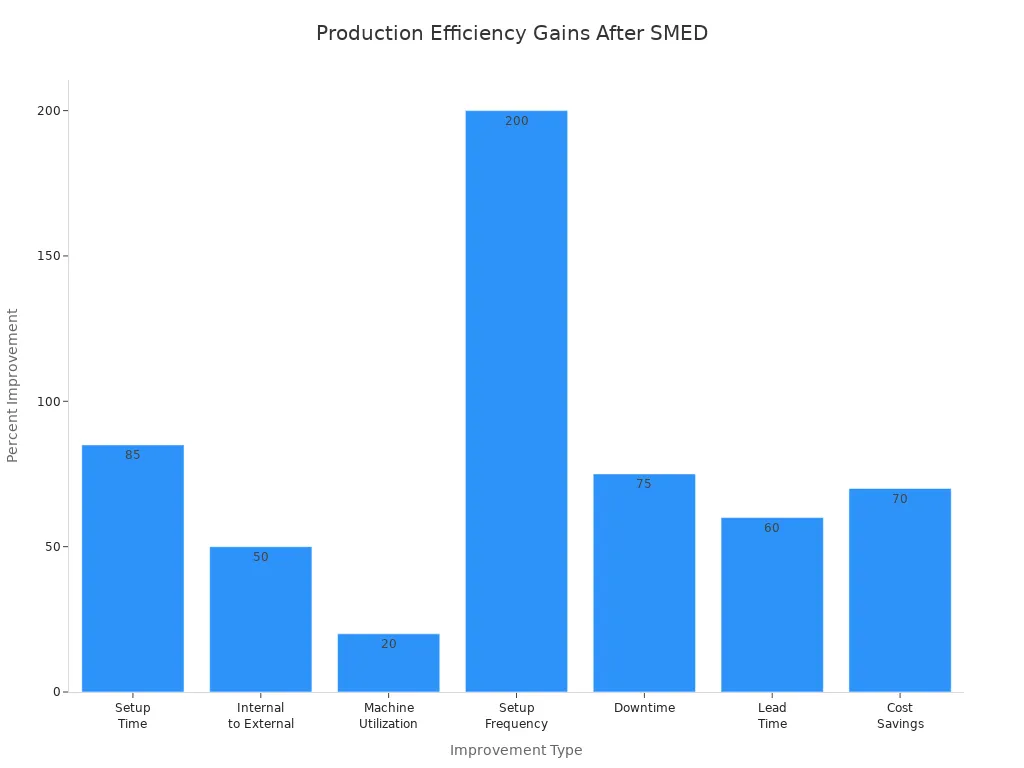

Here is a chart that shows how SMED changes production numbers:

You can see setup time drops from 60 to 9 minutes. Machine use goes up from 70% to 90%. Downtime drops from 2 hours to 30 minutes each day. These changes let you do more setups per shift. You can answer new orders faster.

Different industries use SMED in their own ways. Car factories cut die change time from hours to minutes. Food plants use mobile cleaning stations to speed up changeovers and waste less. Electronics makers use special tool boards to make changeovers fast and keep machines running.

By making changeover time shorter, your process gets faster. You save money and keep machines working longer. This gives you a big edge in today’s fast market.

Single Minute Exchange of Die Process

The main idea of SMED is easy to understand. You want to make changeovers happen very fast. To do this, you look at each step and ask, “Can I do this while the machine is still working?” If you can, you move that step outside the time when the machine is stopped. This is called changing internal activities to external activities. Doing this helps your machines spend less time not working. It also makes your production line able to change quickly.

Internal vs. External Activities

You need to know the difference between internal and external set-up steps. Internal activities are jobs you can only do when the machine is off. External activities are jobs you can do while the machine is running. Knowing this helps you find ways to save time.

