Practical Advice for Selecting Measuring Tools in Quality Control

Accurate measuring instrument selection plays a vital role in manufacturing quality control. Errors in measurements can lead to costly mistakes, such as producing non-conforming parts or excessive waste.

A case study revealed that a manufacturing company faced customer complaints due to inadequate tools, resulting in defective products and dissatisfied clients.

Regular calibration ensures your instruments provide precise measurements, reducing errors and maintaining consistent quality. Calibration certificates also verify compliance with industry standards, which is essential for quality assurance. Investing in the right tools and their upkeep enhances efficiency and product reliability.

Understanding Measurement Needs

Identifying Measurement Types (Dimensional, Surface, etc.)

Understanding the type of measurement you need is the first step in selecting the right tools. Different manufacturing processes require different types of measurements, such as dimensional, surface, or geometric evaluations. Dimensional measurements focus on linear or angular dimensions, ensuring parts meet size specifications. Surface measurements, on the other hand, assess texture, roughness, or flatness, which are critical for components like seals or bearings. Geometric measurements evaluate shapes and alignments, ensuring features like holes or edges are positioned correctly.

Statistical methods often help differentiate these measurement types. For example:

ANOVA verifies the significance of factors affecting measurement errors.

Least Squares Fitting averages deviations in dimensional measurements.

Chebyshev Fitting minimizes maximum deviations in geometric measurements.

By understanding these distinctions, you can choose tools that align with your specific quality control needs.

Tip: Always match your measurement type with the appropriate equipment to avoid inaccuracies and inefficiencies.

Evaluating Part Complexity and Inspection Requirements

The complexity of a part directly impacts its inspection requirements. Simple parts with fewer features may only need basic dimensional checks. However, intricate components with tight tolerances or multiple features demand advanced inspection techniques. For instance, high-value or safety-critical parts often require Level III inspections, which are the most stringent. These inspections ensure compliance with strict quality standards and reduce the risk of defects.

When evaluating inspection needs, consider the product's importance and the potential consequences of defects. Complex parts often require tools like coordinate measuring machines (CMMs) or 3D scanners to capture detailed data. Additionally, systematic data collection methods, such as automated sensors or manual records, enhance accuracy and traceability.

Note: Investing in advanced inspection systems for complex parts can save time and prevent costly errors in the long run.

Key Factors in Measuring Instrument Selection

Instrument Quality and Precision Standards

When selecting measuring instruments, you must prioritize quality and precision. These factors directly impact your ability to maintain product standards and meet customer expectations. Precision ensures that your measurements are consistent, while accuracy reflects how closely those measurements align with the true value. Together, they form the foundation of reliable quality control.

To evaluate an instrument's quality, consider several key attributes:

Accuracy: Does the instrument provide measurements that match the true value?

Precision: Are repeated measurements consistent under the same conditions?

Repeatability: Can the instrument deliver the same results when used repeatedly?

Reproducibility: Does it perform consistently across different environments or operators?

Range and Span: Does the instrument cover the required measurement values?

Linearity: Is the output proportional to the input?

Sensitivity: How responsive is the instrument to changes in the measured variable?

Manufacturers often provide technical data derived from approved testing methods. Reviewing this data helps you assess whether an instrument meets your quality control needs. For example, coordinate measuring machines are ideal for high-precision applications, offering exceptional accuracy and repeatability. These machines are particularly useful for first article inspection, where verifying the dimensions of initial production parts is critical.

Tip: Always choose instruments that align with your precision requirements to avoid costly errors and ensure compliance with industry standards.

Calibration and Maintenance Considerations

Regular calibration and proper maintenance are essential for ensuring the accuracy of your measuring instruments. Calibration verifies that your tools provide precise readings, which is crucial for maintaining product quality and meeting regulatory requirements. It also minimizes risks in safety-critical industries, such as aerospace or pharmaceuticals, where even minor inaccuracies can have significant consequences.

Calibration practices vary across industries, but trend analysis can help you optimize calibration schedules. For instance:

Plants can analyze calibration history to determine the ideal frequency for each instrument.

Stable instruments may require less frequent calibration, reducing costs.

Critical instruments, however, benefit from more frequent calibration to ensure reliability.

The pharmaceutical sector has reported significant cost savings by adopting these practices, but all industries can benefit.

In addition to calibration, routine maintenance extends the lifespan of your instruments and ensures consistent performance. Neglecting maintenance can lead to measurement drift, which compromises the reliability of your quality control processes.

Note: Calibrated instruments not only enhance accuracy but also provide traceability to national or international standards, which is vital for audits and certifications.

