Comparing Aluminum Casting Quality and Cost for 2025

Have you ever thought about whether spending more on aluminum casting guarantees better results? Maybe you feel unsure about choosing a cheaper option or a more expensive one that claims to be superior. In 2025, understanding the balance of quality vs price can significantly impact your project's success or failure. New aluminum casting technology has changed the landscape. Automated die casting and advanced computer tests enable you to achieve good quality without overspending. Many buyers now prefer aluminum parts made with recycled materials or low-carbon methods. These new trends complicate the decision-making process, but you can still find the best choice that aligns with your quality vs price considerations.

Quality vs Price in Aluminum Casting

Common Myths About Cost and Quality

Some people think paying more for aluminum casting always means better results. This idea seems easy to understand, but it is not always true. Many buyers believe higher cost equals higher quality, but it is more complex than that. Here are some myths you might hear when comparing quality and price in aluminum casting:

Aluminum casting is an old technology. You can get steady results because aluminum has isotropic properties. This means it acts the same in every direction. You do not always need to pay extra for steady results.

Some buyers think all aluminum alloys are alike. But the type of alloy and how it is made can change the quality a lot. Good work during welding and after-treatment also matters.

You may hear that aluminum can be recycled forever and keep its quality. That is not always right. If alloys are not sorted well, recycled aluminum can lose some of its original quality. This can change the final product, even if the price is low.

Tip: Do not let these myths decide for you. Always ask about the alloy, the process, and the team's skill. This helps you balance quality and price and avoid problems.

When Higher Price Delivers Better Results

Sometimes, paying more for aluminum casting really does give better results. You should know when it is smart to spend more. If you want a part with a tricky shape, a smooth surface, or tight sizes, you may need special casting methods. These methods cost more, but they can give you the quality you want.

Here are some times when a higher price can help you:

You need aluminum parts for safety uses, like cars or planes. Here, quality and price are not just about saving money. You want the best quality, even if it costs more.

Your project needs a special alloy or a unique finish. Some buyers need parts that fight rust or handle big stress. Special alloys and finishes can cost more, but they also work better.

You want to avoid trouble later. Sometimes, a cheap aluminum part can break early. If you pay more for better quality, you might save money later because you avoid fixing or replacing parts.

Note: As a buyer, you should always think about what matters most for your project. If you only care about price, you might miss important quality features. If you only care about quality, you could spend too much. The best choice matches quality and price for your needs.

When you look at aluminum casting in 2025, you see more choices than ever. New technology gives you more control over quality and price. As a buyer, you can pick recycled aluminum for a lower price, but you should check if the quality is good enough. You can also choose special casting methods if your project needs top results. The key is to match what you want with the right process and price.

Key Cost and Performance Factors

Tooling and Material Costs

When you look at aluminum casting, tooling and material costs can change a lot depending on the method you choose. Some methods work better for small batches, while others shine in mass production. Here’s a quick breakdown:

Sand casting keeps tooling costs low and works well for small runs. You might pick this if you only need a few parts and want to save money.

Low pressure die casting and shell mould casting cost more than sand casting, but they give you better solidity and a smoother finish. These methods suit medium-sized batches.

High pressure die casting needs a big investment in tooling. If you plan to make thousands or even millions of parts, this method delivers fast results and high quality.

You should always match your project’s needs to the right method. This helps you balance cost and performance.

Production Volume and Lead Time

Production volume plays a huge role in cost and performance. If you make more parts, your cost per unit drops. You also waste less material and can reuse molds, which saves money for big projects.

If you only need a few parts, machining might be cheaper, even though it wastes more material.

Casting methods work best for larger batches because the tooling costs spread out over many parts.

Rapid casting can get your parts ready in as little as 14 days. Die casting takes longer because you need time to set up the tools.

Think about how many parts you need and how fast you want them. This helps you pick the best method for your project’s performance goals.

Part Complexity and Surface Finish

Complex parts need special casting methods. Some techniques handle tricky shapes better than others. Here’s a table to help you compare:

