3 smart manufacturing robots maintenance tips for 2026

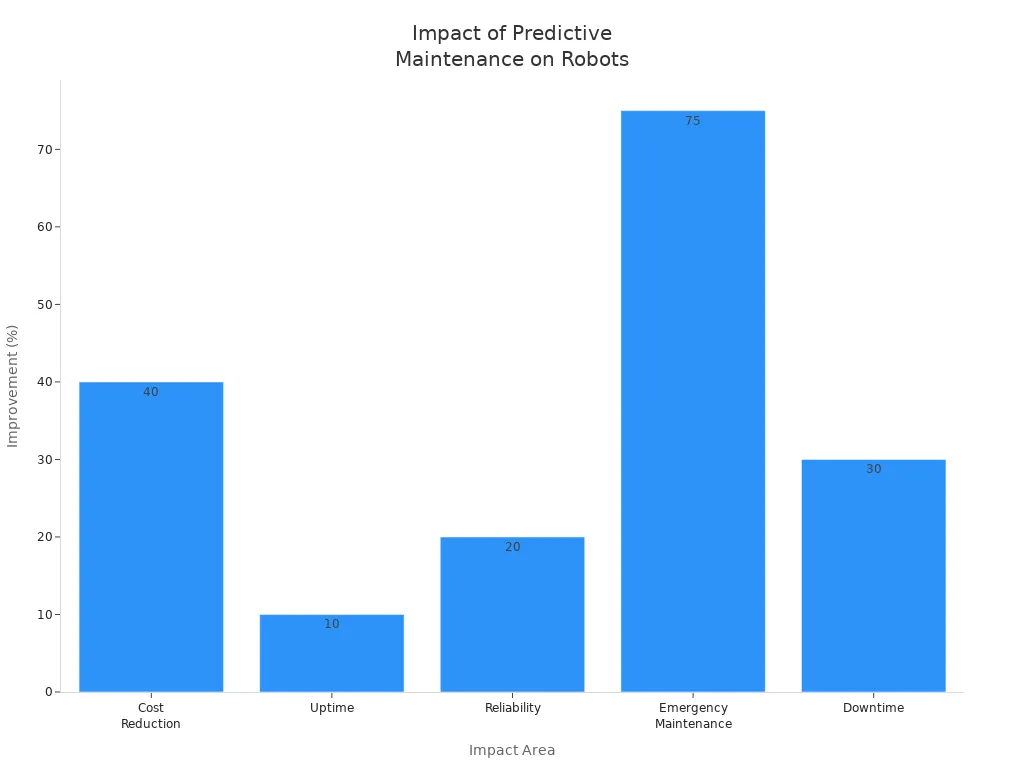

You can make manufacturing robots maintenance better by using predictive strategies, advanced sensors, and automated cloud-based systems. These methods help you keep machines working longer, save money, and make them more reliable. Companies like BMW and Siemens use AI and real-time data to keep machines working well. IoT sensors find problems early, so you do not get sudden breakdowns. The chart below shows how predictive maintenance helps a lot:

Impact Area | Evidence |

|---|---|

Cost Reduction | Predictive maintenance can lower maintenance costs by up to 40%. (Source: McKinsey) |

Uptime | Predictive maintenance can make equipment work up to 10% more. (Source: International Journal of Engineering and Technology) |

Reliability | Predictive maintenance can help machines last up to 20% longer. (Source: Frost & Sullivan) |

Emergency Maintenance | Predictive maintenance can cut emergency maintenance by up to 75%. (Source: US Department of Energy) |

Downtime | Predictive maintenance can lower unplanned downtime by up to 30%. (Source: Aberdeen Group) |

Start using these smart tools now and you will see quick results in your operation.

AI in Predictive Maintenance

Machine Learning for Failure Prediction

Machine learning helps keep robots working well. These smart systems watch sensor data and machine info. They find problems before they get worse. You can fix things early and stop big breakdowns. Here is how AI and machine learning help you spot failures:

AI checks sensor data and machine settings for trouble signs.

Machine learning looks at lots of info to find patterns and odd things.

These systems notice things like hot spots, weird shakes, or odd moves.

When AI finds something strange, it sends you a warning fast.

You can use different machine learning models to guess failures. The table below shows some common types:

Machine Learning Model Type | Application in Manufacturing Robots |

|---|---|

Non-linear classification algorithms | Connect robot actions to fault messages. |

Statistical methods | Use old plant data to guess future problems. |

Hadoop and Spark | Help check lots of data fast for predictive maintenance. |

These tools help your robots last longer and work better.

Actionable Insights from AI Analytics

AI analytics give you easy steps to make maintenance better. With AI, you can see problems early and plan repairs. This stops surprise stops and saves money. You also make your workplace safer and your products better.

Manufacturers use AI analytics to plan fixes and make smart choices. These systems watch real-time data and tell you when to act. You can plan repairs at the best time. This keeps robots working and cuts downtime. Workers can use these tips to make better choices too.

Tip: Start using predictive maintenance with AI now. You will see fewer breakdowns and save money in your factory.

Real-Time Sensor Monitoring for Manufacturing Robots Maintenance

Advanced Sensors for Data Collection

You need special sensors to keep manufacturing robots maintenance working well. Advanced sensors collect important data every second. These sensors check things like temperature, vibration, and pressure. They help you find problems before they cause damage.

