What makes a manufacturer for robotics the right partner for innovative robotics startups

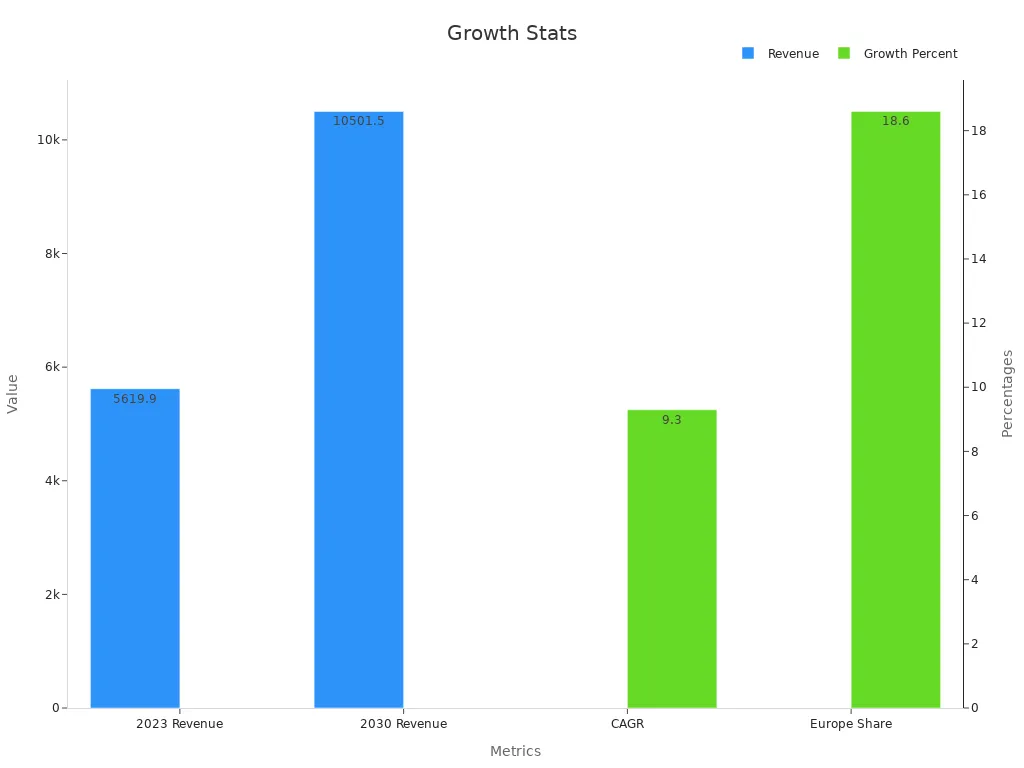

European robotics startups grow quickly and have special problems. You need parts that are light, accurate, and can do many jobs. This helps you keep up with fast changes. In 2023, the market made $5,619.9 million. It will probably grow by 9.3% each year until 2030.

Metric/Aspect | Value/Description |

|---|---|

2023 Market Revenue | USD 5,619.9 million |

CAGR (2024-2030) | 9.3% |

Projected Revenue 2030 | USD 10,501.5 million |

Europe Market Share (2023) | 18.6% of global market |

To do well, you need a manufacturer for robotics who gives:

Services for design, quality, and shipping in one package

A partnership that uses a platform and answers fast

Help for quick changes and new technology

Technical Expertise

Advanced Engineering

You need a manufacturer who really knows engineering. They must do more than just make parts. They should help with design, testing, and putting systems together. Some companies, like Boston Engineering, show what can be done. They make robots for farms, defense, and hospitals. For example, they build robots that help farmers check crops and save work. In defense, they make unmanned systems for hard jobs. In medicine, they create surgical robots that help doctors be more exact and safe.

Advanced engineering is important in projects like the Hirata Robot Simulator by AMC Bridge. This project used 3D pictures and let many robots work together in tests. It helped teams find mistakes early and try ideas before building real things. The table below lists some main features:

Aspect | Details |

|---|---|

Project | Hirata Robot Simulator by AMC Bridge |

Key Features | 3D visualization, multi-robot simulation, collision detection |

Benefits | Early error detection, cost reduction, virtual product demonstrations |

Technical Excellence | Advanced testing, user-friendly UI, deep domain research |

You want a partner who brings this kind of skill and new ideas to your work.

Rapid Prototyping

Speed is important when making new robots. Rapid prototyping lets you test ideas quickly and fix problems soon. Tools like Direct Metal Laser Sintering (DMLS) help you make test models that look and work like the real thing. This method is used in robotics, airplanes, and cars.

Modern hardware helps you move fast too. Single board computers and neuromorphic computing hardware give you quick feedback and let you change things easily. These tools help you update designs fast and grow when needed. In one study, two robots working together made models faster and better than one robot. This shows how good tools and teamwork can help you make better prototypes.

Tip: Pick a manufacturer who gives both advanced engineering and rapid prototyping. This helps you stay ahead in the fast-changing robotics field.

