Understanding Jidoka Meaning and Principles in Lean Manufacturing

Jidoka meaning refers to a principle in lean manufacturing that allows machines or workers to stop work if they identify a problem. This concept of Jidoka helps companies ensure high-quality products at every stage of production. By implementing this method, lean ideas are supported through increased efficiency and maintained product quality. Reports indicate that Jidoka cuts mistakes by 60%, boosts production by 20%, and saves 10-15% on costs associated with fixing and discarding defective items. Additionally, the process results in over 400 hours saved for each defect identified.

Metric | Result |

|---|---|

Reduction in defect rates | 60% |

Increase in throughput | 20% |

Savings in rework and scrap | 10-15% |

Manhour savings per defect | Over 400 manhours |

Key Takeaways

Jidoka lets machines and workers stop work if there is a problem. This helps make sure products are good quality.

Using Jidoka can lower mistakes by 60%. It can also make work faster by 20%.

The idea focuses on teamwork between machines and people. It helps find problems fast and fix them quickly.

Jidoka uses continuous improvement (kaizen) by asking all workers to spot and solve problems. This makes everything better.

Jidoka saves a lot of money and helps work run well. It stops mistakes before they get worse.

Jidoka Meaning

Definition

Jidoka meaning is about making sure quality is checked at every step. In Lean manufacturing, jidoka means adding automatic quality checks to the process. Machines and people can stop the line if they see a problem. This stops bad products from moving forward. Jidoka lets machines and workers spot problems and stop work fast. This helps keep quality high at each step. Some people call this "autonomation" or "intelligent automation." Jidoka lets machines and people find problems and stop work right away. This way, problems are fixed early, not at the end.

Automation with a Human Touch

Jidoka meaning is more than just using machines. Normal automation is about speed and doing the same thing over and over. It may keep running even if there are mistakes. Jidoka adds smart thinking to machines. Machines and people react fast when something is wrong. The system stops right away if it finds a problem. This helps people fix things quickly. Technology and people working together makes things safer and better. People watch over the machines and check their work. If a machine finds a problem, a person can look and decide what to do. This teamwork stops mistakes and keeps things running. Jidoka meaning shows why people need to check for errors early. Finding mistakes early keeps things running well and products good.

Note: Jidoka puts quality checks in the process, not just at the end. This helps stop problems before they get worse and makes results better.

Benefit | Description |

|---|---|

Integration of technology and human operators | Jidoka lets machines and people work together, making work better. |

Prevention of defects | The system stops work to keep bad parts from moving on. |

Continuous improvement | Jidoka helps everyone learn and get better by finding and fixing problems. |

Operational excellence | It uses resources well, keeps people safe, saves money, and helps the company do its best. |

Jidoka in the Toyota Production System

Jidoka Philosophy

Toyota uses jidoka to make sure every step has quality. Machines and people work together to find problems early. Each machine can spot mistakes and tell someone. Workers can stop production if they see something wrong. This stops bad parts from moving forward. Teams can fix problems fast.

Core Element | Description |

|---|---|

Detect anomalies | All equipment must find mistakes and tell someone. |

Stop production | Machines stop by themselves, and workers can stop them too. |

Correcting the urgent problem | Workers look at the problem and ask for help after stopping. |

Jidoka makes quality part of the process, not just at the end. Machines stop when they find a problem. Workers can stop the line too. This teamwork helps everyone get better and use kaizen. Jidoka helps workers feel trusted and respected. They do more than follow orders. They help fix problems and improve the process.

Tip: Jidoka helps teams fix problems fast, so they save time and materials.

Role in Quality Control

Jidoka is important for quality control at Toyota. Workers can stop production if they see a mistake. This keeps bad parts away from customers. Toyota uses jidoka to build quality into every step. Teams do not wait until the end to check for mistakes. They use kaizen to make things better every day.

Jidoka lets workers stop production when they see a problem.

Machines and people work together to find mistakes early.

The system helps teamwork and problem-solving with kaizen.

Jidoka started with Sakichi Toyoda’s loom that stopped when a thread broke. This idea changed how factories worked. Workers could focus on making things better, not just watching machines. Today, Toyota uses jidoka everywhere. The company is known for quality because it stops problems early and uses kaizen to improve.

Principles of Jidoka

Detecting Defects

Jidoka starts with finding defects right away. Machines and operators work together to spot problems early. Special technology helps find defects fast. AI-powered computer vision systems check surfaces in real time. Bio-inspired sensors notice brightness changes to catch defects. 3D machine vision systems use lasers to measure depth and find flaws. Neural networks and transformer models sort defects very well, sometimes over 99% correct. These tools help companies keep quality high and waste low.

