Top Tips for High-Speed Cutting Safety

High-speed cutting needs you to focus on safety. Fast-moving tools can cause bad accidents if rules are ignored. Broken tools or skipping safety steps make injuries more likely. Being safe keeps you protected and helps work go smoothly. Always use the correct tools, wear safety gear, and follow the rules. Safety isn’t just a rule—it’s your job to keep work safe and successful.

Understanding the Risks in High-Speed Cutting

Hazards of Improper Tool Use

Using tools the wrong way can cause accidents. Learn how each tool works and use it properly. For example, 20% of workdays lost happen due to unsafe tool use. Most accidents (60%) occur while machines are running.

Machinery Type | |

|---|---|

General Machines | 2 |

Production Machines | 1.31 |

Flexible Systems | 0.82 |

These numbers show why using tools correctly is important. Always follow instructions and avoid risky shortcuts.

Risks of Damaged or Flawed Abrasive Wheels

Broken abrasive wheels are very dangerous. Angle grinders with these wheels cause over 5,000 injuries every year. Half of these injuries happen because of unsafe work habits or mistakes. The Royal Society for the Prevention of Accidents says angle grinders are the third most dangerous tool, causing 5,400 injuries yearly.

Check abrasive wheels often for cracks or damage. Replace broken wheels right away to stay safe. Follow safety rules for cut-off wheels to avoid injuries.

Consequences of Neglecting Safety Protocols

Skipping safety steps can lead to serious problems. High-speed cutting makes loud noise that can hurt your ears. Studies show 31% of wood product workers and 44% of wood manufacturers lose hearing from noise over 85 dB. Loud noise also makes it harder to focus and talk, which can cause more accidents.

Ignoring safety doesn’t just hurt you—it affects your team and workplace. Always wear safety gear, follow rules, and keep tools in good shape. These steps protect everyone and keep work running smoothly.

Best Practices for High-Speed Cutting Safety

Proper Use and Maintenance of Tools

Using tools the right way is very important. Always check tools before starting work. Look for damage, loose parts, or wear. Follow the maker’s guide to keep tools in good shape. This helps avoid accidents and keeps tools working well.

Why proper tool use and care matter:

Tools last longer and work better.

Good designs lower tiredness and prevent injuries.

Regular care stops problems like "white-finger" disease.

Safe tools mean fewer accidents while working.

Never use tools for the wrong job. For instance, don’t use a cut-off wheel to grind. This can break the tool and cause harm. Always follow safety rules for cut-off wheels.

Tip: Make a schedule to check and fix your tools. This keeps them safe and ready to use.

Importance of Personal Protective Equipment (PPE)

Wearing personal protective equipment (PPE) is key to staying safe. Safety glasses, gloves, and ear protection guard you from dangers like flying bits, loud sounds, and sharp edges. Without PPE, you’re more likely to get hurt.

Statistic Description | Value |

|---|---|

Workers not wearing PPE during accidents | |

Odds of being safer with PPE | 0.2 (95% CI, 0.1-0.4) |

Workers with at least one accident | 84.9% |

Workers hurt in the last year | 64.3% |

Common injuries: Cuts | 51.8% |

Common injuries: Lacerations | 51.0% |

Common injuries: Eye injuries | 46.2% |

PPE lowers the chance of getting hurt. Safety glasses protect your eyes from flying pieces. Gloves stop cuts and scrapes. Ear protection saves your hearing from loud noise.

Note: Check your PPE for damage before using it. Replace broken gear to stay safe.

Regular Inspection and Calibration of Equipment

Checking and adjusting tools often keeps them safe to use. Look for cracks, loose parts, or other problems. Fix issues before they get worse. Adjusting tools makes sure they work correctly and safely.

Why checks and adjustments are important:

They stop tools from breaking during use.

Custom care plans make tools safer and better.

Take time to inspect tools often. Look for damage and test how they work. Fix any problems right away. Adjust tools as the maker suggests to keep them accurate.

Tip: Write down when you check and adjust tools. This helps you remember and follow safety rules.

Common Prohibited Practices to Avoid

Using Non-Standard Attachments

Using attachments not made for your tool is unsafe. These parts are not tested for safety and can cause accidents. For example, using a blade not recommended by the maker can make the tool shake or break. This increases the chance of injuries.

Always use attachments listed in the tool's manual. These are made to work safely with your tool. If unsure about an attachment, ask the maker or a professional. Never try non-standard parts, as they can harm you and damage the tool.

Tip: Make a list of approved attachments for each tool. This helps you use the right parts every time.