Scalable Production

Small-Batch to Mass Production

You need a manufacturer who can grow with you. At first, you might only need a few parts for tests. Later, you could need thousands for full production. A good partner helps you move from small batches to mass production. You do not want delays or extra costs.

The Smart Cobots Assembly Cell (SCAC) at the University of South Australia is a good example. Their robotic assembly cell can make one part at a time or many in a row. The robots do not need to stop or get new programs. This lets you try new ideas and then make more parts fast when you are ready.

Here is how automated systems and manual work compare:

Metric | Manual Operation | Automated System | Improvement (%) |

|---|---|---|---|

Production Speed | 20-30 parts/hr | 90-120 parts/hr | Up to 350% |

Labor Cost | $40/hr | $15/hr | 62.5% reduction |

Setup Time | 30-45 minutes | 5-10 minutes | 83% reduction |

Scrap Rate | 8% | 2% | 75% reduction |

You can see that automation makes things faster and cheaper. It also helps you make better products. This flexibility helps you keep up as your startup grows.

Agile Supply Chain

You also need a supply chain that can change quickly. An agile supply chain uses smart tools and teamwork to keep things running well, even when things change fast.

BMW uses collaborative robots to make assembly faster by 30%. Workers and robots work together safely.

Bosch Rexroth’s flexible automation system makes changeover times 41% shorter. You can switch products quickly.

GE Healthcare uses real-time analytics to cut unplanned downtime by 21%. Machines get fixed before they break.

Siemens uses digital twins to make productivity 25% better. Virtual models help plan and fix problems before they happen.

Intel’s feedback loops help new processes become stable 22% faster. You get good results sooner.

Agile supply chains use sensors, artificial intelligence, and cloud computing. These tools help you see what is happening right now and make smart choices. You can fill new orders, fix problems fast, and keep your startup moving forward.

Quality and Compliance

Testing and Validation

You want your robotics parts to be safe and work well. Testing and validation help make this happen. Manufacturers check quality in many steps. First, they look at raw materials before making anything. They make sure these materials are good enough. While making parts, they check for problems right away. Before sending parts out, they do a last check. This makes sure every part is safe and meets quality rules.

Modern factories use special inspection systems. These systems have AI-powered cameras and inspection robots. These tools find small problems that people might not see. They also save records of every check. This helps with audits and proves you follow the rules.

Manufacturers use different ways to test. They use computer simulations, real-life tests, and official checks. For example, they use probabilistic model checking to see how robots act in many cases. They also use simulation-based testing and real tests. This makes sure robots work the way they should. This way, you know your products are safe and reliable.

The National Institute of Standards and Technology (NIST) made test boards and rules for robots. These tests use math to see how well robots grab and move things. You get results that are clear and can be repeated. This shows your robots meet industry standards.

Key Quality Metrics in Robotics Manufacturing:

Overall Equipment Effectiveness (OEE): Checks how well machines work.

Quality Defect Rate: Counts how often problems happen.

Compliance with ISO 9001 and IATF 16949: Proves strong quality management.

Standards and Certifications

You need to know your manufacturer follows strict rules. International standards set the level for safety, performance, and quality. ISO 10218-1 is about design and safety for industrial robots. ANSI/RIA R15.06 matches these rules for safety at work. ISO 9001 is for quality management. ISO 14001 is for green manufacturing.

Safety marks like CE in Europe and UL in the US show robots meet tough safety laws. These certifications help you sell robots in more places. They also help customers trust your products.

Key Standards and Certifications:

ISO 10218 and ANSI/RIA R15.06 for safety

ISO 9283 for performance

ISO 14001 for environmental management

ISO 9001 for quality management

Studies from the International Federation of Robotics and NIST show that following these standards means fewer accidents, better products, and more chances to sell. When you pick a manufacturer with these certifications, your startup has a better chance to do well.

Collaboration Platform

A strong collaboration platform makes the best manufacturer for robotics stand out. You need more than a supplier. You need a partner who helps you at every step. This is very important for European small and medium-sized robotics companies. A factory-external cooperation platform puts all the services you need in one place. This makes your work easier and helps your startup grow faster.

Packaged Services

A manufacturer for robotics should give you a full set of services. These services cover design support and technical help. When you get all these services together, you save time and make fewer mistakes.

Key packaged services include:

Design support

Post-processing

Quality inspection

Logistics

Data services

Technical support

Using packaged services gives you many good things:

Logistics robots with IoT and real-time data make your supply chain smarter and faster.

AI and IoT help with predictive maintenance and inventory, so you avoid delays.

Robotics-as-a-Service (RaaS) lets you use robots without buying them. You pay only for what you use.

Consulting, training, and support help you use new robots quickly and safely.

Robots make workplaces safer and lower mistakes in packaging and shipping.

A good manufacturer for robotics also helps you with quality. For example, advanced process control (APC) can lower defects by over 30%. Production yields can get better by up to 45%. Scrap and rework go down, which saves money. Companies that use AI-powered inspection systems can find 98% of defects. This means fewer returns and happier customers.

You see these benefits in many industries:

Automotive companies use robots for welding and inspection.

