How Quick Response Methodologies Enhance Efficiency in Engineering and Manufacturing

In engineering and manufacturing, working fast is key to achieving success. Quick response methods play a vital role in streamlining operations by reducing delays and optimizing processes. These approaches emphasize flexibility, enabling quick response quick engineering to adapt swiftly to changes.

Here’s how they enhance production:

Mistakes decrease by 15–40%, resulting in higher-quality products.

Unplanned downtime is reduced by 20–35%, ensuring machines stay operational.

Production output increases by 5–15%, allowing more items to be manufactured.

Quality inspections become more cost-effective, cutting expenses by 10–25%.

New products are developed faster due to clearer and more efficient processes.

By adopting these methods, you can work smarter and faster, paving the way for quick engineering and flexible manufacturing solutions.

Understanding Quick Response Methodologies

Definition and Overview

Quick response methods aim to cut delays and boost flexibility. They help engineers and manufacturers adapt to changes quickly. These methods focus on speed, making processes more efficient. By improving workflows, they help businesses stay competitive.

Studies show how important these methods are today. One study explains how quick response manufacturing improves speed. Another shows how it helps car part suppliers work better. These examples prove that quick response methods save time and use resources wisely.

Relevance to Engineering and Manufacturing

In engineering and manufacturing, quick response methods solve big problems. They shorten wait times, reduce waste, and improve workflows. For example, a biotech company used them to save time and work faster. This proves how these methods can change production for the better.

Using these strategies helps meet customer needs faster. A manufacturing book explains how they give businesses an edge. They help companies adjust to market changes and stay productive.

Quick response methods are more than tools—they are key strategies. They make work faster and smoother, helping industries succeed in today’s fast world.

Key Principles and Methods

Core Principles of Quick Response

Quick response methods are based on key ideas like speed and flexibility. These ideas help make work faster and easier. They also help you handle changes quickly and improve results.

Time-Based Focus: This means cutting down the time it takes to make things. Shorter times let you deliver products faster and meet market needs.

Cross-Functional Collaboration: Different teams work together to fix problems and improve tasks. This teamwork helps everyone aim for the same goals.

Customer-Centric Approach: Making customers happy is very important. By meeting their needs quickly, you can keep them loyal.

Continuous Improvement: Always look for ways to make your work better. This helps you stay ahead in a fast-moving world.

A study showed how companies use agile methods to work better. Even if they don’t call it agile, many already use these ideas. These methods have helped businesses do better, especially when making custom products.

