CNC Machining vs Casting: Finding the Right Balance for Cost and Quality

When you face the choice between CNC Machining vs Casting, you need to find the right balance for your project. You should think about your production volume, how much material you will use, and how complex your design is. If you understand these trade-offs, you can avoid costly mistakes. Careful planning helps you get the best cost and quality for your parts.

CNC Machining vs Casting: Quick Comparison

Summary Table

You can look at this table to see how CNC Machining and Casting are different. The table shows cost, quality, scalability, and how well each uses material.

Factor | Casting | Machining |

|---|---|---|

Cost | Cheaper for each part when you make many | Costs more for each part, wastes more material |

Quality | Not as exact (about ±0.1 mm or more) | Very exact (up to ±0.0002″) |

Scalability | Good for making lots, especially with set molds | Works for many but not as good for huge amounts |

Material Efficiency | Leftover material can be melted and used again | Chips can be recycled but need extra work |

Key Takeaways

Pick CNC Machining or Casting based on what your project needs.

Casting is best if you want lots of parts and want to spend less. You can use leftover material again, so you save.

CNC machining makes parts very exact. You get smooth parts and tight fits. It works well for small groups or tricky shapes.

If you need thousands of parts, casting saves money over time. CNC machining costs more for each part, especially with pricey materials.

Both ways let you recycle waste. Casting lets you melt scrap easily. Machining needs more work to recycle chips.

Scalability is important. Casting is better for big orders. CNC machining is good for small jobs or custom pieces.

💡 Tip: Always pick the method that fits your design, budget, and how many parts you need. CNC Machining vs Casting is not always the same answer for every project.

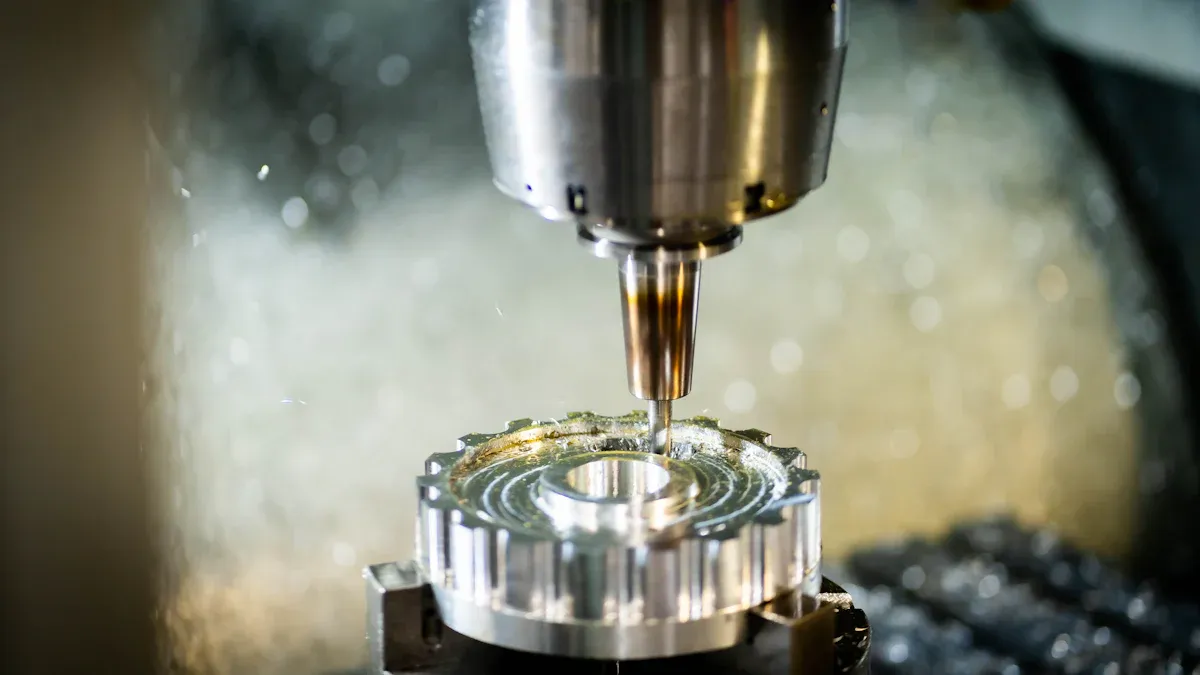

CNC Machining Overview

How It Works

CNC machining uses computers to control machines that shape parts. You start with a block or rod of material. The machine cuts, drills, or mills the block. It follows your design from a digital file. This makes parts with tight tolerances and smooth surfaces.

