Efficient Strategies for Handling Urgent Manufacturing Orders

You can handle an urgent manufacturing order well by acting fast and setting clear priorities. Find out quickly if equipment works, if staff are trained, and if the supply chain is strong. This helps keep production moving fast. Look at the most common problems below:

Challenge | Description |

|---|---|

Equipment Reliability | Regular checks stop machines from breaking during urgent orders. |

Staff Training | Training workers in many jobs helps them adjust to new needs. |

Supply Chain Management | Good supplier connections help make products on time. |

Adaptability to Change | Teams that work fast can fix problems that come up suddenly. |

Use solutions that make work easier and help you plan ahead for resources. Watch production quality by checking things like defects per unit, how often customers return items, and how well equipment works. These solutions help you keep high standards and make customers happy. Using the best methods gives you results you can trust.

Key Takeaways

Move fast to find urgent manufacturing orders. Use digital dashboards and sorting rules to pick important tasks first.

Make sure equipment works well and staff know what to do. Check machines often and train workers for different jobs. This keeps production moving when orders are urgent.

Use flexible schedules and manage resources well. Change plans when orders are urgent. This helps work go smoothly and finish on time.

Use automation to make fewer mistakes and work faster. Automated systems help process orders and check quality.

Keep good relationships with suppliers. Talk often and have backup plans. This stops delays and helps orders arrive on time.

Urgent Manufacturing Order Assessment

Order Identification

You must spot an urgent manufacturing order right away. Quick spotting lets you act fast and avoid delays that cost money. In busy factories, you can use rules to sort orders by how urgent they are. This helps you know which orders matter most. The table below lists some rules and when to use them:

Priority Rule | Description | Ideal Use Case |

|---|---|---|

Shortest Processing Time (SPT) | Picks tasks that finish the fastest. | Good for freeing up resources and keeping work moving. |

Longest Processing Time (LPT) | Starts with the longest jobs to stop slowdowns. | Helps stop big jobs from blocking other work. |

Earliest Due Date (EDD) | Handles orders by their due dates, starting with the soonest. | Needed to keep promises and avoid late fees. |

Custom Scheduling Rules (CSR) | Mixes different rules for special needs. | Lets you change plans to fit what is needed. |

Tip: Use digital dashboards to spot urgent manufacturing orders as soon as they show up. This helps you act fast and keeps your team working on the most important jobs.

Resource Availability

After you spot an urgent manufacturing order, check your resources right away. You need to know if your machines and staff can handle the new job without slowing down. Top manufacturers use clear numbers to see if they are ready. The table below shows two important numbers:

Metric | Description |

|---|---|

Capacity Utilization | Shows how much of your resources you are using. High numbers mean you are planning well. |

Rework Rate | Tells you how many products need fixing. High numbers mean there are problems that can slow you down. |

Look at machine schedules and staff work before giving out a new job. If you see high capacity utilization, you might need to move people or use backup teams. Fast response plans help you switch tasks quickly and keep things running smoothly.

Note: Keep your resource data up to date. This helps you avoid slowdowns and lets you act fast when urgent manufacturing orders come in.

Task Prioritization

You must put tasks in order to keep production order management working well. Use tools like the Eisenhower Matrix or a Kanban board to sort your jobs. These tools help you see what is urgent and important, so you do not miss deadlines.

Method | Description |

|---|---|

Eisenhower Matrix | Puts tasks into groups by urgency and importance. Helps you pick what to do now or later. |

Kanban Board | Shows tasks on a board. Lets your team see the status of each job. |

You can also use machine learning with the Important-Urgent Matrix. This helps you sort tasks automatically and focus on the most important jobs. Here is a simple way to group tasks:

Important and Urgent: Do these jobs first.

Important but Not Urgent: Plan these for later.

Not Important but Urgent: Give these to others or use machines.

Not Important and Not Urgent: Wait or skip these jobs.

Quick checks help you save time and avoid slowdowns. During the Covid-19 pandemic, groups like Médecins Sans Frontières used flexible steps to stay ready. They changed their work fast, which kept jobs moving and stopped problems.

Callout: Fast checks and clear sorting are key for strong production order management. They help you finish on time, avoid slowdowns, and keep customers happy.

Efficient Production Order Management

Workflow Optimization

You can make efficient production order management better by improving workflow. When you use digital tools to set up your steps, you make fewer mistakes. This keeps your team working together. It helps you finish each production order faster and with less trouble. Try these steps to make your workflow better and help order processing management:

Use digital tools to set up your steps. This helps stop mistakes and keeps everyone working together.

Make sure teams talk to each other. Central tools let teams share news and stop delays.

Look at data to find ways to get better. Numbers show where things are weak, so you can fix them.

Teach your team new skills. Training helps workers solve problems fast and handle urgent manufacturing orders.