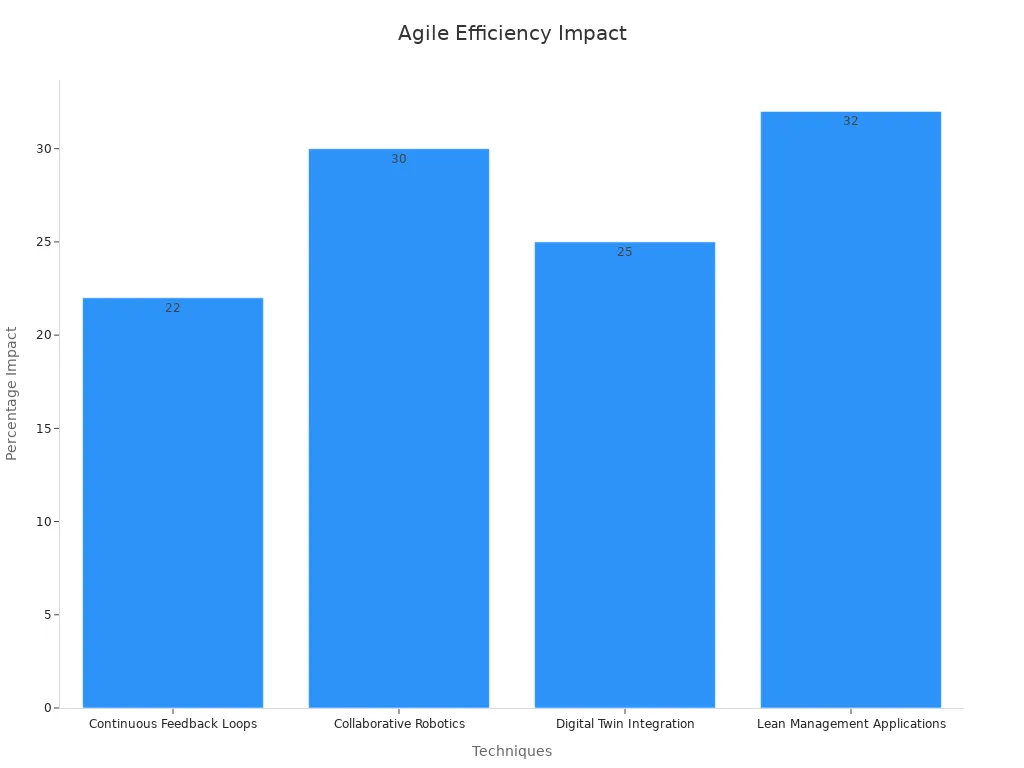

Common Methods and Techniques in Agile Manufacturing

Agile manufacturing uses smart ways to make work faster and better. These methods help you handle changes while keeping quality high.

Technique | How It Helps Production |

|---|---|

Continuous Feedback Loops | Speeds up fixing problems by 22% (Intel, 2023) |

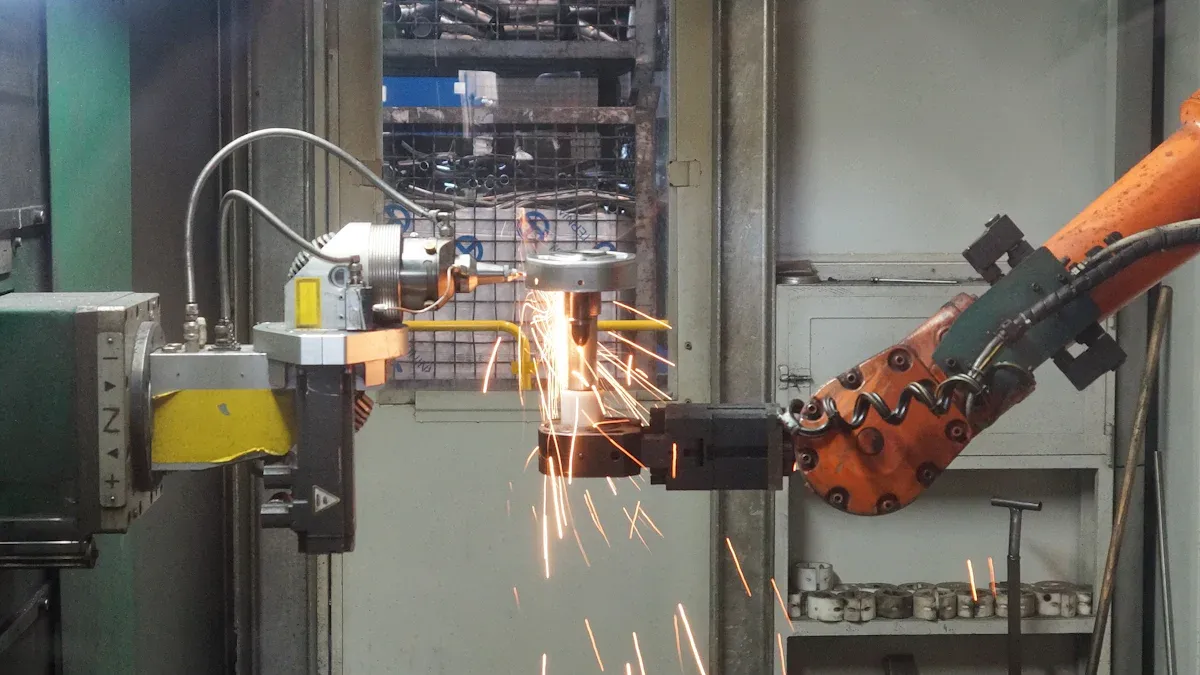

Collaborative Robotics | Boosts work speed by 30% (BMW, 2023) |

Digital Twin Integration | Improves work by 25% (Siemens, 2023) |

Lean Management Applications | Cuts storage costs by 32% (Toyota, 2023) |

Flexible Automation Systems | Adjusts to different work needs |

These methods show how agile manufacturing makes work better. For example, feedback loops help find and fix problems quickly. Robots can do simple tasks, so workers can focus on harder jobs. Digital twins let you test ideas before making changes. Lean management cuts waste and saves money. Flexible systems can change to fit different jobs.

Real-world examples prove these methods work well. Big companies and experts use data to show how helpful agile ideas are. For instance, the FDA uses real-world data to check drug safety. This shows how agile methods improve quality and speed in many industries.

