3 Ways the Die Casting Pressure Curve Impacts Quality

You need to watch porosity, surface finish, and dimensional accuracy. These things affect how parts work and how dependable they are in factories.

Porosity and warping can happen if the mold or cooling is wrong, or if the molten metal injection does not work right.

A smooth surface finish and tight tolerances help you skip extra cutting and finishing steps.

Even wall thickness stops problems and keeps parts strong.

Low and high pressure die casting use different pressure levels, but controlling the Die Casting Pressure Curve is important for both. Tools like the p/Q diagram help you check and make your process better. You will see helpful tips and real-life examples that make these ideas easy to understand.

Die Casting Pressure Curve and Porosity

Pressure Curve Effects on Porosity

Porosity can make die cast parts weak and look bad. You might see small holes or bubbles in the metal. These problems happen when air or gas gets stuck during molten metal injection. The Die Casting Pressure Curve shows how pressure changes as metal fills the mold. If pressure gets too low or rises too fast, air pockets can form. You need steady and controlled pressure to push out trapped gases.

Low pressure die casting uses gentle force, usually from 0.7 to 1.5 bar. This way works well for simple shapes and thick walls. High pressure die casting uses much stronger force, often above 100 bar. You use this for thin walls and tricky shapes. Both ways need careful control of the Die Casting Pressure Curve. If you do not watch the curve, you can get porosity in both types.

Tip: Look for sudden drops or jumps in pressure during injection. These changes can cause porosity problems.

Reducing Porosity Through Curve Control

You can do things to lower porosity and make better parts. First, check your machine settings. Make sure the injection speed fits the mold design. Use sensors to watch the Die Casting Pressure Curve as you work. Change the pressure profile to keep it smooth and steady.

Here are some easy steps you can try:

Clean and dry the mold before each cycle.

Use vacuum systems to pull air out of the mold.

Set the right temperature for both metal and mold.

Pick the best injection speed for your part size.

Check the pressure curve data after each run.

Method | Effect on Porosity | Best For |

|---|---|---|

Low Pressure Casting | Less risk for thick parts | Simple shapes, wheels |

High Pressure Casting | Better for thin walls | Complex, small parts |

Vacuum Assist | Removes trapped air | All die casting types |

You can use these steps to control porosity and make parts stronger and more reliable. When you manage the Die Casting Pressure Curve, you help your team stop costly mistakes and extra work.

Surface Finish and Pressure Curve

Pressure Curve Impact on Surface Quality

You want your die cast parts to look smooth and clean. The surface finish matters because it affects how your parts fit and work. When you use higher casting pressures, you push the molten metal into every small space in the mold. This action helps you fill tiny details and avoid rough spots. A steady Die Casting Pressure Curve gives you a better surface because it keeps the metal moving at the right speed and pressure.

If you use low pressure or let the pressure drop, you might see problems. The metal may not reach every corner. You can get cold shuts, flow lines, or rough patches. These defects make your parts look bad and may cause them to fail in use.

Note: A smooth and controlled pressure curve helps you avoid surface defects and reduces the need for extra polishing or machining.

Optimizing Surface Finish

You can take steps to get the best surface finish from your die casting process. Start by checking your pressure settings. Make sure the pressure stays high enough during the fill. Use sensors to watch the pressure curve in real time. Adjust your machine if you see dips or spikes.

Here are some ways you can improve surface finish:

Keep the mold at the right temperature.

Use clean and well-maintained molds.

Set the injection speed to match your part’s shape and size.

Watch for leaks or blockages in the system.

Let’s look at a real-world example. A car parts maker noticed rough surfaces on their aluminum housings. They checked the Die Casting Pressure Curve and found sudden drops in pressure. After fixing the machine and keeping the pressure steady, the surface finish improved. They saved time and money because they did not need extra grinding.

Problem | Cause | Solution |

|---|---|---|

Rough surface | Low or unstable pressure | Raise and steady pressure |

Flow lines | Uneven metal flow | Adjust injection speed |

Cold shuts | Metal cools before filling | Keep mold temperature up |

You can use these tips to get smoother, better-looking parts every time.