Use IoT and automation. These tools help you find problems early and stop work from getting stuck.

Tip: Use a work order management system to watch every production order. This system helps you find slow spots and fix them before they cause trouble.

You should check your workflow with clear KPIs. The table below lists three important numbers for production order management:

KPI | Description |

|---|---|

Work Order Cycle Time | Time from work order creation to completion |

First-Time Fix Rate | Percentage of issues fixed on the first try |

Downtime Reduction | Decrease in equipment or process downtime |

When you look at these KPIs, you can see how your changes help efficient order processing and fulfillment. Better steps mean faster order delivery and happier customers.

Flexible Scheduling

Flexible production plans are important for efficient production order management. You need to change your schedule to fit the type of order and how fast it needs to be done. The table below shows how different orders change scheduling and fulfillment:

Order Type | Characteristics | Delivery Urgency |

|---|---|---|

Standard Orders | Fixed lead time, predictable demand | Relaxed customer required delivery |

Nonstandard Orders | Customized, variable lead times | Relaxed customer required delivery |

Emergency Orders | Short delivery requests, urgent regardless of cost | Immediate production arrangement needed |

Flexible scheduling helps you handle urgent jobs without using too many resources. You can use a work order management system to send skilled workers where they are needed most. This keeps production order management easy and smooth.

Quick access to skilled workers keeps your plan working.

Flexibility helps you handle busy times without wasting resources.

Fast action during worker shortages stops downtime and keeps orders moving.

Callout: Flexible production plans help you change quickly. You can keep order processing management strong and finish orders on time for every production order.

Automation in Order Handling

Automation changes efficient production order management. When you use automation for making, giving out, and watching work orders, you make fewer mistakes and finish order processing management faster. Automation also helps with quality control by stopping human mistakes and keeping standards high.

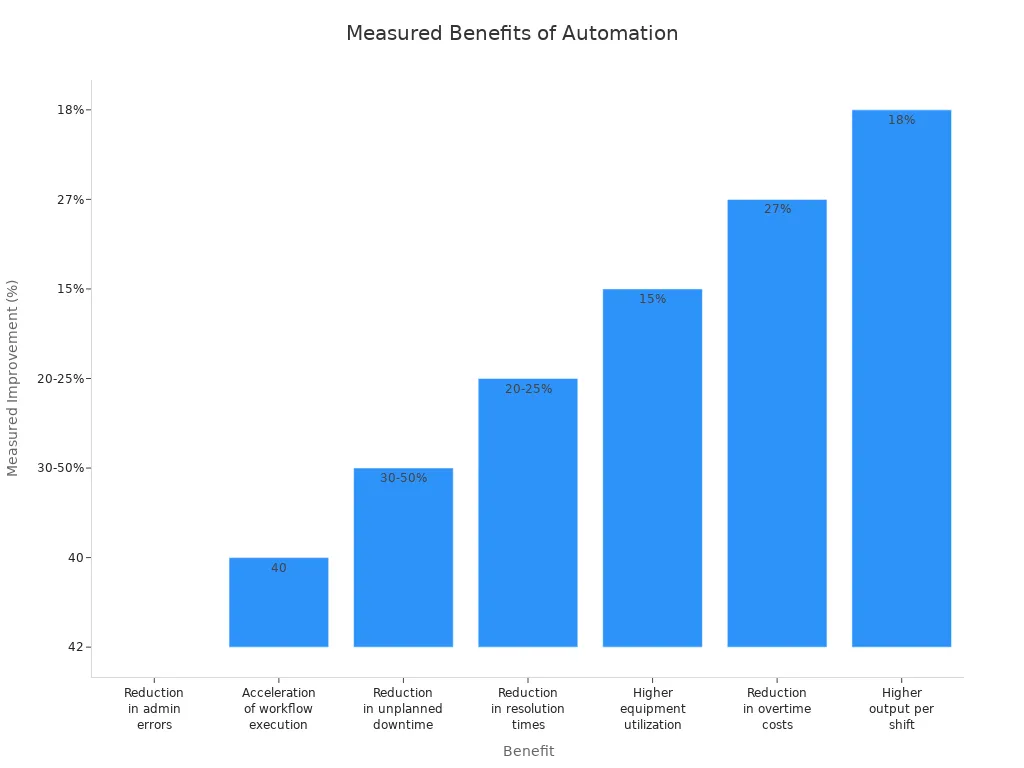

The chart below shows how automation makes order processing management better:

You can see clear benefits from automation in your work order management system:

Benefit | Measurement |

|---|---|

Reduction in administrative errors | 42% |

Acceleration of workflow execution | 30-50% |

Reduction in unplanned downtime | 55% |

Reduction in resolution times | 35% |

Higher equipment utilization rates | 20-25% |

Reduction in overtime costs | 15% |

Higher output per shift | 27% |

Lower operational costs | 18% |

Automation saves money and helps you get more done. You can finish more production orders with fewer mistakes. A good work order management system lets you watch every step, from making the order to finishing it. This system also helps with quality control by finding problems early.