Here is a table to help you see the difference:

Type of Activity | Description | Examples |

|---|---|---|

Internal | Activities that require the machine to be stopped. | Removal of guarding, Removal of the old tool, Placing the new tool, Connecting services, Clearing hoppers |

External | Activities that can be performed while the machine is running. | Fetching new tooling, Returning old tooling, Finding tools, Finding paperwork, Fetching raw materials |

When you look at your changeover, try to move as many jobs as you can from internal to external. This is a big part of making SMED work well.

Tip: Always ask, “Can I do this before or after the machine stops?” If yes, make it external.

You can change internal activities to external ones in different ways:

Get cutters ready in a fixture so they are set to use.

Use jigs to set up dies before putting them in the machine.

Preheat dies or materials before the changeover, like race teams heat tires before a pit stop.

Keep extra changeover parts clean and ready, so you do not waste time cleaning during the changeover.

When you move jobs from internal to external, you cut downtime and make changeovers faster. You also help your team work better and stay organized.

Key Steps

Shigeo Shingo, who made SMED, gave clear steps to follow. You can use these steps to make your own changeover better. Each step helps you find and remove wasted time.

Here are the main steps of the SMED process:

Watch the process. Write down every step of your changeover.

Separate internal and external work. List which jobs need the machine stopped and which do not.

Change internal work to external. Move as many jobs as you can to before or after the machine stops.

Make internal work faster. Try to make the rest of the internal steps quicker and easier.

Make external work better. Make the jobs you do while the machine runs simpler.

Write down the new way and teach your team. Make sure everyone knows the new steps.

Keep improving! Always look for ways to get better.

You can use different tools and ideas at each step. Here is a table with some examples:

SMED Stage | Description | Techniques/Examples |

|---|---|---|

Separate | Find jobs you can do while the machine is running. | Getting tools, cleaning, checking quality before changeover. |

Convert | Change more jobs to external or remove them. | Getting parts ready early, using extra jigs, making equipment easier and safer to use. |

Streamline | Make the last jobs faster and easier. | Using quick-release bolts, making settings the same, organizing the workspace, doing jobs at the same time. |

You can also follow these steps in a simple way:

First, separate internal and external set-up jobs. Find out what you can do while the machine runs.

Next, change as many internal jobs as you can to external ones. This saves the most time.

Then, make the rest of the jobs faster and easier. Take away any waste or extra steps.

The single-minute exchange of die method helps you look at every part of the changeover. You can use these steps to make your production faster and easier to change. When you use this method, you will see big changes in your changeover times.

Benefits of SMED

Productivity and Flexibility

SMED helps you work faster and make more products. You can change from one product to another quickly. This means you do not wait long for machines to get ready. You use your machines more and make more things each day. Here is a table that shows how SMED helps you make more products:

Benefit | Explanation |

|---|---|

Reduced Changeover Times | Faster changeovers mean machines stop for less time. You can use them more for making products. |

Enhanced Flexibility | You can make smaller batches and change products more often. This helps you meet what customers want. |

Improved Overall Equipment Effectiveness (OEE) | You can see where to get better by looking at real-time data. This helps you change over faster and make more products. |

You can also react to changes in the market quickly. SMED lets you switch products fast, so you can give customers what they need. Here are some ways SMED helps you be flexible and make more:

Less waiting between runs means you can change products more often.

You can switch products fast to meet what customers want.

SMED and other lean ideas help you keep machines working. They also help you waste less. This makes your process better and keeps your customers happy.

Cost and Waste Reduction

SMED does more than make changeovers fast. It also helps you save money and waste less. When you make changeovers shorter, you spend less in many ways. The table below shows how much you can save:

Changeover Time Reduction | Expected Cost Savings |

|---|---|

50% | Significant |

90% | Significant |

You also cut out many kinds of waste in your factory. Here are some wastes SMED helps you lower:

MUDA of Transport: You move products less.

MUDA of Waiting: Workers and machines do not sit idle as much.

MUDA of Motion: Workers do not have to move around as much.

MUDA of Defects: You make fewer mistakes because setups are better.