You can pick from many materials. Each one changes how the machine works. Here is a table with common materials and their properties:

Material Type | Properties | Machining Impact |

|---|---|---|

Carbon Steel (C45) | Cost-effective, easy to machine | Used in cars and buildings; good cutting speed |

Tool Steel (1.2842) | Very hard, resists wear | Needs special tools and cooling |

Stainless Steel 303 | Easy to machine, less corrosion resistance | Good for large batches; can harden during machining |

Stainless Steel 316L | High corrosion resistance, harder to machine | Used in marine and medical parts; costs more |

Brass | Soft, easy to shape | Great for complex parts; used in cars and ships |

Copper | Conducts electricity and heat well | Easy to cut; ductile, can form edges |

Titanium (Grade 5) | Strong, light, resists corrosion | Needs slow cutting and special tools |

ABS | Strong, heat-resistant, easy to machine | Used for prototypes; versatile |

POM (Delrin) | Rigid, low friction, stable | Good for gears and bearings |

PEEK | Stable at high temperatures, resists chemicals | Can replace metals; needs careful machining |

🛠️ Tip: Choose your material based on what the part will do. Some metals need special tools or slower speeds.

Strengths and Applications

CNC machining gives you very accurate and repeatable parts. You can make parts with tight fits and smooth surfaces. It is flexible for custom designs and small batches. You can change your design fast without new molds.

Many industries use CNC machining. Here are some examples:

Automotive: Engine parts and body panels

Aerospace: Aircraft wings and landing gear

Electronics: Circuit boards and connectors

Medical: Surgical tools and implants

Energy: Wind turbine parts and pressure vessels

Marine: Ship components

Agriculture: Machinery parts

CNC machining helps you make complex shapes with exact sizes. For example, you can make airplane turbine blades or titanium hip replacements. You get parts that meet strict standards.

Note: CNC machining is best when you need precision, flexibility, and quality.

Casting Overview

How It Works

Casting lets you make parts by pouring melted metal into a mold. The mold is shaped like your design. The metal cools down and gets hard inside the mold. When it is ready, you take the mold away. Now you have your finished part. There are different ways to do casting, and each way gives different results.

Investment casting uses molds that are lost after each use. This way gives smooth surfaces and shapes that are very close to your design.

High pressure die casting is good for making lots of parts fast. You often use metals like zinc, aluminum, or magnesium for this method.

You pick the casting method by thinking about your part’s size, shape, and how many you need. Some ways are better for small, detailed parts. Other ways help you make many parts quickly.

💡 Tip: Casting is great for making shapes that are hard to machine. It can save you time and money if you need lots of parts.

You also need to pick the right metal for your part. Each metal has special things it can do. These things change how your part will work. Here is a table to help you see what different casting metals can do:

Material | Properties Influencing Final Product |

|---|---|

Aluminum | Melts at a low temperature, flows well, and is light |

Steel | Very strong and tough, good for building things |

Stainless Steel | Does not rust, looks nice, and is strong |

Zinc | Melts easily, flows well, good for small and tricky shapes |

Magnesium | Very light, strong for its weight |

Strengths and Applications

Casting has many good points. You can make parts with tricky shapes and tiny details. You can make thousands of parts at the same time. You also use less metal because you only use what you need for the shape.

