The cost-effectiveness of plastic prototypes versus aluminum prototypes

When picking between a plastic prototype and aluminum prototypes, cost matters a lot. For early designs, a plastic prototype is usually cheaper. For example, using XenoWax™, a plastic you can shape, saves 72% to 95% compared to aluminum. A block of XenoWax™ sized 8x8x6 inches costs $64. This saves $323 compared to an aluminum block of the same size. If you make five models, you could save up to $1,934.

Aluminum prototypes are stronger and more precise. They handle tough tests and give accurate results. This makes them great for projects needing high performance. Your decision depends on your project’s needs and budget.

Cost Analysis

Upfront Costs of Plastic Prototypes

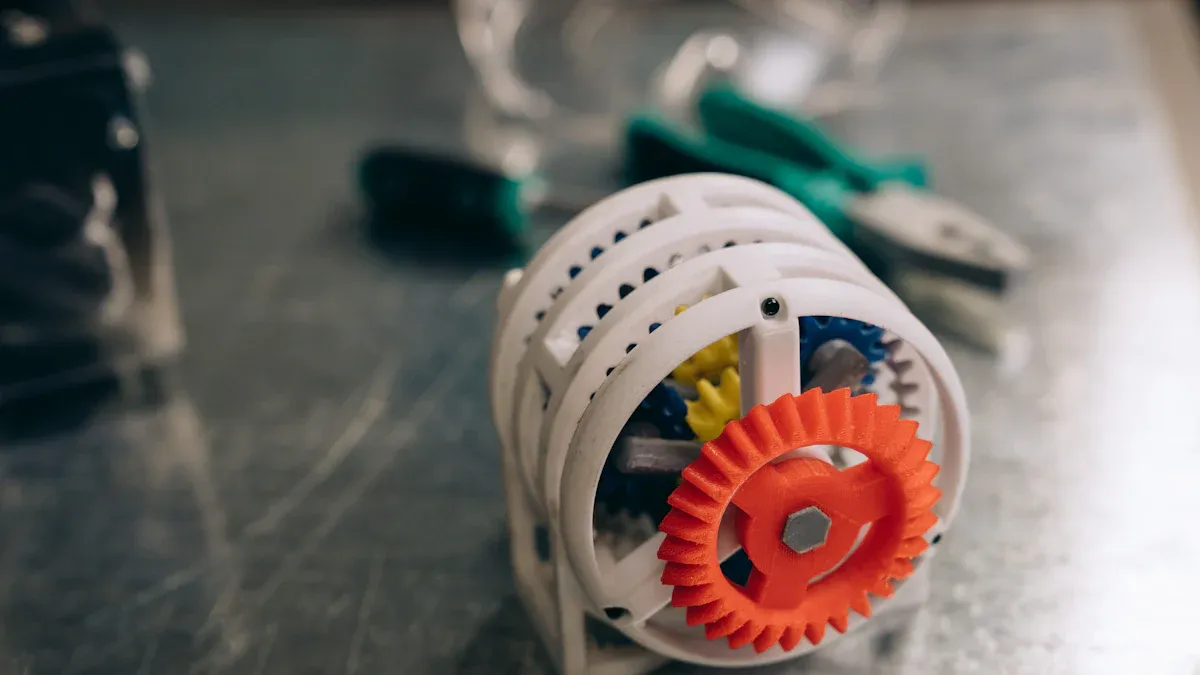

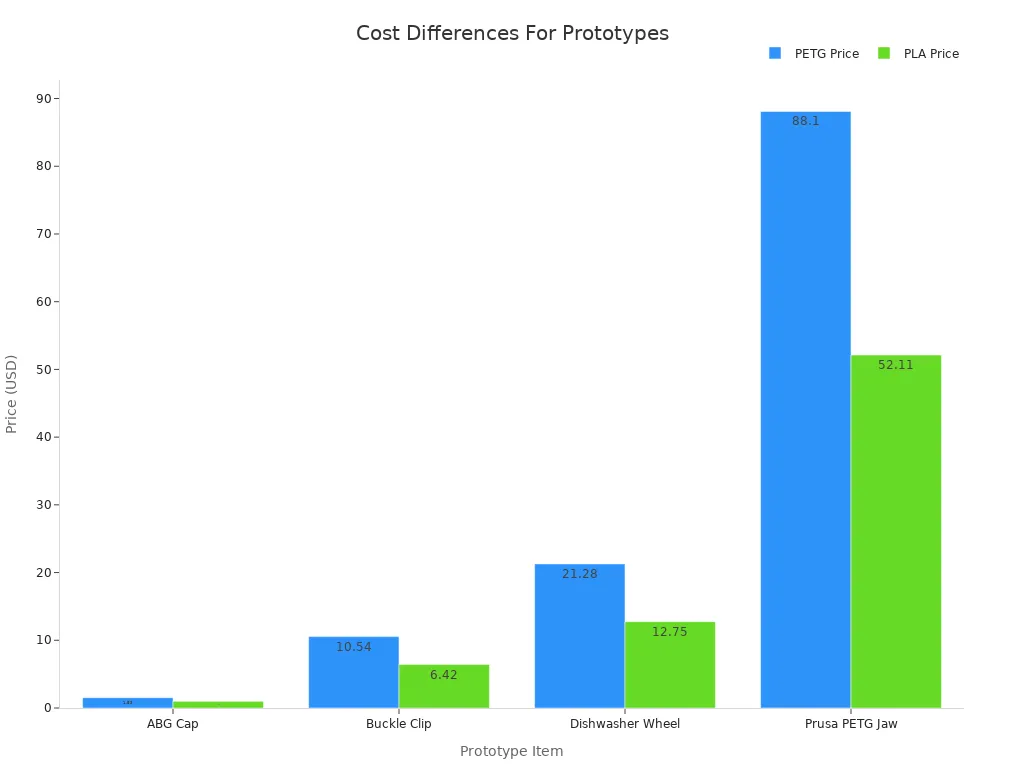

Plastic prototypes are a popular choice for early designs because they are cheaper. The cost depends on the material and how they are made. Common materials like PETG and PLA are often used in 3D printing. Below is a table showing their prices for different items:

Prototype Item | Price for PETG | Price for PLA |

|---|---|---|

ABG Cap | $1.53 | $0.98 |

Buckle Clip | $10.54 | $6.42 |

Dishwasher Wheel | $21.28 | $12.75 |

Prusa PETG Jaw | $88.10 | $52.11 |