Dimensional Accuracy and Pressure Curve

Achieving Precision with Pressure Curve

You want every part to fit the design. Dimensional accuracy means each piece fits and works right. The Die Casting Pressure Curve is very important for this. When you control pressure while filling the mold, the molten metal reaches all corners and edges. If pressure drops or jumps, the metal may not fill the mold. This can cause shrinkage cavities or parts that look wrong.

Here are some ways the pressure curve affects dimensional accuracy:

The pressure curve helps metal fill the mold fast and evenly.

Good pressure during filling and solidification stops shrinkage cavities.

Managing pressure keeps the part’s shape and size close to the design.

During mold filling, the piston pushes molten metal very fast, sometimes up to 100 meters per second. This fills the mold in just milliseconds. Right after filling, you need to raise the pressure. This step stops internal cavities and keeps the part strong.

If you keep pressure steady, you get better mechanical properties. Your parts will be more reliable and accurate than older casting methods.

Tip: Watch for sudden changes in the pressure curve. These can make parts that do not match the right size or shape.

Role of p/Q Diagram in Accuracy

You can use the p/Q diagram to check and improve dimensional accuracy. This tool shows how pressure (p) and flow rate (Q) work together during die filling. By looking at the diagram, you see if your hydraulic system can handle the process.

Here is how the p/Q diagram helps you:

It shows if pressure stays high enough while filling the mold.

You can find problems with hydraulic capacity before they hurt part quality.

The diagram helps you change machine settings for better accuracy.

Benefit of p/Q Diagram | How It Helps You |

|---|---|

Monitors pressure | Keeps pressure at target level |

Tracks flow rate | Ensures complete mold filling |

Finds system limits | Prevents accuracy problems |

When you use the p/Q diagram and control the Die Casting Pressure Curve, you make parts that fit and work well. You avoid expensive mistakes and keep production running smoothly.

Monitoring and Optimizing the Die Casting Pressure Curve

Practical Tips for Pressure Curve Control

You can make die casting better by using smart steps. First, check how fast and strong the injection is. Use computer tests to find the best settings for your mold and metal. Keep both the mold and metal at the right temperature. Watching the temperature in real time helps stop shrinkage and warping.

Here are some easy things you can do at work:

Connect your die casting machines to simulation software like ProCAST. This helps you control the piston and pick the best pressure.

Use computer tools to guess problems like gas porosity and stress. These tools help you save money and cut down on defects.

Try counter-pressure casting. Change process settings to help feeding and make parts stronger.

Make sure the compression phase comes right after filling. This makes casting pressure go up fast.

Use an intensifier plunger during filling. This raises pressure while the part gets solid.

Tip: Advanced monitoring systems help you see problems right away. You can fix them before they make bad parts.

Tools for Pressure Curve Monitoring

You have many tools to help you watch the Die Casting Pressure Curve as you work. These tools help keep your process steady and your parts good.

Measure vacuum in the mold and tank all the time.

Control vacuum settings to make the vacuum curve better.

Track filter dirt and chill block shapes.

Watch air flow for each vacuum channel.

Check how much air leaves and how good it is.

Control air wetness, mold tightness, and compressed air use.

Watch how well the vacuum pump works.

Digital tools like Fero Labs software help you lower surface defects. The software learns from each batch and gives safe tips. You can get up to 18% fewer scrap parts and 40% shorter surface cracks. AI and digital tools help you make smarter choices and cut scrap rates. Total Thermal Vision technology helps you manage downtime, especially when you change molds.

Simulation software lets you guess how molten metal will move and cool. You can use Moldflow analysis to test every step of the process. This helps you control pressure curves and find problems before they happen.

Technology | Benefit |

|---|---|

Simulation Software | Finds defects and improves settings |

Advanced Monitoring Tools | Cuts scrap and makes quality better |

Digitalization & AI | Helps you make smart choices and save resources |

Note: Training classes and certificates teach you how to use these tools. You can learn about simulating metal and practice with real exercises.

You can make die casting better by controlling the Die Casting Pressure Curve. This curve changes things like porosity, surface finish, and how close parts are to the right size. You should use new tools and systems to help your work.