By using these methods, you can save money, work faster, and make customers happy. Agile manufacturing helps you stay competitive by being creative and flexible.

Practical Steps for Implementation

Checking Current Processes for Better Engineering

To use quick response methods well, check your current processes. This helps you find slow spots and areas to improve. Look at how long tasks take to finish. Cycle time shows where things are slow and need fixing. For example, if a task always takes too long, you might need better tools or simpler steps.

Comparing your work to others is also helpful. This is called benchmarking. The table below explains key parts of benchmarking:

Benchmarking Aspect | What It Does |

|---|---|

Performance Comparison | Checks how your work matches up with industry standards. |

Finding Strengths/Weaknesses | Shows what you’re good at and where you can improve. |

Targeted Improvement | Helps you focus on fixing the most important problems. |

Watching Industry Trends | Keeps you updated on new ideas and best practices. |

Using these tools gives you a clear view of your work. This step helps you get ready to add quick response methods to your processes.

Adding Quick Response Methods to Production

After checking your processes, start adding quick response methods. Build a culture where your team always looks for ways to improve. For example, using lean ideas with quick response manufacturing (QRM) can cut waste and make work faster.

Real-life examples show these methods work. Zara, a big fashion company, uses live data to decide on trends and stock. This cuts the time from design to delivery. Zara also keeps less stock to make customers buy faster. Flexible systems help them adjust to changes in demand, keeping work smooth and customers happy.

To do this yourself, focus on teamwork and being flexible. Agile supply chains react quickly, while responsive ones avoid running out of stock. Both focus on improving processes and staying efficient. By using these ideas, you can make your production better and stay ahead in a fast-moving world.

Measurable Benefits of Quick Response Methodologies

Cost Reduction and Profitability

Quick response methods help lower costs by fixing inefficiencies. These strategies cut waste, use resources wisely, and reduce storage costs. For example, just-in-time inventory ensures materials arrive only when needed. This avoids extra storage and stops overproduction.

Lean manufacturing helps find and remove unnecessary steps. This saves money and focuses on important tasks. By skipping unneeded steps, you can use resources better. This leads to more work done and higher profits.

Quick response methods also help you react to market changes faster. Being quick avoids delays and helps grab new chances. Companies using these methods often see better profits. They save money and work more efficiently.

Faster Production Cycles and Lead Time Reduction

Quick response methods make production faster and reduce waiting times. By tracking time-based goals, you can find slow spots and fix them. This helps products move through production quickly, meeting customer needs faster.

A helpful tool for this is Manufacturing Critical-path Time (MCT). MCT measures the longest time it takes to finish an order. The table below explains how MCT works:

Measurement Technique | Description |

|---|---|

Manufacturing Critical-path Time (MCT) | Measures the longest time from order start to delivery of the first piece. |

Using MCT shows where delays happen and how to fix them. Lean practices like teamwork and flexible machines also speed up production. Teams work together smoothly, and machines adjust to changes easily.

Faster production means more products on time. This builds trust with customers and makes your business stand out.

Improved Quality and Customer Satisfaction

Quick response methods improve product quality and customer happiness. Continuous improvement helps find and fix problems early. This ensures products meet customer needs.

Customer feedback is key to knowing what to improve. For example, Agendor learned customers wanted faster responses. They used this feedback to improve their service. Common ways to measure satisfaction include:

Net Promoter Score (NPS)

Customer Satisfaction Score (CSAT)

Customer Effort Score (CES)

"Agendor’s customers shared detailed feedback about their experience. They wanted faster responses from the support team. This helped Agendor improve its service."

By solving customer issues quickly and keeping quality high, you build loyalty. Lean methods like feedback loops help make better decisions. This keeps products meeting market needs and customers happy.

