Understanding One Piece Flow and Its Importance

You can use one piece flow to move each product step by step. There is no waiting between steps. One-piece flow helps you find mistakes fast. You can fix problems before they get worse. One piece flow keeps inventory low. This means you do not waste space or money. The process also makes your workspace safer. It stays neat and free of clutter. Customers get their products faster. The products are also better quality. Look at the table below to see how one piece flow helps with efficiency, quality, and waste:

Benefit | Description |

|---|---|

Efficiency | One piece flow stops delays by moving products all the time. |

Quality | One-piece flow lets you find mistakes early and stop extra work. |

Waste Reduction | One piece flow keeps inventory small and cuts down on extra stock. |

Key Takeaways

One piece flow moves products one step at a time. There is no waiting between steps. This helps workers find mistakes fast. They can fix problems right away.

This way of working lowers the amount of inventory. It saves space and money. The workspace stays clean and safe.

One piece flow helps people work better. It makes lead times shorter. It helps workers get more done. Customers get their orders faster.

Using one piece flow makes products better. Workers find mistakes early. Customers get higher quality products.

Flexibility is a big advantage. You can switch between products easily. You can meet customer needs fast. There is no wasted time.

One Piece Flow Explained

Definition

One piece flow means you move each product through every step. You do not stop between steps. When you finish one step, you send the item to the next right away. The next station must be ready to take it. You do not wait for a group of items to finish. Items keep moving in small steps all the time. You do not need to make big batches. Each product goes from start to finish on the shortest path. One piece flow helps you wait less and waste fewer materials. Your workspace stays neat and free of mess.

One piece flow started in 1934. Kiichiro Toyoda wanted to find engine problems fast. He called it “one-by-one confirmation.” Today, you can use one piece flow to spot problems early and fix them before they get worse.

Key Principles

You follow some important rules when you use one piece flow. These rules help you get the best results:

Keep Work-in-Process (WIP) Inventory low. You do not let unfinished goods pile up. This saves space and money.

Keep units moving all the time. You move each item through every step without waiting. You find mistakes fast and can change if needed.

Use a cellular manufacturing layout. You put machines and workstations in a good order. This setup cuts down on moving and waiting.

You can see big changes when you use these rules. One study showed that one piece flow got rid of all WIP inventory. You saved 216 minutes of wasted time. Another example showed costs went down from $200,000 to $180,000 after using continuous flow.

Batch vs. One Piece Flow

You might wonder how one piece flow is different from batch production. The differences are easy to see in efficiency, flexibility, and quality control.

Feature | One Piece Flow | Batch Production |

|---|---|---|

Short | Long | |

Inventory | Low | High |

Flexibility | High | Lower |

Quality Control | Immediate feedback | Delayed detection |

Space Requirement | Less | More |

With one piece flow, you make one item at a time. You move each product to the next step as soon as it is done. In batch production, you make a group of items before moving them forward. If there is a problem in batch production, it can ruin the whole group. You might waste time and materials if you find a mistake late. With one piece flow, you catch mistakes right away. Only one item is affected, so you waste less.

Here is a simple example. You make peanut butter and jelly sandwiches. With one piece flow, you finish each sandwich and give it to the customer. If the customer wants a different jam, you can change it. You get paid right away. With batch production, you make all the sandwiches first. If someone wants a different jam, you cannot change it. You might have to throw away sandwiches and start again. One piece flow lets you change fast and waste less.

Modern factories use technology to help one piece flow. Software like FactoryLogix and ShopVue lets you track production as it happens. These tools help you watch the workflow, cut lead times, and work better.

Software Solution | Description |

|---|---|

FactoryLogix | Lets you see and control everything in real time. You can watch and improve production as it happens. |

ShopVue | Tracks production as it goes. You cut lead times and make work smoother. |

Smart Factory | Makes production better, cuts downtime, and helps you work faster. |

One piece flow is more than just a method. It is a way to make your process faster, safer, and easier to change. You give better products to your customers and spend less money.