Technology/Method | Description |

|---|---|

AI-powered computer vision systems | Finds surface defects quickly, lowers waste, and keeps machines running. |

Bio-inspired vision sensors | Notice brightness changes for better defect spotting. |

3D machine vision systems | Use lasers and light to measure depth and find flaws. |

Advanced neural networks (e.g., YOLOv11) | Spot defects with high accuracy, up to 93.4%. |

Transformer models | Use smart imaging to sort defects with over 99% accuracy. |

Anomaly detection methods | Learn with little labeled data to find defects well. |

Event-based cameras | Good at finding weak defects using energy difference. |

Attention-guided fusion networks | Mix features from different scales to spot defects better. |

Operators are important too. They watch for problems and use their skills to find defects that machines miss. Keeping machines calibrated helps find defects, so regular checks matter. Finding problems early stops them from spreading and helps teams get better.

Stopping the Process

When a defect is found, jidoka says to stop right away. This is called "stop and fix." Operators can stop production if they see a problem. Machines can stop themselves too. This keeps bad products from moving forward and keeps quality high.

Tip: Letting workers stop and fix problems builds trust.

Some reasons to stop the process are:

Operators see something wrong.

Machines find a defect.

Emergencies need someone to step in.

Stopping shows where the defect is and lets teams fix it fast. This saves time and resources by stopping more damage.

Response and Correction

After stopping, the team must fix the problem. Jidoka follows these steps:

Stop the process.

Check what caused the defect. The team looks for operator mistakes or machine problems.

Fix the defect right away. Make changes to solve the issue.

Start production again only when the problem is gone.

Operators use error-proofing like poka-yoke to stop mistakes from happening again. Training and standard steps help everyone find and fix defects faster. This way, quality is built into every part and teams keep improving.

Evidence Description | Statistical Value |

|---|---|

Relationship between M&E and ES in H5 | |

Importance of calibrated machines in defect detection | Strong link shown |

Prevention and Kaizen

Jidoka does not just fix defects. The last step is prevention and kaizen, which means always getting better. Teams work together to stop the same defect from happening again. Kaizen asks everyone to look for small ways to improve. This helps companies cut waste and make quality better.

Kaizen includes all workers in making things better. Workers share ideas, find problems, and suggest changes. Lean manufacturing uses kaizen to find defects early and make products better. Jidoka and kaizen together help companies fix problems fast and keep them from coming back.

Note: Jidoka and kaizen work together to build quality and help teams improve all the time.

Jidoka works with other Lean Manufacturing methods, like automatic defect finding, human checks, and stopping defects.

Tools such as poka-yoke and Andon systems help connect jidoka to Lean practices.

The four steps—finding, stopping, fixing, and preventing—work together to make processes better and keep improving.

Applying Jidoka

Real-World Implementation

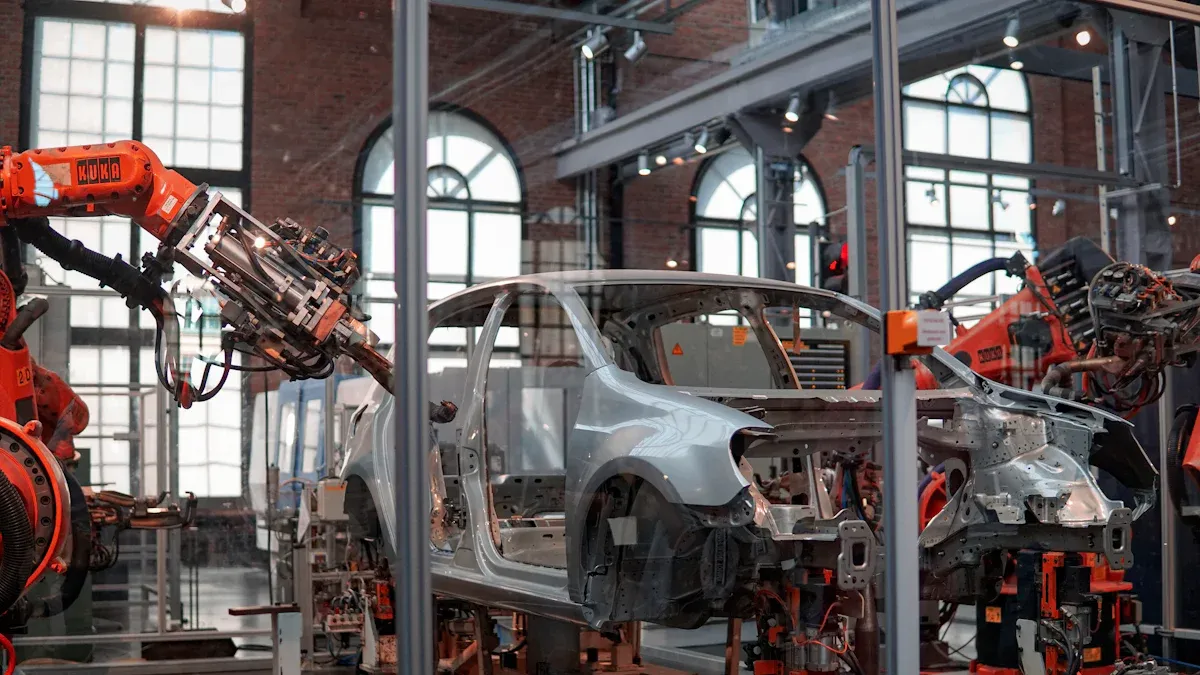

Manufacturing companies use jidoka to keep quality high. Toyota mixes machines and human checks in their system. Machines can stop by themselves when they find a problem. Operators fix the issue before work starts again. This stops defects from moving forward. Many companies use these steps for jidoka:

Put in sensors and monitors to spot problems.