Many jobs use casting to make important parts:

Automotive: Engine blocks, drivetrains, and body panels

Agriculture machines: Wheels, hubs, and brake drums

Building and construction: Pipes, sewer castings, and fittings

Electrical engineering: Transformers, generators, and motor parts

Medical engineering: Device housings and prostheses

Ship building: Large engines and marine components

Aerospace: Turbines, jet engines, and aircraft structures

Energy: Pumps, valves, and wind turbine hubs

Railway engineering: Engine parts and safety systems

Mining: Custom castings for heavy equipment

You see casting in many places. It helps make strong and safe parts for cars, planes, and even medical tools. Casting gives you choices, speed, and can help you save money on your project.

Cost Factors: CNC Machining vs Casting

Upfront and Per-Part Costs

When you compare CNC machining and casting, you need to look at both the upfront costs and the cost for each part. CNC machining does not need special molds or tooling. You can start making parts right away, but each part takes time and uses more material. Casting needs a mold, which costs a lot to make at first. If you only need a few parts, this mold cost makes casting expensive.

You can see how costs change with the number of parts in the table below:

Volume (Units) | Casting (Tooling + Unit) | Machining (No Tooling) | Best Choice |

|---|---|---|---|

1–100 | High tooling cost, not viable | Higher unit cost but flexible | Machining |

100–1,000 | Tooling cost still dominant | Still costly but precise | Depends on design |

1,000–10,000 | Tooling cost spread out, low unit | Very high overall cost | Casting |

10,000+ | Most cost-effective | Not viable | Casting |

If you only need a few parts, CNC machining gives you more flexibility. You do not pay for expensive molds. When you need thousands of parts, casting becomes cheaper for each part because the mold cost spreads out over many pieces.

The common belief is that manufacturing costs per unit decrease as production volumes increase. While this holds true for mass production scenarios, such as pressure die casting or injection molding, it requires a substantial investment in expensive tool steel.

The initial cost of creating a die casting mold can be high, but the cost per part decreases significantly as production volume increases. In contrast, sand casting is often more cost-effective for lower-volume production runs, where the cost of creating a mold is lower. However, the cost per part can be higher than die casting, especially for parts with complex geometries or thin walls.

Material Efficiency and Waste

Material efficiency plays a big role in your total cost. CNC machining starts with a solid block and cuts away what you do not need. This process creates waste, called chips or swarf. You can recycle these chips, but it takes extra work and energy. Casting uses only the amount of metal needed to fill the mold. You get less waste, and you can often melt and reuse leftover metal right away.

Here is a table that shows how material efficiency affects your costs:

Factor | Impact on Cost |

|---|---|

Material Efficiency | Reduces waste, lowers labor and machine operating time, leading to cost savings. |

Production Volume | Higher volumes leverage economies of scale, reducing per-unit costs. |

Material Selection | Choice of material affects machining costs; rigid materials may increase costs. |

If you want to save money on materials, casting usually works better for large batches. You waste less metal, and you spend less time recycling. CNC machining can cost more if your part has a lot of extra material that gets cut away.

Volume and Scalability

The number of parts you need changes which process works best. CNC machining gives you fast setup and easy changes for small batches. You can make one part or a few hundred without waiting for molds. This helps if you want to test a design or make custom parts.

Casting works best when you need thousands of the same part. The high cost of making a mold pays off when you use it many times. Each part costs less as you make more. If you plan to scale up production, casting gives you the lowest price per part.

When you look at CNC Machining vs Casting, think about how many parts you need now and in the future. If you expect to grow, casting may save you money in the long run. If you only need a few parts or want to change your design often, CNC machining gives you more control and less risk.

Tip: Always match your process to your project size. Small runs favor CNC machining. Large runs make casting the better choice.

Quality Factors: CNC Machining vs Casting

Precision and Tolerances

You should think about how exact your parts need to be. CNC machining makes parts that fit together very well. This is important for things like airplanes, where every detail matters a lot. CNC machines use computers to follow designs closely. They cut, drill, and shape parts with high accuracy.

Casting is not as exact as CNC machining. The way the metal cools and the mold’s quality can change the part’s size or shape. Some casting methods, like precision casting, can get closer to tight fits. But most cast parts have more changes in size.

