CNC machining for automotive aluminum ADC12 made simple

CNC machining for automotive aluminum adc12 lets you make exact and tough parts. These parts meet the strict rules in the car industry. You use cnc to cut and shape the metal. It turns raw aluminum into detailed, high-quality pieces. This process gives you strong and dependable parts. These parts help cars stay safe and work well.

If you pick ADC12 aluminum, you get a great mix of strength and easy shaping for car needs.

ADC12 Aluminum Overview

Properties and Composition

ADC12 aluminum alloy is used a lot in cars. It has a mix of different elements. This mix gives it strength and makes it light. It is also easy to shape. Aluminum is the main part of this alloy. Other elements like silicon, iron, and copper are added. These help the alloy work better. They make it stronger and help it last longer.

Here is a table that shows the usual chemical makeup of ADC12 aluminum for cars:

Grade | Al (%) | Si (%) | Fe (%) | Cu (%) | Ga (%) | Mg (%) | Zn (%) | Mn (%) | Others (%) | Sum (%) |

|---|---|---|---|---|---|---|---|---|---|---|

Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | 0.010 | 0.10 | |

Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | 0.015 | 0.15 | |

Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | 0.030 | 0.30 | |

Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | 0.030 | 0.40 | |

Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | 0.030 | 0.50 | |

Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | 0.050 | 1.00 |

Note: The high amount of aluminum keeps it light. Silicon and copper make it stronger and tougher.

Why ADC12 for Automotive Parts

Car parts need to be strong and last a long time. ADC12 is better than many other metals. It lets you make tricky shapes and thin parts that are still strong. You can make parts quickly and they look smooth. This saves both time and money.

Here is a table that shows the main good things about using ADC12 in car die casting:

Advantage | Description |

|---|---|

High dimensional stability | Good for tricky shapes, thin parts, and deep spaces |

High efficiency and quick production speed | Parts can be made and sent out fast |

Superior surface quality | Smoother finish than old casting ways |

Good corrosion resistance | Parts do not rust easily and last longer |

Strong mechanical properties | Stays strong in many different situations |

High thermal and electrical conductivity | Moves heat and electricity very well |

Retains strength at high temperatures | Works well even in hot engine places |

ADC12 can handle heat and stress in cars. It keeps its shape and strength when it gets hot. It also fights rust, so parts last longer. If you pick this metal, your car parts will stay safe and work well.

CNC Machining for Automotive Aluminum ADC12

Machining Process Steps

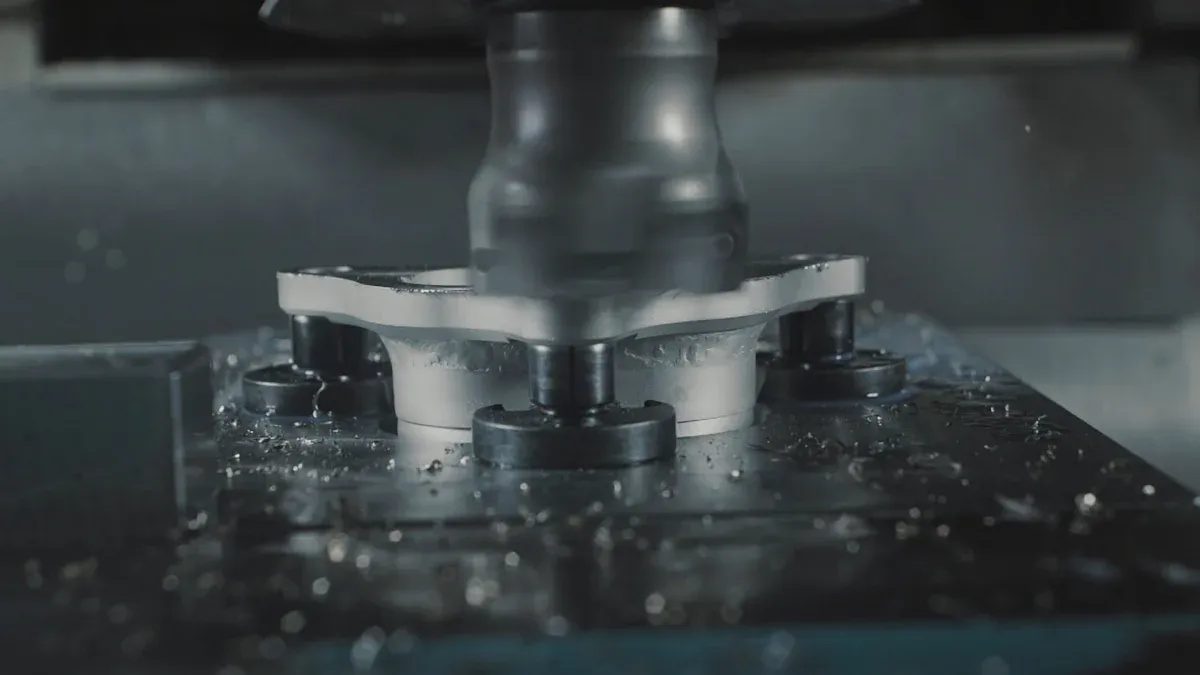

You start with a block or die-cast part made from ADC12 aluminum. The process begins with careful preparation. You secure the part in the CNC machine. You check the design and set the right tools. The machine uses sharp cutters to remove extra material. This is called a subtractive process. You shape the part step by step. The machine follows a computer program. This program tells the machine where to cut and how deep to go.