Casting Method | Suitability for Complexity | Production Volume |

|---|---|---|

Die Casting | High precision, detailed parts | Mass production |

Sand Casting | Flexible for complex shapes | Lower volume, big parts |

Investment Casting | Great for intricate designs | Lower volume |

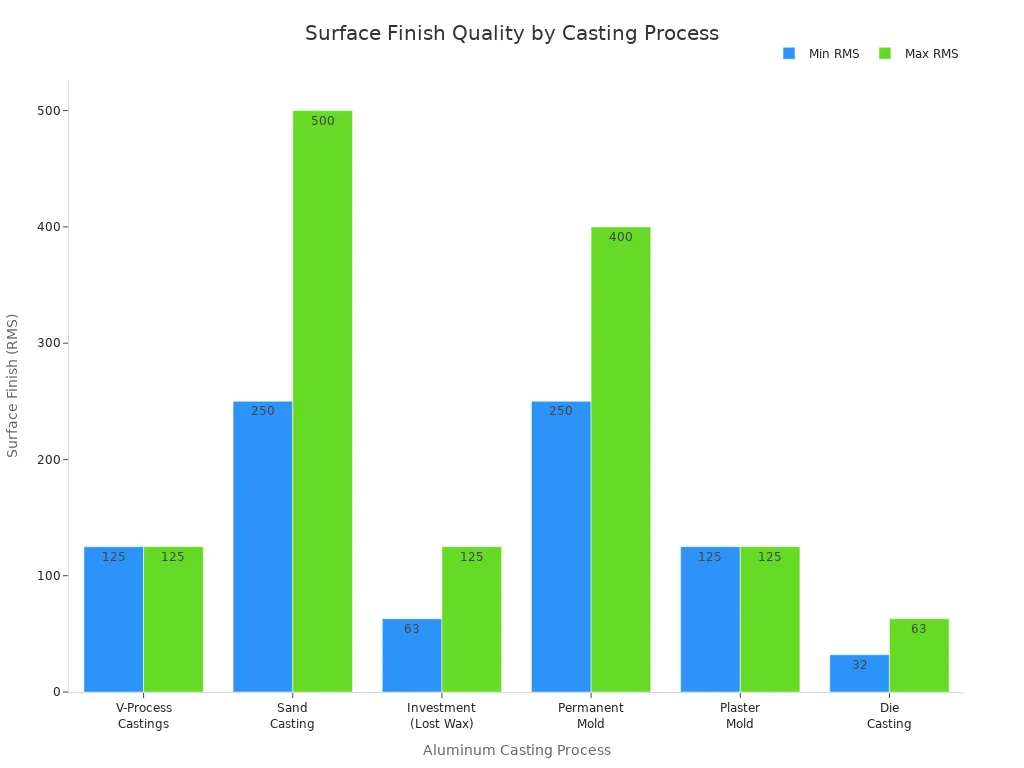

Surface finish matters for both looks and performance. Different casting methods give you different results. Check out this chart to see how they compare:

Die casting gives you the smoothest finish, while sand casting leaves a rougher surface. If you need a shiny part or tight tolerances, pick a method that matches your performance needs.

Tip: Always ask your supplier about the best method for your part’s shape and finish. This helps you get the right cost and performance for your project.

Aluminum Die Casting Methods Compared

High-Pressure Die Casting

High-pressure die casting is good for making parts fast. It works well for thin walls. Strong machines push hot aluminum into steel molds. You get smooth surfaces and tight sizes. Many alloys can be used. This helps stop corrosion and makes coating better. High-pressure die casting is used for car parts, electronics, and tools. Tooling costs more, but you save money if you make many parts. The coating sticks well. You also get good corrosion resistance.

Aspect | Low-Pressure Die Casting | High-Pressure Die Casting |

|---|---|---|

Material | Uses alloys with low melting points | Uses more types of materials |

Weight Range | Parts from 2 to 150 kg | Limited by machine strength |

Strength and Geometry | High strength, complex shapes | Lower strength, good for thin walls |

Wall Thickness | At least 3 mm thick | At least 1 mm thick |

Cycle Speed | Slower casting cycles | Faster casting cycles |

Cost | Lower operating costs | Higher operating and setup costs |

Application Suitability | Not great for thin parts | Good for many uses |

Low-Pressure Die Casting

Low-pressure die casting uses gentle pressure to fill molds. You get strong aluminum parts with tricky shapes. This method is good for wheels, engine parts, and covers. Alloys with low melting points are used. This helps with coating and corrosion. Operating costs are lower, but each part takes longer to make. The coating lasts longer. You see less corrosion.

Gravity Die Casting

Gravity die casting lets hot aluminum flow into molds by gravity. You get castings with fine grain and better strength. Simple molds are used. This method is good for medium batches. Many alloys can be used. This helps with coating and corrosion. You pay less for each part if you make more. Coating works well. Corrosion resistance is strong.

Casting Method | Mechanical Properties | Cost-Effectiveness |

|---|---|---|

Sand Casting | Lower strength from sand mold defects | Higher unit costs, low starting cost |

Permold (Gravity Die Casting) | About 10% stronger from finer grain structure | Cheaper for bigger batches |

Shell Mould Casting | Not mentioned | Not mentioned |

Shell Mould Casting

Shell mould casting uses a thin shell to shape hot aluminum. You get smooth surfaces and good detail. This method is good for small parts and special shapes. Alloys help with coating and corrosion. Mold costs are higher, but you get better coating and less corrosion.