Here is a table that shows the usual tolerance ranges for each process:

Process Type | Tolerance Range |

|---|---|

CNC Machining | ±0.005″ (±0.127 mm) for general, ±0.002″ (±0.051 mm) for high precision, and as tight as ±0.0002″ for precision machining |

Casting (Aluminum) | ±0.25mm for dimensions up to 25.4mm, precision casting can achieve tolerances of 0.01″ and as fine as 0.002″ per inch |

Casting (Zinc) | Tighter tolerances can be attained compared to aluminum casting |

If you work in aerospace or need medical parts, CNC machining is best. You get the accuracy and sameness needed for important jobs. The machines use digital files, so every part matches your design.

Tip: Always check what tolerance your project needs before you pick CNC machining or casting.

Surface Finish and Defects

How your part looks and works depends on the surface finish. CNC machining makes smooth surfaces. You can change the finish by using different tools and speeds. Most CNC machined parts do not need much extra work. You get clean edges and a shiny look.

Casting can leave marks or problems on the surface. The way metal cools in the mold can cause issues. Here are some common problems you might see in cast parts:

Porosity: Air pockets or holes in the casting from trapped gas. These can make the part weaker and look rough.

Shrinkage: Empty spots from the metal getting smaller as it cools. This happens more in thick parts.

Hot Tears: Cracks that form when the metal cools at different rates. You see these in big or tricky castings.

Inclusions: Bits of other stuff like oxides or slag in the casting. These can make the part less strong.

You can fix some casting problems by grinding or polishing. But these fixes take more time and money. CNC machining usually gives you a better finish right away.

Note: If you want a part that is smooth and has sharp details, CNC machining is the better pick.

Consistency and Reliability

You want every part to work the same way. CNC machining gives you high sameness. The machines follow the same program for each part. You get steady results, which is important for cars, planes, and medical tools. Studies show CNC machining makes strong and reliable parts.

Casting also gives good sameness, especially with die casting. This method uses strong molds and controls the process well. You get parts that are the same, even in big batches. Die casting helps you meet high standards for making lots of parts.

Makers use different ways to check reliability. Here are some examples:

Brabant Alucast uses advanced die casting and machining for big car parts. They focus on making sure parts work well.

Heckert’s HEC machines are fast and flexible. They help make reliable parts.

Special control and checking devices in machining keep parts accurate for a long time. These are important for automated work.

Optical checks look at the surface and link it to how well the part works. This is important for machined parts.

You should pick CNC machining if you need every part to match exactly. Casting is good for big batches where you want all parts to be the same. Both ways can meet high standards, but CNC machining gives you more control over each part.

Tip: For projects where sameness and reliability matter most, CNC machining is often the safer choice.

CNC Machining vs Casting gives you different choices for quality. You need to pick the process that fits your project’s needs for accuracy, surface finish, and reliability.

Other Decision Factors

Design Flexibility

You want your design to work for you. CNC machining lets you change shapes fast. You can update your digital file easily. Then you make new parts without waiting. This helps when you test ideas or need custom pieces. Casting is better for designs that do not change. If you change your design a lot, you pay more for new molds. CNC machining lets you try new ideas with less cost and risk.

Lead Time and Speed

Speed is important when you need parts quickly. CNC machining starts right away because you do not need molds. You upload your design and begin cutting. Casting takes longer with old methods. You have to wait for molds to be made. Rapid casting uses 3D printed molds to save time. Here is how lead time compares:

Rapid casting skips making patterns and is faster.

3D printed molds in casting help you wait less.

Traditional casting and CNC machining need more time for molds.

If you want quick samples, CNC machining and rapid casting are faster.

Material Options

You can pick from many materials for both CNC machining and casting. Your choice changes how strong, light, or tough your part is. Metals are good for strong and exact parts. Plastics are light and easy to shape. The table below shows common choices:

Material Type | Characteristics | Applications |

|---|---|---|

Metals | Durable, strong, versatile | High-precision components |

Plastics | Lightweight, customizable, insulates | Prototyping, electronics |

Your material choice changes strength, weight, and cost. Metals give you strong and exact parts. Plastics help with lightness and easy use. Pick the material that fits your project best.

Strength and durability decide how long your part lasts.