Let operators fix faults quickly.

Check data and improve workflows all the time.

Companies see many good things from jidoka. They work faster and solve problems quickly. Products are better and have fewer mistakes. The table below shows some results:

Benefit Description |

|---|

Faster office work and fewer delays in processes. |

Saves money and shows results before big spending. |

Operations last longer and match company responsibility goals. |

Quicker problem-solving with less risk in real work. |

Stops making too much when demand drops or not enough when demand rises. |

Supply chains can fix themselves and handle changes. |

Leaders learn about risks early and can fix them fast. |

Workers learn more and help solve problems right away. |

Products are better, with fewer mistakes after launch and happier customers. |

More people support changes and Lean ideas face less pushback. |

Common Challenges

Some factories have trouble using jidoka. Old plants do not like stopping work, so workers cannot act fast. Teams must know which problems are big or small, or they waste time. Workers may not use Andon systems because they worry about blame or looking slow.

To fix these problems, companies use smart ways. They start with good data and use AI to find rare problems. Cameras and lights are set up the same way for better checks. Edge AI links to controls for quick action. Teams update models with new data to keep up with changes.

Challenge | Best Practice |

|---|---|

Good labeled data is needed | Begin with balanced data, then use AI to spot rare problems. |

Different lights or camera spots | Set up cameras and lights the same way every time. |

Adding to real-time work | Use edge AI systems that connect to controls for fast actions. |

Changing work areas | Keep updating models with new data to match changes. |

Principle of Kaizen Jidoka

Kaizen jidoka means always getting better. Jidoka helps teams find problems early and stop work. Operators fix the fault and look for the main cause. This way, everyone helps make things better. Workers feel good when they help solve problems. Their ideas bring new ways and better teamwork. Jidoka lets teams act, so they keep improving. Companies get better quality, more work done, and stronger operations. Jidoka also helps more people support changes and lowers mistakes after launch.

Tip: Jidoka and always improving help everyone do their best at work.

Jidoka is an important idea in Lean Manufacturing. Toyota uses jidoka to make sure every step has good quality. Operators and machines work together as a team. The table below shows how jidoka helps Toyota see problems, work faster, and save money.

Benefit | Description |

|---|---|

Improves Visibility | Jidoka helps everyone see problems right away, so they can fix them fast. |

Boosts Productivity | Finding defects early stops bigger problems and helps work go faster. |

Reduces Waste | Stopping work when there is a problem saves materials and resources. |

Lowers Costs and Downtime | Fixing problems early means spending less money and having fewer stops. |

Enhances Product Quality | Checking quality during work makes sure products are good and customers are happy. |

Empowers Operators | Operators are trusted to watch for quality, so they help make things better all the time. |

Improves Production Processes | Looking for the main reason for problems helps make work better for a long time. |

Toyota tells teams to stop work if they find a problem. They use sensors and machines that can stop by themselves. Workers feel trusted to act quickly and fix things. Some people think stopping machines is hard, but Toyota teaches workers how to do it well. Jidoka is not just for factories. Hospitals use machines to watch patients, and banks use systems to catch mistakes. When leaders use jidoka, teams get better every day and keep quality high.

FAQ

What does jidoka mean in lean manufacturing?

Jidoka means stopping work when a problem is found. Workers and machines look for mistakes. This helps teams keep quality good. Lean companies use jidoka to fix problems early. This stops defects from moving to the next step.

How does jidoka help detect anomalies?

Jidoka uses sensors and smart tools to find problems. Operators watch for changes in how things work. Machines stop if they see something wrong. Lean teams fix issues fast and keep products safe.

Why do lean companies stop the process for defects?

Stopping work helps workers fix defects right away. Lean methods teach teams to act quickly. This keeps bad parts out of later steps. Companies save time and money by solving problems early.

Can lean principles work with old machines?

Lean ideas work with both new and old machines. Teams add sensors or simple checks to older equipment. Operators watch for problems and stop work if needed. Lean helps every factory make quality better.

How does lean support continuous improvement?

Lean helps teams get better by finding and fixing problems. Teams use jidoka to spot defects and issues. Workers share ideas to improve each step. Lean companies grow stronger by learning every day.

See Also

Understanding The Fundamental Concepts Behind Lean Manufacturing

A Simple Guide To Jigs And Fixtures In Manufacturing

Decoding TIMWOOD: Its Meaning In Lean Manufacturing

The Importance Of SMED In Modern Lean Manufacturing

An Easy Explanation Of Subtractive Manufacturing For All

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.