Sand Casting

Sand casting uses sand molds to shape aluminum. You get flexible shapes and big parts. Many alloys can be used. This helps with coating and corrosion. Tooling costs are low. Surfaces are rough and strength is lower. The coating may not last long. Corrosion can be a problem.

Investment Casting

Investment casting uses wax patterns to make detailed aluminum parts. You get high accuracy and smooth surfaces. Special alloys help with coating and corrosion resistance. Each part costs more, but you get top quality. This method is used for aerospace and medical tools.

V-Process Casting

V-process casting uses vacuum to shape aluminum in sand molds. You get smooth surfaces and sharp edges. Many alloys can be used. This helps with coating and corrosion. Setup costs are higher, but you get good coating and less corrosion. This method is good for art, signs, and custom parts.

Tip: Always pick the aluminum die casting method that fits your project. Think about coating, corrosion, alloys, and cost. You get better results when you choose the right casting for your needs.

Quality and Cost Comparison by Method

Mechanical Properties

When you look at aluminium casting, mechanical properties matter a lot. You want strong parts that last. Different casting methods give you different results. Some methods make aluminium parts that can handle heavy loads. Others work better for simple shapes.

Let’s compare two popular choices for automotive applications. You might see die casting used for car parts. It gives high mechanical strength and works fast. Giga casting is a newer method. It makes very large aluminium parts in one piece. This means fewer joints and less chance for defects. Giga casting offers very high strength and can lower assembly costs. Here’s a table to help you see the difference:

Method | Mechanical Strength | Cost Efficiency | Notes |

|---|---|---|---|

Die Casting | High | Moderate | Efficient for producing large parts quickly, but expensive mold changes and quality control issues exist. |

Giga Casting | Very High | High | Allows for production of large components in one piece, reducing assembly costs significantly, but requires large investments in machinery. |

If you need aluminium parts for cars or trucks, you should think about both strength and cost. Giga casting can save money on assembly, but you need big machines. Die casting works well for many shapes and sizes. You get good quality, but you must watch for defects and keep up with mold changes.

Tip: Always ask your supplier about the mechanical properties you need. This helps you pick the right casting method for your project.

Surface Finish and Accuracy

Surface finishing is important for both looks and performance. You want aluminium parts that feel smooth and fit together well. Different casting methods give you different surface finish and accuracy. Some methods make parts with tight tolerances. Others leave rough surfaces that need extra work.

Here’s a quick look at how casting methods compare for surface finishing and accuracy:

Die casting gives you the best surface finish. You get shiny aluminium parts with tight tolerances. This method works well for electronics and car parts.

Investment casting makes very accurate shapes. You get smooth surfaces, but the process costs more.

Sand casting leaves rough surfaces. You might need extra surface finishing to make the part look good.

Gravity die casting gives you better surface finish than sand casting, but not as smooth as die casting.

Shell mould casting and V-process casting also help with surface finishing. You get sharp edges and good detail.

If you care about surface finish cost, you should pick a method that matches your needs. Sometimes, you pay more for better surface finishing, but you save time later. Good surface finishing also helps prevent corrosion and makes coating stick better.

Note: Always check the surface finishing options before you choose a casting method. This helps you get the quality you want without spending too much.

Typical Costs and Value

Casting economics can be tricky. You want good value for your money. Different aluminium casting methods have different costs. Some methods cost more up front, but save money over time. Others work better for small batches.

Let’s break down the typical costs and value for each method:

Die casting needs expensive molds. You pay more at the start, but the cost per part drops if you make many aluminium parts. This method gives you high quality and good surface finishing.

Giga casting costs a lot for machines and setup. You save money on assembly and get very strong parts. This method works best for big projects.

Sand casting keeps costs low. You pay less for tooling, but you might spend more on surface finishing and fixing defects.

Investment casting costs more for each part. You get top quality and smooth surfaces. This method works well for aerospace and medical tools.

Gravity die casting and shell mould casting offer a balance. You pay moderate costs and get good quality.

If you want to save money, think about your batch size and the quality you need. Sometimes, paying more for better casting gives you parts that last longer. You avoid problems and save on repairs. Good casting economics means matching your needs to the right method.

Tip: Always compare the total cost, not just the price per part. Think about surface finishing, defects, and how long the part will last. This helps you get the best value for your project.

Choosing the Right Method for Your Needs

Application-Based Recommendations

Picking the best aluminum casting method can be hard. First, think about what your product must do. Does it need to be strong or light? Maybe it needs a special shape. Look at the sizes and shapes you need. Some aluminum parts must be very exact or have tricky shapes. How many parts do you need? If you want thousands, die casting is a good pick. If you only need a few, sand casting can save money.