Benefits of One-Piece Flow

Efficiency

One piece flow helps you work faster. Products move from one step to the next right away. You do not wait for a group to finish. Each item goes forward as soon as it is ready. This keeps things moving and helps you finish work quickly. You can deliver products sooner.

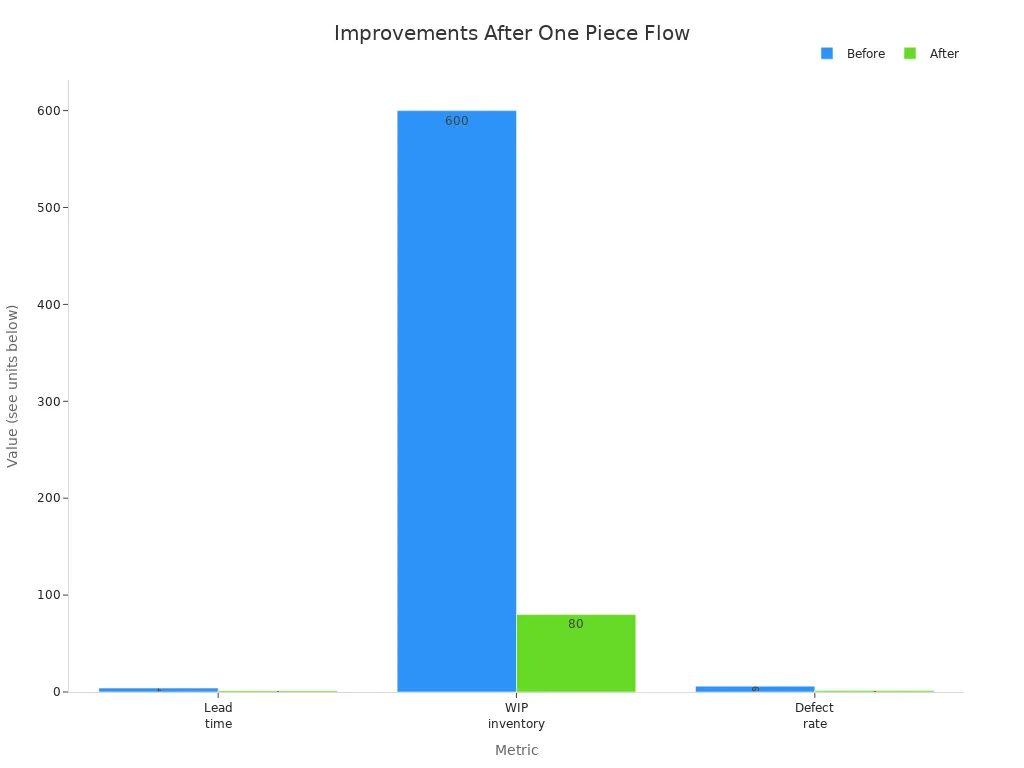

Check out the table below. It shows how one piece flow makes things better in a real factory:

Metric | Before | After |

|---|---|---|

Lead time | 4 days | 1.2 days |

WIP inventory | 600 units | 80 units |

Defect rate | 6% | 1.5% |

Productivity | N/A | Up 28% |

You can also see these changes in the chart:

One piece flow cuts lead times and lowers unfinished products. You spot problems fast. You spend less time fixing mistakes. You make more good products. You save money because you do not store extra parts. Your team works together better. You meet customer needs faster.

Quality

One piece flow helps you make better products. You find mistakes right away. Problems do not move down the line. You fix issues before they get bigger. You do not need to check a whole group for errors. You only look at one item at a time.

In batch processing, you might miss mistakes because there are too many items.

With one piece flow, you catch mistakes fast and fix them quickly.

You match your work to what the customer wants, so you do not make extra products.

You waste less and keep quality high.