FRECH casting units make pressure go up faster and help you work better.

MAGMA C+M and MAGMASOFT® 6.1 have automatic pressure calculators for quick tests.

MAGMAhpdc uses virtual gates to check die filling early.

Try these ideas to make your parts stronger and last longer. Keep learning new ways so you can do well in manufacturing.

FAQ

What is a die casting pressure curve?

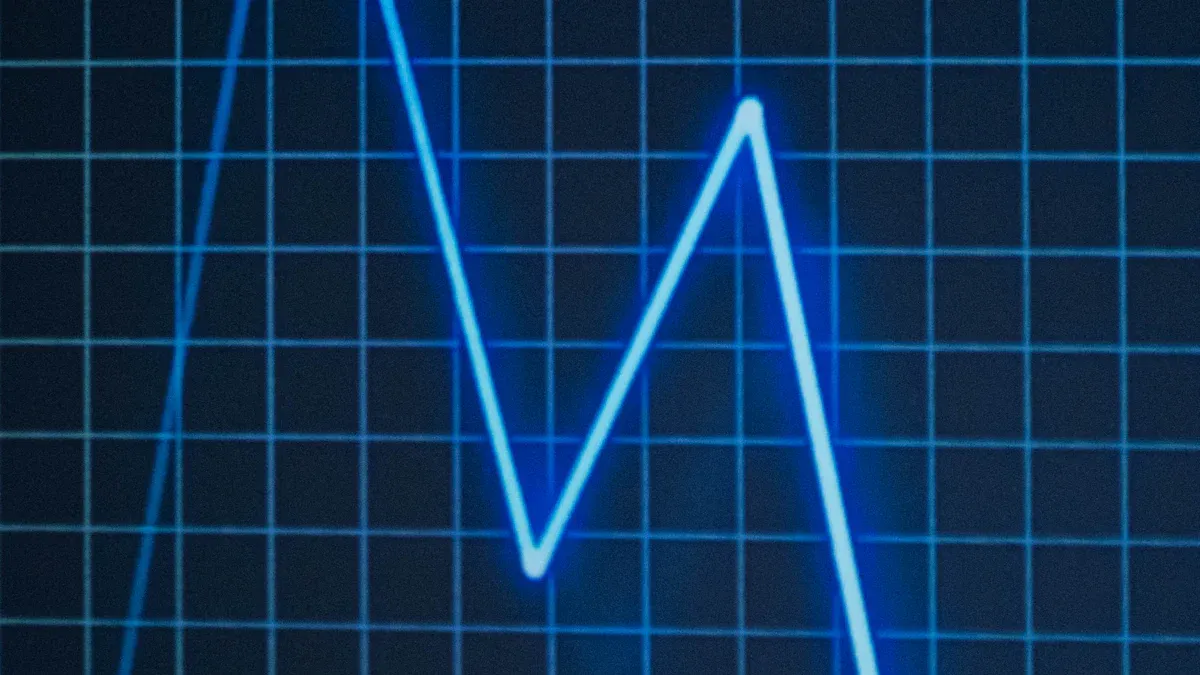

You see the pressure curve as a graph that shows how pressure changes during the die casting process. This curve helps you understand how metal fills the mold and how you can control part quality.

How does the pressure curve affect porosity?

You control porosity by keeping the pressure curve steady. Sudden drops or spikes in pressure can trap air in the metal. This creates small holes or bubbles in your parts.

Why does surface finish depend on pressure?

You get a smoother surface when you use higher and stable pressure. The metal fills every detail in the mold. If pressure drops, you may see rough spots or flow lines.

What tools help you monitor the pressure curve?

You can use sensors, simulation software, and digital monitoring systems. These tools track pressure in real time and help you adjust settings quickly.

Tip: Use software like ProCAST or Fero Labs to spot problems early and improve your results.

See Also

The Effects of Thermal Stress on Die Casting Components

Key Elements That Affect Die Cast Mold Pricing

Finding the Optimal Closing Force for Die Casting Products

Exploring CAE Analysis Advantages in Die Casting Design

Achieving Net Shape in Die Casting Processes Explained

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.