Here’s a simple guide for different industries:

Automotive: You want light aluminum parts. These help cars use less fuel and make less CO². Die casting is good for engine brackets and gear cases.

Electronics: Aluminum parts are easy to cast and work well. You find them in phones, computers, and home appliances.

Construction: Big aluminum parts often use sand casting. This method is good for large shapes and costs less.

Tip: Always choose the aluminum casting method that fits your project. This helps you save money and stay on budget.

Decision Table: Method vs. Application

Use this table to compare aluminum casting methods for your needs. It helps you balance quality, cost, and budget.

Application Area | Recommended Method | Why Choose This Method? | Typical Costs | Best for Budget? |

|---|---|---|---|---|

Automotive | Die casting | Good for many parts, tight sizes | High setup | Yes, for big batches |

Electronics | Shell mold casting | Nice detail, smooth surface | Medium | Yes, for small parts |

Construction | Sand casting | Handles big parts, low tool cost | Low | Yes, for large shapes |

Aerospace | Investment casting | Complex shapes, very accurate | High | Yes, for important parts |

Art/Custom | V-process casting | Sharp edges, smooth surfaces | Medium | Yes, for custom jobs |

Always check what you want your product to do. Think about the shape, how many you need, and your budget. This cost guide helps you pick the right aluminum casting method. You get good results and do not spend too much. Your budget stays safe, and your project works out.

Note: If you need more help, ask your supplier for a cost guide. They can help you find ways to save money on aluminum casting.

2025 Trends in Aluminum Die Casting

Innovations in Automation and Alloys

Big changes are coming to aluminum die casting in 2025. Automation is now very important for making parts. Machines can set speed and temperature very well. This helps you make fewer mistakes and waste less material. Data systems keep casting steady and make work safer for people.

New aluminum alloys are also making a difference. Companies like Trimet have made alloys for climate-friendly cars. These alloys use less material and help meet tough emission rules. You can make car parts lighter but still strong. Electric vehicles need more complex aluminum alloys for better performance and less weight.

Additive manufacturing is another trend to watch. This technology helps die casting tools last longer. You can make more parts before changing tools. This saves money and helps you keep up with complex shapes. New surface treatments make parts look better and last longer. You spend less time fixing or replacing them.

Tip: To stay ahead, pick suppliers who use new automation and aluminum alloys. You will get better quality and save money over time.

Sustainability and Cost Savings

Sustainability is now a main goal in aluminum die casting. You can save money and help the planet at the same time. Many companies use thinner walls in their castings. This saves material and lowers carbon emissions. Using aluminum alloys that last longer means you do not change tools as much. This also cuts emissions from making new tools.

Recycling is growing in 2025. Scrap aluminum goes back into the process, so you waste less and use fewer new materials. Some companies buy machines that save energy. These machines use less power and help meet new environmental rules.

Here are some ways to boost sustainability and save money:

Use aluminum alloys that need less energy to make.

Pick casting methods that let you recycle more scrap.

Choose suppliers who follow strict environmental rules.

Try new techniques like rheocasting to use less silicon and make parts stronger.

Note: When you focus on sustainability, you help the environment and save money. This also makes your business stronger for the future.

You have many choices for aluminum casting in 2025. Focus on what matters most for your project—quality, cost, and your goals. Here are some steps you can follow:

Learn the strengths and weaknesses of each casting method.

Check how top suppliers and regions handle quality.

Watch for hidden costs, not just the price tag.

Use market trends to help you decide.

Pick the method that fits your needs and budget. Use this guide to make your next project a success!

FAQ

What is the best aluminum casting method for small batches?

You should try sand casting or investment casting. These methods keep tooling costs low. You can make just a few parts without spending a lot. Sand casting works well for big shapes. Investment casting gives you more detail.

Does recycled aluminum affect casting quality?

Recycled aluminum can work well if sorted and processed right. Sometimes, mixed alloys lower the quality. Always ask your supplier about their recycling process.

Tip: Request a sample before you order a large batch.

How do I know if I need high-pressure die casting?

Pick high-pressure die casting if you want many parts with smooth surfaces and tight sizes. This method works best for automotive, electronics, or tools. If you only need a few parts, try a different method.

Can I save money by choosing a rougher surface finish?

Yes, you can save money if you do not need a smooth finish. Sand casting and gravity die casting cost less. You may need extra work if you want a shiny look later.

See Also

Lightweight Engineering: Aluminium Or Magnesium Die Casting Materials

Evaluating Steel, Titanium, And Aluminum For Robotics Components

Cost Comparison: Plastic Prototypes Against Aluminum Prototypes

Insights On The Automotive Aluminum Die Casting Market 2025

Exploring The Advantages Of Black Anodized Aluminum

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.