Real-World Uses of Quick Response Quick Engineering

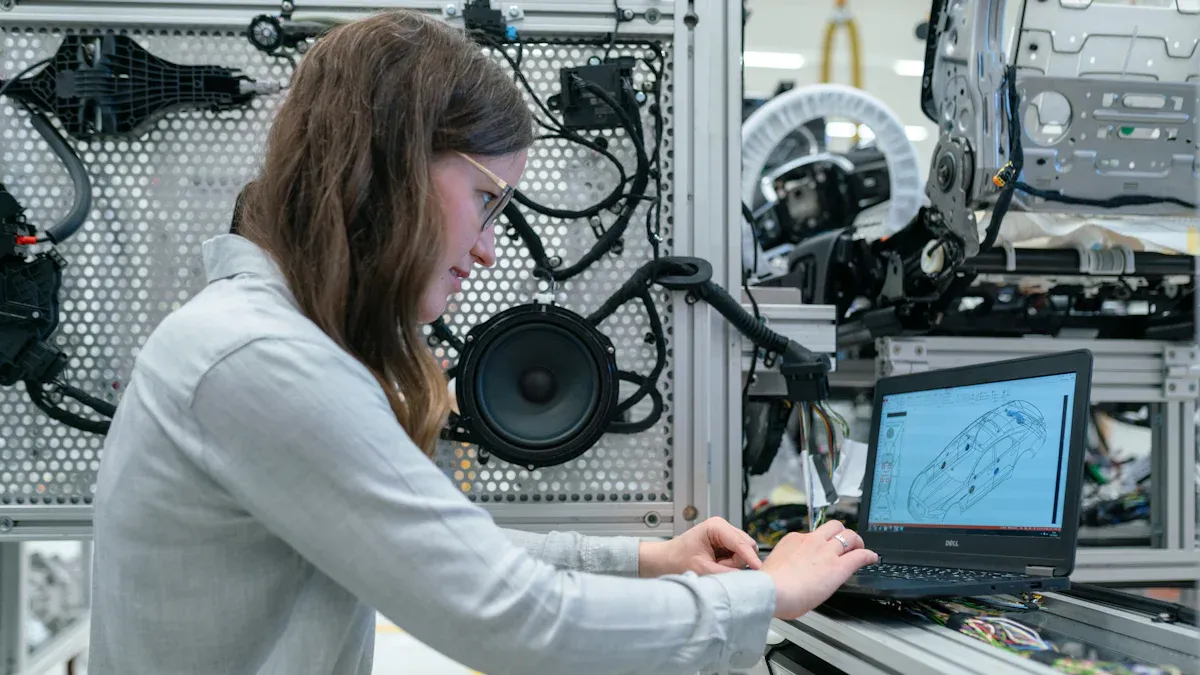

Example 1: Custom Car Manufacturing

Quick response engineering has changed how cars are made. By focusing on what customers want, companies see great results. One helpful method is co-creation. This means customers help design their own cars. It makes customers happy and boosts sales.

The table below shows how custom strategies help industries like cars:

Industry | Custom Strategy | Result |

|---|---|---|

Automotive | Co-creation | Better customer connection and higher sales |

Furniture | Mass Customization | Happier customers and lower costs |

In car making, quick response methods help meet customer needs fast. Using robots and digital tools, companies make custom cars efficiently. This way, customers get unique, high-quality cars, and companies stay productive.

Example 2: Electronics Manufacturing

Electronics companies also benefit from quick response engineering. They face problems like supply chain delays and changing demand. Quick response methods help them adjust and succeed.

Some real examples include:

Chipmakers storing parts to avoid running out.

Sony ordering parts early to stay ahead.

Apple talking closely with suppliers to meet needs.

Using digital twins to see supply issues and fix them fast.

These examples show why quick response methods are important. They help electronics companies stay efficient and meet customer needs. By mixing smart engineering with new tech, they stay strong in a fast-changing market.

Quick response engineering is key for both cars and electronics. It helps businesses adjust quickly, improve work, and deliver great products customers love.

FAQ

What is the purpose of quick response methods?

Quick response methods help make work faster and more flexible. They let you adjust quickly to changes and avoid delays.

How does using real-time data help quick response?

Real-time data shows what’s happening right away. It finds problems early so you can fix them fast and improve work.

Do quick response methods focus on customers?

Yes, they aim to meet customer needs quickly. These methods deliver products faster and keep quality high for happy customers.

Can small businesses use quick response methods?

Yes, small businesses can benefit a lot. These methods save time, cut waste, and don’t need big spending to work well.

How do quick response methods help make more money?

They lower costs by fixing slow steps and wasted time. Faster deliveries make customers happy, which leads to more sales.

See Also

Exploring QFD, FMEA, and DOE's Impact on Quality Control

Defining Functional Testing in CNC and Die Casting Methods

How Cutting Die Blanking Enhances Production Efficiency

Exploring CAE Analysis Advantages for Die Casting Design

Understanding MOQ and Its Effect on RFQ Processes

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.