Groups that use AI-powered production management software say they spend up to 52% less on ordering materials and services. Automation helps you look at supply chain data and fix problems before they get big. You can keep order processing management strong and steady.

Note: Automation helps with good work order management and flexible production plans. You can grow your solutions as your business gets bigger, keeping order fulfillment fast and correct.

Production Efficiency and Supply Chain

Material Availability

You must get materials fast for urgent production orders. Good production order management starts with risk management. Find risks like machine downtime or shortages. Keep spare parts ready. Use more than one supply chain to avoid delays. Work with many suppliers so you can switch if needed. Use digital tools to track inventory in real time. Hold daily meetings to keep everyone updated. Train your team to use multi-axis machines and new technology. These steps help production efficiency and keep your production order moving.

Strategy | Description |

|---|---|

Risk Management | Find risks and keep spare parts ready. |

Redundant Supply Chains | Work with many suppliers for backup. |

Effective Communication | Use digital tools and daily meetings for updates. |

Production Optimization | Make processes better to get more done. |

Employee Training | Teach workers new skills to stop downtime. |

Tip: Real-time inventory tracking helps you find shortages before they slow down production order management.

Supplier Coordination

You need to work well with suppliers to speed up urgent production orders. Fix problems like bad forecasting and poor inventory management. Plan ahead to stop issues before they happen. This lowers costs and helps order fulfillment. Try these steps for better supplier coordination:

Work with suppliers to speed up deliveries when needed.

Make backup plans with other suppliers.

Watch supplier performance and change schedules if needed.

Manufacturers who deliver on time build trust and make more money. If you miss deadlines, you may pay extra shipping fees or penalties. Good supplier relationships help efficient production order management and keep your production order on track.

Fix forecasting and inventory management problems to stay in control.

Use demand-driven planning to stop issues.

Lower inventory costs and help production efficiency by reducing expediting.

Inventory Buffer

You need an inventory buffer for urgent production orders. Focus on important inputs with long or uncertain lead times. In manufacturing, keep extra semiconductors or special metals. In construction, store materials for future phases. In healthcare, keep reserves of key medicines and equipment. Good inventory management stops work from stopping and helps order fulfillment.

Industry | Recommended Buffer Strategy |

|---|---|

Manufacturing | Keep extra important inputs with long lead times. |

Construction | Store materials for future phases. |

Healthcare | Keep reserves of key medicines and equipment. |

Note: Good inventory management and real-time tracking stop stockouts and delays in production order management.

Efficient CNC Factories

Efficient cnc factories act fast for urgent production orders. You can change schedules to put these jobs first. Use flexible production strategies like overtime or outsourcing to meet tight deadlines. Risk management helps you find problems like machine downtime or material shortages early. Efficient cnc factories use automation and better workflows to help production order management. You get faster delivery, better accuracy, and save money. These steps keep your production order moving and help order fulfillment.

Fast response puts urgent production orders first.

Flexible scheduling and outsourcing help meet deadlines.

Risk management finds and fixes problems early.

Step | Description |

|---|---|

Accurate Inventory | Stops stockouts and delays. |

Automation | Speeds up fulfillment and cuts errors. |

Efficient Picking Methods | Makes workflow better for urgent orders. |

Shipping Options | Gives fast delivery for urgent production orders. |

Real-time Tracking | Lets customers know about order fulfillment. |

Callout: Efficient cnc factories and good production order management keep your production order on time and your customers happy.

Communication and Collaboration

Team Coordination

Strong team coordination helps with urgent manufacturing orders. When your team works together, you make fewer mistakes. You finish jobs faster. Use clear communication for every production order. Set goals so everyone knows what to do. Good work order management needs everyone to know their tasks. The table below shows what helps teams work well:

Key Element | Description |

|---|---|

Effective Communication | Keeps everyone informed and focused on the same goals. |

Problem-solving and Critical Thinking | Helps your team fix problems quickly and find new solutions. |

Adaptability | Lets your team adjust to changes and new priorities. |

Attention to Detail | Prevents errors by tracking progress closely. |

Collaboration and Teamwork | Builds trust and helps teams work better together. |

Technical Proficiency | Uses project management tools to track and manage work orders. |

Tip: Use cloud-based work order management tools. These help your team share updates and solve problems together.

Real-Time Updates

Real-time updates make production order management better. You can see progress and spot issues early. This helps you change schedules fast. You keep production order delivery on track. Real-time data makes planning easier. It helps you control your workflow. The table below explains how real-time updates help:

Evidence Description | Key Insights |

|---|---|

Real-time data enhances production planning and control strategies | You respond faster to changes in demand and improve scheduling. |

Real-time control is easier in repetitive production environments | You collect more data and plan better. |

Real-time information aids in job completion and rescheduling | You reschedule jobs quickly and improve order accuracy. |

Note: Real-time updates in your work order management system help you avoid delays and reduce errors.