The table shows that PLA costs less than PETG. For small production runs, prices range from $20 to $200 per part. This makes plastic prototypes great for small projects. Complex designs, like engineering models, can cost between $2,000 and $250,000. Even with these differences, plastic prototypes are still affordable for most uses.

Upfront Costs of Aluminum Prototypes

Aluminum prototypes cost more but have benefits that make them worth it. The higher price comes from aluminum's strength and durability. Here are some important facts:

Metric | Value |

|---|---|

Global Aluminum Castings Market | |

Forecasted Market Value | US$ 171 billion by 2033 |

CAGR | 6.2% over the next ten years |

Initial Investment Challenge | High initial investments required for manufacturing aluminum castings |

For medium production (1,000 to 5,000 units), costs range from $2,000 to $5,000. Large runs of 10,000+ units can cost $5,000 to $100,000. These numbers show aluminum prototypes need a bigger upfront investment. They are better for projects needing strong and precise parts.

Production Costs and Scalability

Both plastic and aluminum prototypes have pros and cons for production costs and scaling. Plastic prototypes are great for making many parts because injection molding is cost-effective. While setup costs are high, making more parts lowers the overall cost. This makes plastic prototypes ideal for producing thousands of items.

Scalability Factors for Plastic Prototypes:

Injection molding works well for large quantities.