Weight affects how easy it is to use or move.

Thermal and electrical properties matter for special uses.

Cost changes with the material you pick.

Sustainability

You want to help the environment when making parts. Casting uses less energy, especially for big batches. It melts only what you need for each part. CNC machining cuts away extra material, which makes waste like shavings and coolant. This waste can hurt the environment. You can recycle and use smart software to cut waste by up to 30% and save energy.

Casting uses less energy than CNC machining.

Big batches with simple shapes make casting greener.

Complex parts need machining, which makes more waste.

If you care about the planet, casting works better for big jobs. You can also make CNC machining better by recycling and using smart settings.

When to Choose CNC Machining

Ideal Scenarios

Pick CNC machining if you need parts that are exact and dependable. This method is good for projects that need quick changes or only a few parts. If your design is tricky, CNC machining can make shapes that other ways cannot do. You can also use special materials, like titanium or strong plastics, which are hard to cast.

Here is a table to help you see if CNC machining is right for your project:

Project Type | Advantages of CNC Machining | Cost Consideration |

|---|---|---|

Prototypes | You can change your design fast and make just a few parts. | Low start-up costs |

Small Series | You do not pay for costly molds and can make small batches easily. | Reliable costs for small amounts |

Complex Geometries | Machines use your CAD files to make detailed shapes with great accuracy. | High quality for tricky designs |

Metallic or Special Materials | You can use tough or rare materials for special needs. | Cost depends on the material |

💡 Tip: If you want to try a new idea or need a custom part, CNC machining gives you speed and flexibility.

Common Pitfalls

You might have problems if you do not plan well. Some people think buying a pricier CNC machine always makes better parts. But even the best machines can make mistakes without good setup and training. Remember, precision and accuracy are not the same thing. A machine can repeat the same mistake if you do not check both.

Here are mistakes you should avoid:

Thinking a more expensive machine always means better accuracy. You need good setup and skilled workers.

Mixing up precision and accuracy. Always check both to get the right parts.

Forgetting how important the operator is. Well-trained workers make better parts, even with simple machines.

Trusting software too much. Test cuts help you find real problems.

Picking speed over stability. Fast machining can cause heat and tool wear, which lowers accuracy.

⚠️ Note: You should spend money on training and quality checks, not just on fancy machines. Careful planning helps you avoid mistakes and get the best results from CNC machining.

When to Choose Casting

Ideal Scenarios

You should choose casting when you need to make a large number of parts with the same shape. Casting works best for parts with complex shapes that would be hard or expensive to machine. If your design has curves, hollow sections, or fine details, casting can help you get the results you want. You can also save money on each part when you produce thousands at a time.

Casting is a good choice for these situations:

You want to make thousands of identical parts.

Your part has a complex or detailed shape.

You need to use less material and reduce waste.

You want to keep the cost per part low for high-volume production.

You need to use metals like aluminum, steel, or zinc.

💡 Tip: If your project needs strong, detailed parts in large numbers, casting gives you a cost-effective solution.

Common Pitfalls

Casting does not fit every project. You may face problems if you pick casting for small batches or parts that need very tight tolerances. Some casting methods, like investment casting, have higher initial costs because you need special molds and patterns. You also wait longer for your first parts since mold production takes time. Not all materials work well with every casting method, so you may need special equipment for certain metals.

Here is a table that shows common pitfalls when choosing casting for low-volume or precise parts:

Pitfall | Description |

|---|---|

Higher initial cost | Investment casting has higher tooling costs compared to other methods. |

Longer lead times | The process requires more time for pattern and mold production. |

Material limitations | Certain materials may not be suitable for investment casting without special equipment. |

⚠️ Note: Always check your project’s size, timeline, and material needs before choosing casting. For small runs or high-precision parts, you may spend more time and money than expected.

Combining Casting and CNC Machining

Benefits of a Hybrid Approach

You can get the best results by combining casting and CNC machining. This hybrid approach helps you save money and use materials wisely. When you cast a part first, you create the basic shape with less waste. After casting, you use CNC machining to add fine details or tight fits. This method lets you make strong parts with smooth surfaces and exact sizes.