Misusing Cut-Off Wheels for Grinding

Cut-off wheels are for cutting only, not grinding. Using them to grind can be very dangerous. Grinding puts different forces on the wheel than cutting does. Studies show these forces are hard to predict, making accidents more likely. The wheel might break or shatter under stress.

Grinding with a cut-off wheel also wears it unevenly. This makes it weaker and more likely to break. Flying pieces can hurt you or others nearby. Always pick the right wheel for the job. Use a grinding wheel if you need to grind.

Note: Check your cut-off wheels often for damage. Replace them if they are worn or cracked.

Performing Inverted Cutting

Inverted cutting means using the tool upside down or at a bad angle. This makes it harder to control the tool and stay safe. It can cause kickback, where the tool jerks suddenly and might hurt you.

Inverted cutting also sends sparks and debris in random directions. This makes it harder to protect yourself, even with safety gear. Always hold the tool the right way and stand firmly. Using proper techniques keeps you safe and improves your work.

Reminder: Set up your workspace neatly and securely. A clean area helps you avoid unsafe methods like inverted cutting.

Advanced Safety Tips for High-Speed Cutting

Adjusting Techniques for Different Materials

Different materials need special cutting methods for safety. Softer materials like wood need slower speeds. Harder materials like steel need faster speeds and special tools. Changing your method lowers tool damage and gives cleaner cuts.

Studies show cutting methods should match material types. A cutting force model changes with different conditions. This shows how materials affect cutting. Tool runout also changes, showing why precision is important.

Key Findings | Description |

|---|---|

Cutting Force Model | Matches material type for safe, efficient cutting. |

Tool Runout Effect | Shows why precision matters for each material. |

Cutting States | Explains states like normal or cross-flute based on material. |

Tip: Test your cutting method on a small piece first.

Managing Heat and Friction

Heat and friction happen during high-speed cutting. Controlling them keeps tools safe and lasting longer. Too much heat weakens tools. Friction wears them out faster. Cooling methods like cryogenic cooling or lubrication help reduce these problems.

Research shows cryogenic cooling lowers cutting forces and tool wear. Lubrication makes tools last 30% longer and improves the cut's finish. These methods make cutting safer and smoother.

Technique | Impact on Tool Longevity | Impact on Safety |

|---|---|---|

Cryogenic Cooling | Less tool wear | Lower cutting forces |

Lubrication Techniques | Tools last 30% longer | Better surface finish |

Note: Clean tools often to remove dust, which causes heat and friction.