Better designs and materials can save money.

Good supply chain management helps with fast production.

Aluminum prototypes are less suited for large-scale production because of higher costs. But they are perfect for projects needing strong and accurate parts. Quality checks are important for both materials to avoid waste and extra costs during scaling.

Durability and Functionality

Durability of Plastic Prototypes

Plastic prototypes are not as strong as aluminum ones. They work fine for light use but may fail in tough conditions. The strength depends on the type of plastic used. For instance, ABS plastic is stronger than PLA. Even strong plastics can break under high heat or pressure. Think about where the prototype will be used. If it faces heavy loads or heat, plastic may not be ideal.

Plastic prototypes can also wear out over time. Scratches and dents happen with frequent use. Still, they are good for short-term use or testing simple designs. Their low cost makes them a smart choice for early development.

Durability of Aluminum Prototypes

Aluminum prototypes are very strong and last longer. They resist damage, making them great for tough testing. Aluminum can handle heat, heavy loads, and harsh conditions without bending. This makes it perfect for industries like cars and airplanes. Aluminum prototypes outlast plastic ones.

Another benefit is that aluminum doesn’t rust. This helps it last longer, especially in wet or chemical-filled places. If you need a strong and durable prototype, aluminum is worth the cost.

Functional Testing with Plastic Prototypes

Plastic prototypes are useful for testing designs early on. They help check if parts fit and work together. For example, you can see if pieces align or a mechanism works. This helps find problems before using expensive materials.

But plastic prototypes don’t handle stress well. They are best for testing light or simple parts. For heavy-duty designs, you may need stronger materials later. Even so, plastic prototypes are a cheap way to improve your design.

Functional Testing with Aluminum Prototypes

Aluminum prototypes are great for testing because they are strong and precise. They work well when checking how a product performs in real-life situations. These prototypes can handle tough tests without breaking. This makes them perfect for industries like airplanes, cars, and big machines.

Testing aluminum prototypes uses advanced methods to check quality and performance. Here are some important parts of the process:

Stress Testing: Aluminum prototypes face high pressure or heat to find weak spots. This ensures the final product can survive tough conditions.

Material Analysis: Engineers check the aluminum to make sure it is high quality. This step avoids problems that could make the product weaker.

Defect Detection: Special tools find surface flaws or design mistakes. Fixing these early prevents bigger issues during production.

Tip: Aluminum prototypes are best for testing products that need to handle heavy loads or rough environments. They act like the real product, making them helpful for improving designs.

The data from testing shows where changes are needed. For example, if there are repeated flaws, the manufacturing process might need fixing. Solving these problems early saves time and money later.

Aluminum prototypes are a dependable way to test and improve designs. Their strength and accuracy help ensure your product is ready before it is sold. If your project needs tough testing, aluminum is a smart pick.