You do not need to machine the whole part from a solid block. You only machine the areas that need high precision. This saves time and reduces the amount of material you waste. You also lower your costs because casting is cheaper for large shapes, and machining is best for small, detailed features.

Tip: Use casting for the main shape and CNC machining for the final touches. This way, you get both speed and accuracy.

When to Consider Both

You should think about using both methods when your project needs both complex shapes and high precision. Here are some situations where a hybrid approach works well:

You need thousands of parts with detailed holes or threads.

Your part has a complex outer shape but needs smooth, flat surfaces in some areas.

You want to save money on material and labor.

Your design needs both strength and tight tolerances.

For example, car engine blocks often start as castings. After casting, you machine the surfaces where other parts will connect. This makes sure everything fits perfectly. In aerospace, you might cast a part for its shape, then machine the edges for a perfect fit.

CNC Machining vs Casting does not have to be an either-or choice. By combining both, you get the benefits of each process and avoid their limits.

Decision Guide

Step-by-Step Process

You can follow a simple process to choose between CNC machining and casting. This guide helps you avoid mistakes and pick the best method for your project.

Define Your Needs

Write down what you want your part to do. Think about size, shape, and how strong it must be.Estimate Production Volume

Count how many parts you need. Small batches work better with CNC machining. Large batches fit casting.Check Design Complexity

Look at your design. Complex shapes or fine details may need casting. Tight fits and smooth surfaces point to CNC machining.Choose Your Material

Pick the material that matches your part’s job. Some metals and plastics work better with one method.Set Your Budget

Add up your costs. Include setup, tooling, and per-part expenses. Casting saves money for big orders. CNC machining costs less for small runs.Consider Lead Time

Decide how fast you need your parts. CNC machining starts quickly. Casting takes longer if you need molds.

📝 Tip: Use this checklist before you start. It helps you match your project to the right process.

Real-World Examples

You can learn from real projects. Here are two examples:

Project Type | Best Method | Why It Works Well |

|---|---|---|

Custom Drone Parts | CNC Machining | Needs tight fits and quick changes |

Car Engine Blocks | Casting + Machining | Needs thousands, complex shape, precision |

A drone company needs lightweight, custom parts. You choose CNC machining for fast changes and exact fits.

A car maker needs thousands of engine blocks. You pick casting for the main shape. You use CNC machining for smooth surfaces and tight fits.

💡 Note: Your project may need both methods. Always check your needs before you decide.

CNC machining and casting each have their own good points for cost and quality. Look at what your project needs before you pick one. Think about how many parts you need, your design, and the material. Sometimes, using both methods together works best.

Check both choices for every project.

Talk to people who know a lot.

Get price quotes to see what you will pay.

💡 Tip: Plan ahead so you do not make mistakes and get the most for your money.

FAQ

What is the main difference between CNC machining and casting?

CNC machining cuts parts from solid material using computer control. Casting pours melted metal into a mold to form a shape. You get higher precision with CNC machining. Casting works better for large quantities and complex shapes.

Can you combine CNC machining and casting for one part?

Yes! You can cast the basic shape first. Then, you use CNC machining to add fine details or tight fits. This method saves time and material while giving you both strength and accuracy.

Which process is faster for small orders?

CNC machining usually gives you faster results for small batches. You do not need to wait for molds. You can start production as soon as you finish your design.

How do I choose the right process for my project?

Think about how many parts you need.

Check your design’s complexity.

Decide how exact your parts must be.

Set your budget.

Ask for expert advice if you feel unsure.

Are both CNC machining and casting eco-friendly?

You can recycle waste from both methods. Casting often uses less energy for big batches. CNC machining creates more scrap, but you can recycle chips. Smart planning helps you lower your environmental impact.

See Also

Exploring Advantages of CAE Analysis for Die Casting Design

Defining Functional Testing in CNC and Die Casting Methods

A Supplier's Guide to CBAM and Sustainable Casting Practices

Finding Optimal Closing Force for Your Die Casting Product

Comparing Aluminium and Magnesium for Lightweight Die Casting

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.