Portability vs. Fixed Measurement Systems

The choice between portable and fixed measurement systems depends on your specific application needs. Portable systems, such as laser trackers and 3D scanners, offer flexibility by allowing you to take measurements directly at the workpiece location. This capability is especially valuable for large or heavy components, where moving parts to a fixed inspection area is impractical. Portable systems also enable real-time monitoring and immediate adjustments during machining processes, improving efficiency.

Fixed systems, like coordinate measuring machines, excel in high-precision environments. These systems are ideal for tasks such as first article inspection, where detailed and repeatable measurements are necessary. While fixed systems provide superior accuracy, they require a controlled environment and dedicated space, which may not suit all manufacturing setups.

When deciding between the two, consider factors such as part size, inspection location, and required precision. Portable systems are better suited for on-site testing and field applications, while fixed systems are more appropriate for controlled environments with stringent accuracy requirements.

Tip: Evaluate your workflow and inspection needs to determine whether portability or fixed systems will deliver the best results for your quality control processes.

Budget and Cost-Effectiveness Analysis

Selecting measuring instruments involves balancing quality and cost. While high-quality tools often come with a higher price tag, their long-term benefits can outweigh the initial investment. You need to evaluate whether the upfront cost aligns with your operational goals and budget constraints.

Why Higher Quality Instruments Are Worth the Investment

High-quality measuring instruments provide reliable data, which is essential for maintaining product consistency and meeting industry standards. These tools reduce the risk of errors, saving you from costly rework or customer complaints. For example, in industries like aerospace or medical manufacturing, even minor inaccuracies can lead to significant financial losses or safety concerns. Investing in precision tools ensures compliance with stringent standards and enhances your reputation for quality.

However, cheaper alternatives may seem appealing, especially for smaller budgets. While these tools can be cost-effective in certain scenarios, their accuracy and durability often fall short. If a low-cost instrument introduces measurement errors, the resulting defects can lead to higher operational costs over time. This highlights the importance of carefully assessing the trade-off between cost and quality.

Tip: Consider the long-term impact of measurement errors when evaluating cheaper tools. A higher initial investment in quality instruments can save you money in the long run.

Balancing Cost and Accuracy

When deciding between high-quality and budget-friendly tools, you should analyze the relationship between cost and measurement error. Cheaper tools can be viable if their accuracy closely matches that of premium instruments. For instance:

Short questionnaires or basic tools may suffice for less critical measurements.

If the increase in cost significantly outweighs the reduction in measurement error, a cheaper tool might be more practical.

In contrast, high-precision applications demand gold-standard instruments to ensure reliable data.

A systematic approach to cost-effectiveness analysis can help you make informed decisions. Start by identifying the critical measurements in your process. Then, compare the performance and lifespan of different tools. High-quality instruments often last longer and require less frequent replacement, which reduces overall costs.

Practical Strategies for Cost Optimization

To optimize your budget, focus on tools that meet your specific needs without unnecessary features. For example, if your process requires dimensional measurements, a micrometer or caliper may suffice instead of investing in a full coordinate measuring machine. Additionally, consider leasing high-end equipment for short-term projects to avoid large upfront costs.

Another strategy involves pooling resources. Collaborating with other departments or facilities can reduce individual expenses. Shared access to advanced tools, like 3D scanners or fixed CMMs, ensures cost-effective utilization without compromising quality.

Note: Regular calibration and maintenance also contribute to cost-effectiveness. Properly maintained instruments last longer and deliver consistent results, reducing the need for replacements.

Making the Right Choice

Ultimately, your decision should align with your operational priorities. If your process demands high precision and compliance with strict standards, investing in premium tools is essential. For less critical applications, budget-friendly alternatives can provide adequate performance. By carefully evaluating your needs and considering long-term costs, you can select instruments that balance quality and affordability.