Speed and Ease of Production

Production Speed of Plastic Prototypes

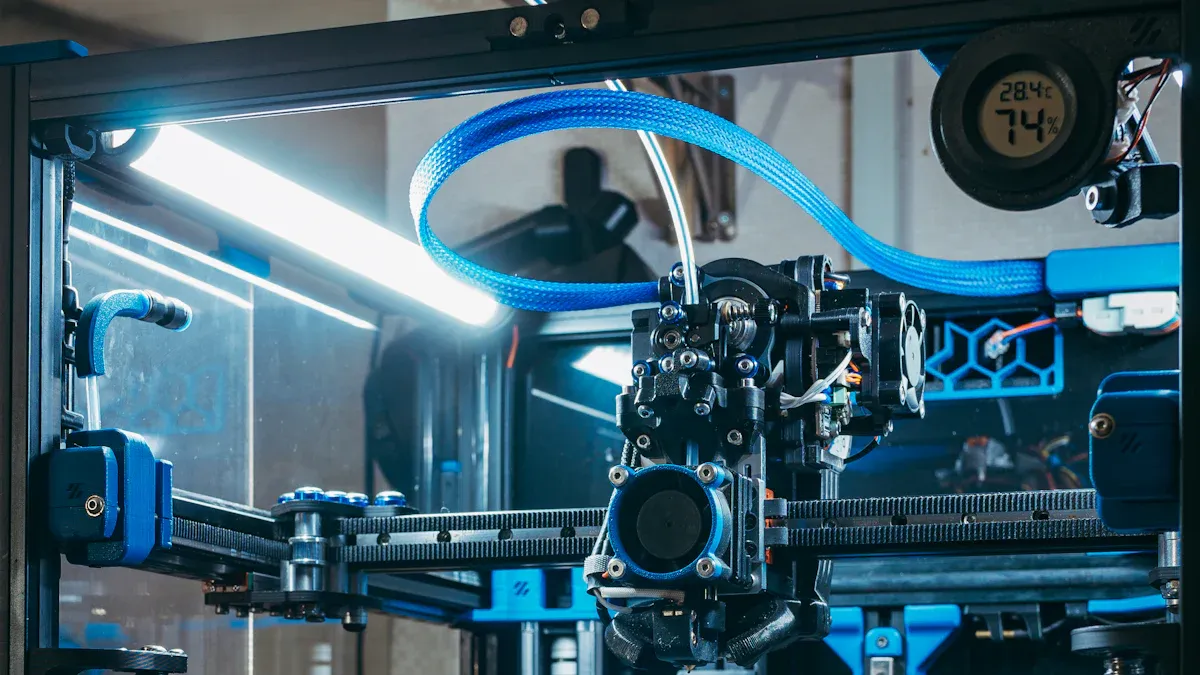

Plastic prototypes are made quickly using modern methods. On-demand production creates parts only when needed, saving time. CNC machines turn digital designs into prototypes in just days. This helps make changes fast, perfect for projects needing updates often. Unlike older methods like injection molding, these techniques are faster and cut waiting times.

Benefits of fast plastic prototype production:

On-demand production is quick and flexible.

CNC machines create prototypes in a few days.

Fast changes improve designs quickly.

Production Speed of Aluminum Prototypes

Aluminum prototypes are made fast with CNC machines and 3D printing. These tools create prototypes in hours or days, not weeks. For example, rapid prototyping with aluminum speeds up making complex designs. Tests show laser power affects production speed. Stronger lasers, like 1720 W or 1800 W, make strong, high-quality parts quickly. This ensures both speed and accuracy in production.

Note: Aluminum prototypes are great for projects needing fast and precise results.

Manufacturing Complexity of Plastic Prototypes

Plastic prototypes are easy to make and work for many uses. Methods like 3D printing and injection molding make creating detailed designs simple. Plastic materials are flexible and can be shaped into many forms. Their lightweight nature also makes handling easier during production. While some designs need special tools, making plastic prototypes is simpler than aluminum.

Tip: Pick plastic prototypes for projects needing fast and simple production.

Manufacturing Complexity of Aluminum Prototypes

Making aluminum prototypes is harder than making plastic ones. Aluminum needs special tools and skilled workers to shape it. Methods like CNC machining, die casting, and 3D printing with metal powders are common. These methods take more time and need careful planning.

CNC machining uses computer programs to cut aluminum into shapes. Mistakes in programming can ruin the prototype and waste materials. Die casting melts aluminum and pours it into molds. This works well for making many parts but needs perfect molds for good results. 3D printing is great for detailed designs but costs more and takes longer.

Studies show how tricky aluminum prototype production can be. Below is a table with key findings:

Study Title | Key Findings | Statistical Evidence |

|---|---|---|

Casting of complex structures in aluminum using gypsum molds produced via binder jetting | Casting techniques show challenges in aluminum production | |

Aluminium deep drawing with additive manufacturing polymer punches | Polymer punches help shape aluminum with fewer errors | Dimensional changes in cups were small (0.002 mm and 0.3 mm losses) |

These studies prove aluminum prototypes need high precision. Even tiny errors, like those in the second study, can affect quality. You must think about these details when picking aluminum for your project.