Here is how each sensor helps you:

Sensor Type | Application in DBR77 System |

|---|---|

Proximity Sensor | Finds parts on belts and keeps machines safe from crashes. |

Barrier Sensor | Controls how products move and makes lines safer. |

Vibration Sensor | Spots early wear by watching machine shakes. |

Energy Meter | Checks power use to find waste and make things work better. |

Operator Declaration | Lets workers write down events that change production for better planning. |

Temperature sensors check robot parts like bearings and windings. They warn you if something gets too hot. Vibration sensors notice changes in movement. Pressure sensors watch force during production. When you use all these sensors together, you see the full health of your robots.

Tip: Sensors can find wear, overload, or failure before you see any signs. This helps you fix problems early and stop downtime.

Anomaly Detection and Instant Alerts

Real-time sensor monitoring gives you alerts right away when something is wrong. You do not have to wait for a breakdown. The system sends a warning as soon as it finds a problem. This makes manufacturing robots maintenance faster and smarter.

AI systems find broken parts before you notice anything.

IoT sensors collect data all the time and spot trouble early.

Sensors watch forces and see changes that show something is wrong.

When you get alerts fast, you can act quickly. You stop small problems from turning into big ones. Many companies have up to 40% less unplanned downtime and save 15-30% on maintenance costs. You also use your machines better, with a 20-35% boost in asset use.

Note: Real-time alerts help you fix problems 63% faster. They also make robot parts last 22% longer.

You can trust real-time sensor monitoring to keep your manufacturing robots maintenance working well. This technology works for all types of industrial robots and helps your factory run smoothly.

Automated Maintenance Scheduling and Reporting

Cloud-Based Dashboards and Workflows

Cloud-based dashboards make it simple to plan robot maintenance. These tools let you see all your robots in one spot. You can check predictive maintenance, regular tasks, and how much robots wear out. The dashboards tell you when to fix things. You do not have to guess or remember dates. The system shows you what needs to be done next.

Here is a table that lists what top dashboards can do:

Feature | KUKA iiQoT | |

|---|---|---|

Condition Monitoring | Yes | |

Asset Management | Yes | |

Predictive Maintenance | Yes | |

Fault Analysis | Yes | |

Cross-fleet Maintenance | Yes | |

Centralized Management | Yes | |

Service Management | Yes | |

Analytics & Reporting | Yes |

You can use these dashboards to control all your robots. You can see alerts, check robot health, and follow work orders. The system helps you give out jobs and check on repairs. You can use checklists and templates to follow safety rules.

Tip: Cloud-based workflows help you make fewer mistakes. You do not skip steps. You can see your data right away.

Automated scheduling helps you lower surprise downtime by up to 32%. You can watch important numbers and spot slow spots fast. You can also use smart tools to plan fixes before trouble starts.

Timely Interventions and Compliance

You need to act quickly when you get a warning. Automated systems send you alerts right away. You can fix problems before robots stop working. This keeps your factory running and robots safe.

Here is a table that shows how companies use predictive maintenance for better results:

Company | Intervention Type | Result |

|---|---|---|

Global Manufacturer | Predictive maintenance for CNC machines and robots | 40% fewer equipment failures in one year |

Power Utility | Predictive maintenance for turbines and generators | Saved $500,000 and fewer disruptions |

Frito-Lay | AI-powered predictive maintenance | Zero unexpected failures in the first year |

You can also use automatic reports to follow rules. The system keeps records and checklists. You can show inspectors you follow safety and environmental laws. You get early warnings and jobs sorted by risk. This helps you get ready for checks and avoid fines.

Feature | Benefit |

|---|---|

Keeps everyone informed and reduces confusion | |

Built-in checklists | Makes reporting easy and audit-ready |

Audit trails | Proves compliance with safety and environmental laws |

Centralized data | Shows full-plant status for better management |

Early warning detection | Cuts downtime and alerts the right teams |

Risk-prioritized workflows | Matches best practices for compliance |

Templates for compliance | Helps you follow safety rules |

Note: Automated scheduling and reports help you act on alerts, boost performance, and keep robots working longer.

You can make your factory work better with predictive maintenance, real-time sensors, and automated scheduling. These smart ways help you find problems early, save money, and keep robots working longer.

Key benefits you gain:

Stop downtime and keep machines running.

Spend less by fixing only what is needed.

Make your factory safer and your products better.

Big companies use AI and cloud systems to stay ahead. If you start now, your robots will work better and your business will grow in 2026.

FAQ

What is predictive maintenance for manufacturing robots?

Predictive maintenance uses data and smart tools to find problems before robots break. You can fix issues early. This keeps your robots working longer and saves money.

How do sensors help with robot maintenance?

Sensors check things like temperature, vibration, and pressure. They send data to your system. You get alerts when something changes. This helps you act fast and avoid breakdowns.

Why should you use cloud-based dashboards?

Cloud-based dashboards show all your robot data in one place. You can track maintenance, see alerts, and plan repairs. This makes your work easier and helps you avoid mistakes.

Can AI really reduce downtime?

Yes! AI finds problems early and tells you when to fix them. You spend less time on repairs and keep your robots running.

What are the main benefits of smart maintenance?

Benefit | How it helps you |

|---|---|

Less downtime | Robots work more hours |

Lower costs | You fix only what is needed |

Safer factory | Fewer accidents happen |

See Also

Automobile Suppliers Boost Capacity To Support Robot Manufacturing Growth

An Introductory Guide To SMED Techniques In Manufacturing

Die Casting Industry's Role In Advancing The Robotics Sector

Effective Approaches To Manage Urgent Manufacturing Requests

Improving Engineering And Manufacturing Efficiency With Quick Response Techniques

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.