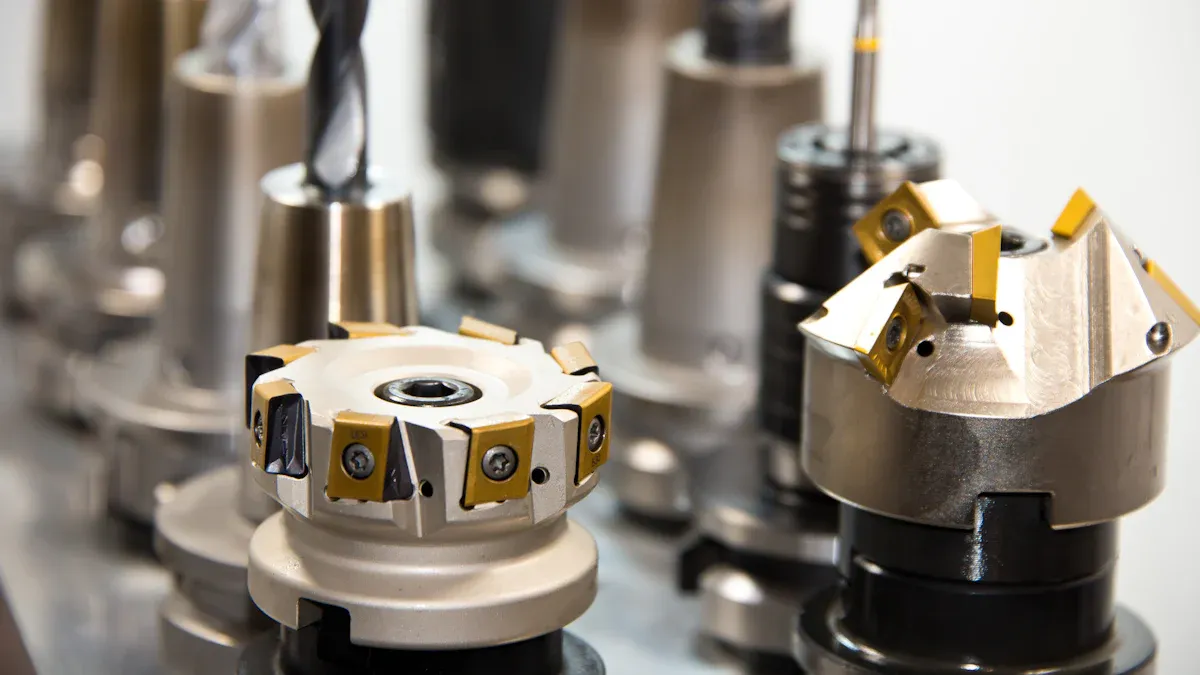

Selecting Specialized Tools for Specific Tasks

Using the right tool for each job is very important. Special tools are made for certain materials and tasks. This lowers accident risks. For example, carbide tools with TiAlN coatings work well for fast cutting. PCD tools are best for soft metals.

Data shows tools with high wear resistance last longer. They stay strong even at high temperatures. This makes them great for cutting hard metals or paving materials.

Tool Type | Benefit Description |

|---|---|

High Wear Resistance | Tools last longer when cutting tough materials. |

Carbide and Coated Carbide | Coatings lower friction and handle heat better. |

Polycrystalline Diamond (PCD) | Great for soft metals and gives smooth finishes. |

Thermal Stability | Stays strong in heat, perfect for fast cutting. |

Reminder: Always secure your material tightly before cutting for safety and accuracy.

Regulatory and Industry Guidelines for Safe Cutting

OSHA Standards for High-Speed Cutting

OSHA makes rules to keep you safe while cutting fast. They focus on stopping exposure to silica dust, which is harmful. Breathing silica dust can cause lung disease or cancer. OSHA says to use ventilation systems to lower silica dust in the air.

You also need to wear PPE like respirators when cutting materials that make silica dust. OSHA requires training to teach workers about silica dangers and safety steps. These rules help protect your health and prevent injuries at work.

Tip: Look for silica dust in your workspace often. Clean it up to stay safe and follow OSHA rules.

Manufacturer Recommendations for Tool Use

Tool makers give advice to help you use tools safely. They explain tool shapes, coatings, and which materials they work with. For example, ceramic tools handle heat well but break easily on soft metals. Diamond-coated tools last long but don’t work well on steel.

Tool Type | Advantages | Disadvantages |

|---|---|---|

Ceramic Tools | Handles heat, great for hard stuff | Breaks easily on soft metals |

Cermets and CBN | Lasts long, good for hard finishes | Costly, limited uses |

Diamond-Coated Tools | Very durable, smooth finish | Not for steel, expensive |

Tool Geometry | Lowers vibration, lasts longer | N/A |

Advanced Coatings | Tools last longer, better finishes | N/A |

Follow the maker’s instructions to use tools correctly and safely. Always read the manual and don’t guess how to use tools.

Staying Updated on Industry Best Practices

Learning new safety tips helps you stay safe while cutting. Updates on tools, cutting methods, and silica safety make work better and safer. Groups share advice on lowering silica dust and avoiding lung diseases.

Go to workshops to learn about new safety ideas. Talk to others in your field to find better ways to cut and stay safe. Keeping up with new ideas protects your health and improves your skills.

Reminder: Sign up for newsletters and follow trusted groups to learn the latest safety tips.

FAQ

How should you safely use a cut-off wheel?

Use cut-off wheels only for cutting jobs. Never grind or push sideways. Check for cracks or damage before using. Secure your material tightly and wear safety gear. Follow the maker’s rules for speed and use.

How often should tools and wheels be checked?

Check tools and wheels every time before using them. Look for cracks, worn spots, or loose parts. Replace broken wheels right away. Regular checks keep you safe and stop accidents. Use a schedule to track repairs and inspections.

Can cut-off wheels work on all materials?

No, cut-off wheels are made for certain materials. Use wheels meant for metal, wood, or concrete. Using the wrong wheel can break it or cause harm. Always read the maker’s guide for safe use.

Why is wearing PPE important for cutting?

PPE keeps you safe from flying bits, sparks, and loud sounds. Glasses protect your eyes, gloves stop cuts, and ear covers save your hearing. Without PPE, you could get badly hurt. Check your gear for damage before using it.

What should you do if a wheel breaks?

Stop right away if a wheel breaks. Turn off the tool and check for damage. Replace the broken wheel with a new one. Inspect the tool for problems before starting again. Never use a damaged wheel.

See Also

Exploring Various Categories of CNC Cutting Tools Available

Ten Strategies to Improve Route Cards in Production

Ten Key Surface Finishing Techniques for Metalworking

How Cutting Dies Enhance Efficiency in Manufacturing Processes

The Impact of Quick Response Methods on Manufacturing Efficiency

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.