Though harder to make, aluminum prototypes are strong and accurate. If your project needs tough and reliable parts, the extra effort is worth it. Knowing the process helps you plan better and avoid mistakes.

Application-Specific Considerations

Best Use Cases for Plastic Prototypes

Plastic prototypes are great when saving money and flexibility matter. They work well for early product designs to test simple functions. Industries like healthcare, education, and consumer goods use them because they are cheap and easy to make. For example, in medical devices, 3D printing helps improve designs quickly.

Plastic prototypes are best for light parts that don’t carry weight. They are also good for making detailed shapes that are hard with other materials. Below is a table showing key points about plastic prototypes:

Title | Description |

|---|---|

Digital Manufacturing Guides | Talks about materials for prototypes, including plastics. |

3D Printing Trend Report 2024 | Shows new ideas in 3D printing for plastics. |

Medical and Health Care Applications | Explains fast production of medical devices using plastic prototypes. |

If you need quick changes and low-cost options, plastic prototypes are a smart pick.

Best Use Cases for Aluminum Prototypes

Aluminum prototypes are best for projects needing strength and accuracy. They are used in industries like cars, airplanes, and electronics. For example, Addman Engineering uses 3D printing to make strong aluminum parts for planes. These prototypes are high-quality and save time, making them great for tough jobs.

Aluminum is light but strong, making it good for parts needing both. It also resists rust and handles heat well, which is useful in special industries. Common uses include:

Aerospace: Strong, light parts like brackets and housings.

Automotive: Durable parts like engine components.

Consumer Electronics: Sleek designs using aluminum’s flexible and shiny look.

If your project faces tough conditions or heavy use, aluminum prototypes are reliable.

Combining Plastic and Aluminum Prototypes

Using both plastic and aluminum prototypes can improve your project. Plastic is good for quick changes early on, while aluminum is strong for final tests. This mix saves money and ensures good performance.

This method works well for projects needing many changes. Parts made from strong plastics and metals look good and last long. But some shapes may need adjustments during production. Here are the benefits of combining materials:

Fast Prototyping: Custom parts can be ready in a day.

Improved Testing: Testing and fixing designs lowers costs.

Reduced Risks: Using both materials avoids problems and improves designs.

By using both plastic and aluminum, you can save time and money. This approach helps your product meet its goals while staying efficient.

FAQ

1. Which prototype material is better for beginners?

Plastic prototypes are great for beginners. They are cheaper and simpler to make. You can test ideas quickly and fix mistakes easily. This makes them perfect for learning and trying new designs.

2. Can aluminum prototypes be used for small projects?

Yes, but they might cost too much. Aluminum works well for strong and precise designs. For smaller or simpler projects, plastic is cheaper and faster to use.

3. How do I decide between plastic and aluminum prototypes?

Think about your project’s needs. Pick plastic for low cost and flexibility. Choose aluminum for strength and accuracy. Look at your budget, testing needs, and how many parts you need.

4. Are plastic prototypes environmentally friendly?

Some plastics, like PLA, break down naturally and are eco-friendly. But many plastics can’t be recycled. Check the materials to reduce harm to the environment.

5. Can I combine plastic and aluminum in one project?

Yes, using both materials can improve your project. Plastic is good for early tests, while aluminum works for strong final parts. This mix saves money and gives better results.

Tip: Combining materials helps keep costs low and quality high.

See Also

Exploring The Elements That Affect Die Cast Mold Pricing

The Advantages Of CAE Analysis For Die Casting Design

Essential Trends In The 2025 Automotive Aluminum Die Casting

Enhancing Diecast Product Longevity Through Electroplating Techniques

A Comprehensive Guide To CAD Design For Die Casting

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.