Categories of Measuring Instruments and Their Applications

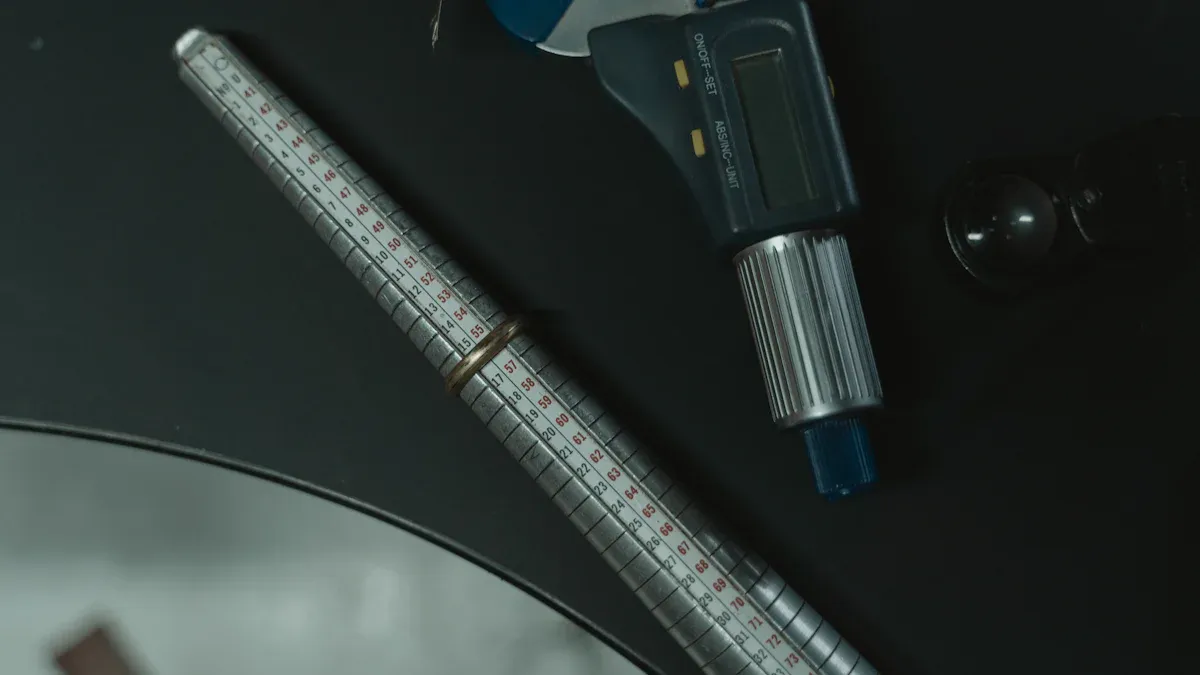

Hand Measuring Tools: Micrometers, Calipers, and Their Uses

Hand measuring tools are essential for quick and accurate measurements in quality inspection. Micrometers and calipers are two of the most commonly used tools in this category. Micrometers excel at measuring small dimensions with high precision. You can use them to measure the thickness of materials or the diameter of small parts. Calipers, on the other hand, are versatile tools that measure both internal and external dimensions. They are ideal for tasks like checking the width of a groove or the depth of a hole.

These tools are simple to use and require minimal training. Their portability makes them convenient for on-the-spot measurements. However, they are best suited for less complex parts or when high precision is not critical. For more intricate components, advanced measuring and control instruments may be necessary.

Fixed CMMs: Applications in High-Precision Manufacturing

Fixed coordinate measuring machines (CMMs) are indispensable in industries that demand high-precision measurements. These machines provide detailed and repeatable data, making them ideal for quality inspection in controlled environments. Fixed CMMs are particularly effective in industries such as automotive, aerospace, medical, and electronics.

Industry | Description |

|---|---|

Automotive | Requires high-volume inspection of parts for quality control and adherence to specifications. |

Aerospace | Demands high-precision measurements where even small defects can have significant consequences. |

Medical | Requires the highest quality and reliability standards, making CMMs critical in manufacturing. |

Electronics | Necessitates precise measurements of small and intricate components due to miniaturization. |

These machines ensure that your products meet stringent standards. They are ideal for first article inspections or verifying complex geometries. While they require a dedicated space, their accuracy and reliability make them a worthwhile investment.

Portable CMMs: Flexibility and Field Applications

Portable CMMs offer flexibility for on-site quality inspection. These measuring instruments allow you to take measurements directly at the workpiece location. This feature is especially useful for large or heavy components that are difficult to move. Portable CMMs, such as laser trackers or articulated arms, provide accurate data in real-time.

You can use portable CMMs for tasks like alignment checks or verifying dimensions during assembly. Their mobility makes them ideal for field applications or industries with dynamic workflows. While they may not match the precision of fixed systems, their convenience and adaptability make them a valuable addition to your measuring and control instruments.

3D Scanners: Measuring Complex Shapes and Surfaces

3D scanners have revolutionized the field of metrology by offering precise and efficient solutions for measuring complex shapes and surfaces. These devices use advanced technologies, such as laser triangulation or structured light, to create highly detailed 3D digitized models. You can rely on them to capture intricate geometries that traditional tools struggle to measure. Their ability to handle irregular surfaces makes them indispensable in industries like automotive, aerospace, healthcare, and construction.

In manufacturing, 3D scanners streamline the inspection process by providing accurate and repeatable measurements. For example, integrating 3D scanners with Coordinate Measuring Machines (CMMs) allows for automated inspections. This eliminates human error and ensures real-time monitoring of component dimensions. By using this combination, you can achieve consistent quality control while reducing manual intervention.

The versatility of 3D scanners extends beyond industrial applications. In healthcare, they play a crucial role in creating customized solutions. A study demonstrated that 3D scans of the human foot deliver measurements comparable to manual methods. This approach improves efficiency in designing orthopedic devices and custom footwear. It also saves time and reduces costs compared to traditional techniques.