Customer Communication

You build trust with customers by keeping them updated. Use work order management software to send updates and notifications. Customers want to know about their orders and any changes. Good communication means fewer questions. It keeps customers happy. Try these strategies:

Give customers access to real-time tracking for their production order.

Share updates and tell customers about any delays.

Offer solutions if there are problems, like suggesting other options.

Use chatbots or automated systems to answer questions fast.

Callout: Good customer communication in production order management builds loyalty and reduces complaints.

Risk Mitigation and Adaptation

Contingency Planning

You need a good backup plan to keep urgent manufacturing orders going. First, find out what could go wrong in your order management system. Think about how likely each risk is and how bad it could be. Make clear plans to stop or lower these risks. Use a table to keep your main ideas organized:

Description | |

|---|---|

Multiple Suppliers | Have more than one supplier for critical components to reduce business risk. |

Buffer Stock | Maintain a buffer stock of essential components to prevent production delays due to supplier issues. |

Expedited Shipping Options | Utilize shipping companies that offer expedited options for urgent needs. |

Clear Communication Protocols | Establish clear communication protocols to ensure all parties are informed during disruptions. |

You should also make a plan for what to do if a risk happens. Set up emergency steps and backup plans. Build other ways to work if things change. These actions help you avoid long delays and keep your production line working.

Quick Problem-Solving

Solving problems fast helps your production order management stay flexible. Use step-by-step methods to fix issues quickly. The table below shows some ways that work well:

Description | |

|---|---|

Four-Step Sketch | Review key information, start design work, consider variations, and create a detailed solution. |

1-2-4-All | Brainstorm alone, then discuss in pairs, then in groups of four, and finally with all. This brings better ideas quickly. |

15% Solutions | Focus on small, quick fixes that teams can implement right away. These small changes can lead to big improvement. |

Tell your team to use these ideas. Let them act fast and share their thoughts. When you fix problems quickly, you keep urgent orders moving and help your team feel more confident.

Continuous Improvement

Making things better all the time helps you handle urgent manufacturing orders every day. Make sure everyone follows the same steps for work orders. Put the most urgent jobs first so machines keep running. Use technology like phones and cloud tools for real-time updates. The table below shows good ways to improve:

Description | |

|---|---|

Standardizing work order procedures | Uniform procedures boost efficiency and make tasks easier to track. |

Prioritizing work orders | Focus on urgent tasks to keep equipment running and reduce downtime. |

Enhancing communication | Real-time updates help everyone stay informed and reduce mistakes. |

Embracing technology and innovation | Mobile and cloud tools allow instant responses and support a dynamic workflow. |

Always look for small ways to make things better. Check your steps often. Ask your team what they think. Every small change helps you finish urgent orders faster and with better quality.

You can make production better by checking each urgent manufacturing order. Put tasks in order and make workflows simple. Good supply chain management and clear communication help you avoid problems. These steps help you get better results. Companies make more products, use equipment better, and finish jobs faster:

Description | |

|---|---|

Production Volume | Total number of products made in a set time. |

Overall Equipment Effectiveness (OEE) | Checks how much time equipment is working compared to all available time. |

Cycle Time | Average time needed to make one product. |

First Pass Yield (FPY) | Percent of units that meet quality rules without fixing. |

Production Downtime | Time when work stops; less downtime is very important. |

Quick Response Manufacturing can cut defect rates by 30%. It can also make customers 25% happier.

Order management systems help make orders more correct, faster, and improve talking with customers.

Act now. Use these ideas to get good order fulfillment and keep your customers happy.

FAQ

What is the fastest way to identify an urgent manufacturing order?

You can use digital dashboards to find urgent orders fast. Set rules to sort orders by how urgent they are. This helps you act quickly and stop delays.

How do you keep production quality high during urgent orders?

Track important numbers like defect rates and first pass yield. Use automation and regular checks to find problems early. Train your team to follow the right steps.

What tools help with team coordination for urgent orders?

Cloud-based work order management tools help teams share updates fast. Kanban boards show how tasks are moving. These tools help everyone stay focused and work together.

How can you avoid material shortages for urgent jobs?

Keep extra stock of important materials. Use real-time inventory tracking to find shortages early. Work with many suppliers so you have backup choices.

See Also

Boosting Engineering Efficiency Through Quick Response Techniques

Understanding Operating Indicators for Improved Manufacturing Outcomes

A Comparison of Discrete and Process Manufacturing Approaches

Enhancing Manufacturing Efficiency with Cutting Die Blanking Techniques

Essential Principles That Define Lean Manufacturing Practices

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.