One piece flow also makes your workplace safer. You keep your area clean and neat. You do not have piles of unfinished work. This lowers the risk of accidents and makes it easier to see problems. The table below shows how one piece flow helps safety:

Evidence Description | Impact on Workplace Safety |

|---|---|

One-piece flow focuses on employees’ efforts on the manufacturing process itself. | Reduces waiting and transporting time, minimizing distractions and potential hazards. |

It reduces the damage that can occur to product units during batch processing. | Less damage leads to fewer accidents related to handling defective products. |

It reveals any defects or problems in product units early in the production process. | Early detection of issues prevents the continuation of unsafe practices and reduces the risk of accidents. |

Immediate inspection of products after each process. | Allows for quick identification of failures, preventing the production of faulty items that could cause harm. |

Waste Reduction

One piece flow helps you cut waste. You only make what you need, when you need it. You do not build up extra inventory. This is a big part of lean manufacturing. You use less space, fewer materials, and less time.

Time waste drops by about 60% in zero-waste one piece flow projects.

Even in other cases, you can cut time waste by 30%.

Companies see profits rise by over 40% when they use one piece flow for waste reduction.

One piece flow links each step in your process. There is no waiting between steps. You move each item forward right away. This keeps inventory low and helps you use materials better. You do not have to store extra parts or worry about things getting lost or broken.

Tip: One piece flow lets you see where waste happens. You can fix problems fast and keep your process running smoothly.

Flexibility

One piece flow gives you more flexibility. You can switch from one product to another quickly. You do not need to finish a whole group before you make changes. If a customer wants something different, you can adjust right away.

Benefit of One Piece Flow | Explanation |

|---|---|

Allows for quick adaptation to changes in demand or production schedules. | |

Individual production | Producing items one at a time eliminates the need to rework large batches. |

Enhanced responsiveness | Increases the ability to meet customer demands efficiently. |

You can adapt to new orders or changes without stopping everything.

You do not waste time or materials on products customers do not want.

You respond faster to customer needs and market changes.

One piece flow makes your process simple and easy to change. You do not have to move big boxes or containers. You focus on making each product right the first time. This flexibility helps you stay ahead in a fast-changing market.

Note: One piece flow is not just for factories. You can use it in any process where you want to improve speed, quality, and customer satisfaction.

Implementing One Piece Flow

Assess Process

Before you start using one piece flow, you need to look at your current process. You should find areas that slow down your work or cause problems. Make sure you have the right equipment, like conveyor belts or storage bins, to help items move smoothly. Train your team so everyone understands how one-piece flow works and how to use new tools. Start with small changes and watch how things go. Keep checking your process and make changes when needed.

Look for steps that waste time or materials.

Invest in tools that help items move from one step to the next.

Teach your team about one piece flow and new equipment.

Make changes slowly to avoid mistakes.

Watch your process and fix problems as they come up.

Tip: Careful planning helps you avoid surprises and keeps your process running well.

Transition Steps

When you move from batch production to one piece flow, you need a clear plan. The table below shows steps you can follow to make the change easier:

Step | Description |

|---|---|

1 | Find the biggest limits in your process that slow down flow and set the right pace for your work. |

2 | Decide how often you need to make each product, like daily or weekly. |

3 | Change batch sizes into lead times so you can see where delays happen. |

4 | Use planning that groups orders smartly, so you do not force big batches for each product. |

5 | Keep your workshop flexible so you can group orders in the best way. |

You can use these steps to help your team switch to one-piece flow. This method lets you spot problems early and fix them fast.

Overcoming Challenges

You may face some problems when you start using one piece flow. Some common issues include trouble getting the right materials, machines breaking down, or workers not liking the new way of working. Sometimes, workers do not know how to do different jobs, or it takes too long to switch between tasks. You might also find that your machines are not made for one-piece flow, or that your process stops when there are defects.

You might not get materials in the right amount or at the right time.

Machines can break down and cause delays.

Workers may not want to change how they work.

Some workers may not know how to do more than one job.

Changing from one task to another can take too long.

Steps in your process may be too far apart.

Defects can stop the whole line if you do not have buffers.

Some steps may take longer than others, causing slowdowns.

Machines may not fit one piece flow.

Work can get interrupted, making it hard to keep items moving.