You can also use 3D scanners to inspect parts with intricate designs or tight tolerances. Their non-contact measurement method ensures that delicate surfaces remain undamaged during inspection. This makes them ideal for inspecting fragile components or prototypes. Additionally, the ability to generate comprehensive 3D models allows you to analyze deviations and identify defects with ease.

By adopting 3D scanners, you enhance your inspection capabilities and improve overall productivity. These tools not only simplify complex measurements but also provide valuable insights for optimizing manufacturing processes.

Ensuring Measurement Accuracy in Quality Control

Operator Training and Skill Development

Operator training plays a critical role in maintaining consistency and reliability in quality control processes. When operators lack proper training, even the most advanced measuring equipment can yield inaccurate results. By investing in tailored training programs, you can ensure that your team understands the correct techniques for using metrology tools and interpreting data.

Hands-on training is particularly effective. It allows operators to practice real-world scenarios, reinforcing theoretical knowledge and improving their skills. For example, training programs designed for specific roles can address unique responsibilities, such as using CMMS for FAI inspections or performing hardness testing. Continuous education also keeps your team updated on advancements in measuring techniques and quality assurance practices.

Tip: Encourage your team to participate in workshops or certification programs. These opportunities enhance their expertise and contribute to achieving high quality standards in your processes.

Managing Environmental Factors for Accurate Measurements

Environmental conditions significantly impact measurement accuracy. Factors like temperature, humidity, and vibration can alter the performance of measuring equipment, leading to errors. For instance, temperature fluctuations can cause materials to expand or contract, affecting dimensional measurements. Similarly, vibrations from nearby machinery can disrupt sensitive instruments like CMMS.

To mitigate these issues, you should create a controlled environment for your quality control processes. Use temperature-controlled rooms for critical measurements and ensure proper insulation to minimize external vibrations. Additionally, regular monitoring of environmental conditions helps you identify and address potential risks before they affect your results.

Note: Maintaining a stable environment not only improves measurement accuracy but also extends the lifespan of your measuring equipment.

Regular Calibration and Traceability Practices

Calibration is essential for ensuring the reliability of your measuring tools. Without regular calibration, even minor deviations can compromise the accuracy of your quality control processes. Establishing a calibration hierarchy assigns traceable values to system calibrators, ensuring consistency across all measurements. This practice is especially important in industries like medical laboratories, where accurate results are critical.

Metrological traceability provides a clear chain of comparisons to national or international standards. Accredited calibration services play a vital role in maintaining this traceability. They follow established procedures and conduct proficiency testing to verify the accuracy of your instruments. Proper documentation, such as calibration certificates, further demonstrates traceability and supports compliance with quality assurance standards.

Evidence Type | Description |

|---|---|

Measurement Errors | Small measurement errors can lead to product defects and safety hazards. |

Calibration Importance | Calibration ensures the reliability of equipment used in measurement. |

Uncertainty Assessment | Quantifying measurement uncertainty maintains traceability and accuracy. |

By prioritizing calibration and traceability, you can enhance the reliability of your quality control processes. This approach minimizes risks, improves product quality, and ensures compliance with industry regulations.

Tip: Schedule regular calibration for all measuring tools and maintain detailed records. These practices not only improve accuracy but also provide valuable insights for audits and certifications.

FAQ

What is the most important factor when selecting a measuring tool?

Accuracy is the most critical factor. You need tools that provide precise measurements to ensure product quality. Always check the instrument's specifications, including accuracy, precision, and repeatability, to match your quality control needs.

How often should measuring instruments be calibrated?

Calibration frequency depends on usage, industry standards, and the instrument's stability. For critical applications, calibrate tools more frequently. Analyze calibration history to determine the ideal schedule for each instrument.

Are portable measuring tools as accurate as fixed systems?

Portable tools offer flexibility but may not match the precision of fixed systems. Use portable tools for on-site or large components. For high-precision tasks, fixed systems like CMMs are better suited.

Can I use one tool for all types of measurements?

No, different tools serve specific purposes. For example, micrometers measure small dimensions, while 3D scanners handle complex shapes. Match the tool to your measurement type for accurate results.

How can I reduce costs when investing in measuring tools?

Focus on tools that meet your specific needs. Avoid unnecessary features. Consider leasing high-end equipment for short-term projects. Sharing resources across departments can also optimize costs.

Tip: Regular maintenance extends tool lifespan, reducing replacement costs.

See Also

The Importance of QRQC in Today's Quality Management

Defining Acceptable Quality Limits in Quality Assurance

A Guide to Measurement System Analysis in Quality Control

Best Resources for Quality Management Tools and Techniques

Exploring QFD, FMEA, and DOE's Impact on Quality

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.