Many factories say they cut changeover times by 94% with SMED. Most get changeovers under ten minutes. This means you pay less for workers, use less material, and keep your process simple. You also have less waiting and use your machines more. SMED is a great way to stay ahead and work better.

Implementing SMED

Getting Started

You can begin your SMED journey by following a few clear steps. First, look at your production lines and see where you lose the most productive time. Use real data to find out if changeovers cause a lot of downtime. If they do, SMED can help you with setup time optimization and boost your results.

Here is a simple way to start:

Prepare by learning about SMED and its benefits. Do not rush in without a plan.

Identify where you lose the most time. Use facts and numbers from your shop floor.

Decide if SMED will give you the biggest gains. Focus on areas with long or frequent changeovers.

Pick a pilot area. Choose a machine or process where you can see quick results.

Tip: Start small. A pilot project helps you learn fast and show others the value of SMED.

Training your team is key. You can use workshops to teach everyone about SMED and lean methods. For example, a Job Changeover Optimization Workshop helps teams spot wasted time and improve changeovers. A Quick Changeover Workshop gives hands-on practice and real results. You should also run training sessions that show why reducing downtime matters.

Workshop Name | Description |

|---|---|

Job Changeover Optimization Workshop | Focuses on cutting wasted time and boosting production capacity. |

Quick Changeover (SMED) Workshop | Offers hands-on training to reduce changeover times, often with follow-up support. |

Common Challenges

You may face some hurdles when you start SMED. Getting everyone on board is often the first challenge. Some people may resist change, so you need to show them the benefits. Involve your team in every step. When people help build the new process, they feel ownership and want it to succeed.

Common challenges include:

Gaining support from all stakeholders. Use clear communication and involve everyone.

Collecting accurate data on current changeovers. Without good data, you cannot spot problems.

Analyzing the process deeply. Look for root causes of downtime, not just surface issues.

Making sure improvements stick. Use a structured plan to avoid new problems.

Keeping up the gains. Review your process often and keep improving.

You can overcome resistance by showing how SMED reduces downtime and supports lean goals. Offer high-quality training and let employees share their ideas. When you include everyone, you build a culture of teamwork and ongoing improvement.

Note: Document your SMED process and make it part of your standard work. Review it often and ask for feedback. This helps you keep getting better and stay ahead in lean manufacturing.

You have learned that smed can really help your factory. When you use smed, you get many good things for a long time:

You can answer customer needs faster.

You spend less money to make products.

You make smaller batches and keep less extra stock.

You get better quality and make fewer mistakes.

You earn more money and do better than others.

Benefit | Description |

|---|---|

Reduced Setup Time | |

Flexibility | You can handle new orders and changes in the market quickly. |

Employee Empowerment | Your team helps make things better and brings new ideas. |

Begin using smed now. Each small change helps you build a habit of always getting better.

FAQ

What does SMED stand for?

SMED stands for Single-Minute Exchange of Die. You use this method to make equipment changeovers much faster. The goal is to finish most changeovers in less than ten minutes.

Can you use SMED in any industry?

Yes, you can use SMED in many industries. Car makers, food processors, and electronics companies all use SMED. You can apply the steps to any process that needs fast changeovers.

Do you need special tools for SMED?

You do not always need special tools. You can start by organizing your workspace and moving steps outside machine downtime. Later, you may add quick-release devices or jigs to save even more time.

How does SMED help reduce waste?

SMED helps you cut waiting, extra movement, and overproduction. You make smaller batches and keep less inventory. This means you use less space and money. You also make fewer mistakes because setups become easier.

See Also

Understanding SMED in Lean Manufacturing and Its Importance Today

An Overview of Jigs and Fixtures in Manufacturing

CBAM for Suppliers: A Sustainability Guide in Casting

The Importance of QFD, FMEA, and DOE in Quality Manufacturing

Essential Principles of Lean Manufacturing You Should Know

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.