To solve these problems, you can use automation tools that keep your process running without stops. You can also combine systems to make your work easier and use tools that fit with what you already have. The table below shows some solutions:

Solution | Description |

|---|---|

Seamless Automation | Use software to keep work moving without breaks. |

System Consolidation | Combine different systems to make your process smoother. |

Integrated Solutions | Pick tools that work with your current setup to make things easier and faster. |

Note: One piece flow is a key part of lean manufacturing. When you plan well and solve problems early, you can make your process faster, safer, and better for everyone.

One Piece Flow in Action

Case Study

New Balance used batch and queue processing before. This made work slow. Orders took a long time to finish. Inventory kept growing and filled up space. New Balance switched to one piece flow. This change helped remove extra inventory. Shoes moved through each step without waiting. Production speed got better. The company reached 24 inventory turns each year. Retailers could get shoes 98% of the time.

Here is a table that shows what changed after New Balance used one piece flow:

Metric | Before (Days/Units) | After (Days/Units) | Improvement |

|---|---|---|---|

Overall waiting time | 24.84 | 16.75 | |

Overall WIP | N/A | N/A | Reduced by 36% |

Defects | N/A | N/A | Reduced by 40.51% |

Manpower | 73 | 68 | Reduced by 6.85% |

Cost savings | N/A | N/A | US $0.61 million |

One piece flow helped New Balance save money. It lowered defects and made production faster.

Lessons Learned

Using one piece flow teaches many lessons. You see waste quickly when work-in-process is low. This helps you fix problems fast. Workers focus on tasks that matter. Productivity goes up. Operations run smoother with fewer slow spots. Teams can spot waste and make work better. This helps everyone keep improving.

You make your workflow simple by cutting extra steps.

Lead times go down, so customers are happier and costs drop.

Workers help find waste, so everyone learns how to improve.

Efficiency gets better because bottlenecks are smaller.

Teams talk every day to solve problems and make things better.

One piece flow works in many places. You can use it in assembly lines, electronics, food packaging, and light manufacturing. Even places with many different products can use it if you adjust the method. You do not need expensive tools to start. You just need clear rules and a promise to keep improving.

Manufacturing Environment | Applicability of One-Piece Flow |

|---|---|

Assembly Lines | Works very well for simple processes |

Electronics Manufacturing | Makes work faster and cuts waste |

Food Packaging | Helps speed and keeps production steady |

Light Manufacturing | Fits with small changes |

High-Mix, Low-Volume Environments | Can work if you adjust the flow |

Tip: You can use one piece flow at your job. Start with small changes. Work with your team. Always look for ways to make things better. Lean manufacturing means improving every day.

You will notice big changes when you use one piece flow. It helps you work faster and makes your products better. You do not need extra inventory, so you save space and money. Experts say switching between products is quicker. One piece flow works well with lean manufacturing. Look at the table below to see how it helps:

Benefit | Description |

|---|---|

Efficiency | You finish work faster and help customers sooner. |

Waste Reduction | You have less unfinished work and use less space. |

Flexibility | You can change what you make easily with less extra stock. |

Try one piece flow in your job. Your team will work better and customers will be happier.

FAQ

What is the main goal of one piece flow?

You want to move each product through every step without waiting. This helps you find problems fast. You save time and money. Your team works better together.

Can you use one piece flow outside of factories?

Yes! You can use one piece flow in offices, hospitals, or even kitchens. You move each task or item step by step. This keeps your work smooth and helps you spot mistakes early.

How does one piece flow help with quality?

You check each product right after every step. You find mistakes before they grow. This keeps your products better. Your customers get what they want.

What tools help you start one piece flow?

You can use simple tools like checklists, timers, or colored bins. Some teams use software to track progress. Start small and add more tools as you learn.

Is one piece flow hard to set up?

You may face some challenges at first. Start with small changes. Train your team. Watch your process and fix problems as they come up. You will see results soon.

See Also

Understanding Die Casting Slides And Their Importance

PPAP Uncovered: Essential For Ensuring Manufacturing Quality

The Significance Of APQP In Automotive And Aviation

Achieving Net Shape Through Effective Die Casting Techniques

Comparing Discrete And Process Manufacturing: Two Distinct Approaches

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.