Electronics makers use robots for assembly and soldering.

Food and beverage companies use robots for packaging and sorting.

A table below shows how packaged services help:

Service Area | Benefit |

|---|---|

Design Support | Faster product development |

Post-Processing | Higher quality and fewer defects |

Quality Inspection | Fewer returns and warranty claims |

Logistics | Faster shipping and better tracking |

Data Services | Smarter planning and forecasting |

Technical Support | Quick problem-solving and training |

Responsive Support

You need a partner who answers fast and changes with your needs. Robotics startups often face quick changes. Your manufacturer for robotics should keep up with you. They should give support that learns and gets better over time.

Modern manufacturers use smart software that changes with feedback. For example, they test different learning rates to find the best balance between speed and stability. This means the system can change quickly when you give new feedback, but it also stays steady even if there are mistakes. The software can work differently for different users, like engineers or operators. This helps you get the right support for your team.

Tip: Pick a manufacturer who can change with you. Look for one who gives fast answers, updates their services, and learns from your feedback.

Responsive support also means you get help when you need it. If you have a problem, you can ask and get a quick answer. If your needs change, your partner can change their services. This kind of support helps you stay ahead in a fast-moving market.

A collaboration platform with packaged services and responsive support gives you a strong base. You can focus on building great robots while your partner takes care of the rest.

Choosing a Manufacturer for Robotics

Innovation Support

When picking a manufacturer for robotics, find one that helps you be creative. The best partners do more than just make parts. They help you try out new ideas and get feedback. This helps you make your products better. You can join online groups to share ideas and learn from others. Some manufacturers set up workshops. In these, you and other startups work together and solve problems.

You should also see if your partner gives extra help. This can mean getting advice, finding money, or meeting more people in robotics. A strong manufacturer for robotics helps you build robots that fix real problems. They want you to use beta testing and prototyping. This makes sure your robot works for customers. They might even help you plan to grow and meet investors who know robotics.

Here are some ways manufacturers help with new ideas:

They ask customers what they need with surveys.

They use beta testing to get feedback on new robots.

They make online groups for sharing ideas.

They hold workshops to solve problems together.

A good partner helps you stay ready for changes as technology grows.

Track Record with Startups

You want a manufacturer for robotics who has helped startups before. Look for partners who have helped other companies do well. You can use clear numbers to compare different manufacturers. These numbers include time, cost, quality, safety, and how much work gets done. Some companies use stories and interviews to show how they helped startups reach their goals.

The table below shows examples of manufacturers and investors who have helped robotics startups:

Manufacturer / Investor | Robotics Startup / Deployment | Investment / Outcome | Impact / Result |

|---|---|---|---|

O’Reilly AlphaTech Ventures (OATV) | Fetch Robotics, 3D Robotics, Planet Labs | $250,000 to $2 million in early-stage funding | Early-stage investment in robotics startups |

ABB | Industrial robot deployments | N/A | 30% higher productivity at Apotea (online pharmacy) |

Fanuc | Industrial robots at Royal Dutch Shell | N/A | Increased productivity in solar cell manufacturing |

Hitachi | Robotic automation from ABB | N/A | 400% production boost in powdered metals |

Kawasaki Heavy Industries | End-of-line processing automation | N/A | Improved operational efficiency at Westheimer Brewery |

Universal Robots | Collaborative robots (UR3, UR5, UR10) | N/A | Automated engine oil filling at Ford; quality and productivity gains at Beyerdynamic and others |

You can see that the right manufacturer for robotics brings real results. They help startups work better, save money, and find new markets. When you pick a partner with a good history, your startup has a better chance to win.

You need a manufacturer for robotics who offers more than just parts. Look for a partner with strong technical skills, packaged services, and a platform for easy teamwork. Use this checklist:

Do they support design and rapid changes?

Can they scale production?

Do they offer quality checks and certifications?

Is their support fast and flexible?

Choose a partner who helps you grow and adapt.

FAQ

What should you look for in a robotics manufacturer?

You need to check if they have good technical skills. They should give you packaged services and help your team work together. Make sure they can make more parts when you need them. They should answer your questions fast. Look for strong quality checks and important certifications.

How can a manufacturer help you with rapid changes?

A good manufacturer uses smart tools and flexible systems. You can try new ideas fast and get feedback quickly. This helps you keep up when the market changes.

Why do certifications matter for your robotics startup?

Certifications show your manufacturer follows safety and quality rules. You can trust their parts are safe. These marks also help you sell robots in more places.

What are packaged services in robotics manufacturing?

Packaged services give you design help, post-processing, quality checks, logistics, data, and technical support. You get all these things in one place. This saves you time and helps you make fewer mistakes.

See Also

How To Collaborate Successfully With An Overseas Diecast Factory

Understanding APQP And Its Importance In Automotive Aviation

Boosting Engineering And Manufacturing Efficiency Through Quick Response

Comparing Cost Benefits Of Plastic Versus Aluminum Prototypes

A Supplier’s Guide To Sustainable Casting Using CBAM Principles

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.