You can use different tools for drilling, milling, or turning. Each tool has a special job. Drills make holes. Mills shape flat or curved surfaces. Lathes spin the part to cut round shapes. After cutting, you check the part for rough edges. You use finishing tools to smooth the surface. You may also clean the part to remove dust or chips. This makes the part ready for the next step.

Secondary Operations on Die Castings

Many car parts start as die castings. These parts often need extra work to meet strict car standards. CNC machining for automotive aluminum adc12 helps you add details that casting cannot make. You can drill precise holes, cut slots, or add threads. These steps are called secondary operations.

You use CNC machines to finish these castings. The machine can reach tight spaces and make small features. You can also fix any small mistakes from casting. This makes sure every part fits and works well in the car. You get smooth surfaces and sharp edges. The finished part looks good and works better.

Tip: Always check the part after each step. This helps you catch problems early and keep quality high.

Achieving Precision and Complexity

CNC machining for automotive aluminum adc12 lets you make parts with very tight tolerances. You can create thin walls and complex shapes that are hard to make by hand. The machine follows the design exactly. This gives you high dimensional stability. You can trust that each part will match the drawing.

Automotive parts need to fit together perfectly. CNC machining for automotive aluminum adc12 helps you reach this goal. You can make parts that are both strong and light. The process works well for engine parts, brackets, and covers. You can also repeat the process many times. Each part will look and work the same.

Note: High dimensional stability means your parts keep their shape, even when they are thin or have tricky designs.

CNC machining for automotive aluminum adc12 gives you the power to make advanced car parts. You get accuracy, speed, and great results every time.

Benefits of CNC Machining

Strength and Durability

When you use CNC machining for ADC12 aluminum, you get parts that last. The process removes weak spots and leaves a strong surface. This helps your parts handle stress and heat in cars. ADC12 aluminum resists rust, so your parts stay in good shape for a long time. You can trust these parts to keep working, even in tough places like engines. The metal keeps its strength, so your car stays safe and reliable.

Tip: Strong parts mean fewer repairs and less worry about breakdowns.

Accuracy and Repeatability

CNC machining gives you very precise parts every time. The machine follows your design exactly. You can make many parts, and each one will match the others. This is important in the automotive industry, where every piece must fit just right. You can expect tight tolerances, often reaching ±0.05mm. This level of accuracy means your parts work well together and help your car run smoothly.

Tolerances you can achieve with CNC machining for ADC12:

±0.05mm for most automotive components

You do not have to worry about mistakes or uneven parts. The process repeats the same steps for each piece, so you get the same quality every time.

Flexibility for Complex Parts

CNC machining lets you create shapes that are hard to make by hand. You can design thin walls, deep holes, or special curves. The machine can handle these tricky shapes with ease. If you need to change your design, you can update the computer program and start again. This flexibility helps you keep up with new ideas in car design.

You can use CNC machining for many different parts, from engine covers to brackets. The process works well with ADC12 aluminum and other types of metal. You get the freedom to make parts that fit your needs, no matter how complex.

Note: Flexibility in design helps you stay ahead in the fast-changing world of cars.

Common Automotive ADC12 Parts

Engine Components

ADC12 aluminum is used in many engine parts. CNC machining helps make engine blocks that meet strict rules. You get parts that are very exact and smooth. The process lets you make hard shapes, like channels for coolant or oil. You can make engine blocks fast, which saves time and money.

Here is a table that shows how CNC machining helps ADC12 engine parts:

Benefit | Description |

|---|---|

High Precision and Consistency | Makes parts with tight tolerances, down to ±0.005 mm. This means you get the same quality every time. |

Reduced Lead Time | Cuts out extra steps, so you finish parts faster and deliver them sooner. |

Complex Geometry Capability | Handles tricky designs and many surfaces in one go. It can use 5-axis machining for tough jobs. |

Tip: CNC machining makes engine parts that fit well and last a long time.

Housings and Brackets

ADC12 is used for housings and brackets in cars. The metal flows well when cast, so you can make detailed shapes. CNC machining makes these parts more exact and smooth. You get strong housings that protect electronics. Brackets hold other parts in place.

Dimensional stability keeps parts the right size.

High thermal conductivity helps control heat.

Great for shapes that need extra machining.

Note: ADC12 housings and brackets stay strong, even with heat and shaking.

Other Typical Parts

ADC12 is found in many other car parts. CNC machining lets you make covers, connectors, and electronic casings. You can make thin walls and big parts that are still exact. The process is quick, so you get parts in less than ten days. ADC12 is a cheap way to make many kinds of parts.

Here is a table that shows how ADC12 gives you more choices:

Material Type | Applications | Strengths | Characteristics |

|---|---|---|---|

Aluminum ADC12 | Housings, brackets, electronic casings | Easy to cast, saves money, makes exact parts | Lead Time: < 10 days, Wall Thickness: 0.75mm, Tolerances: ±0.125mm, Max part size: 200 x 80 x 100 cm |

Tip: ADC12 lets you make parts that are light, strong, and easy to shape.

Key Considerations for Machining ADC12

Machining Challenges

When you work with ADC12 aluminum, you face some tough machining challenges. The alloy contains hard silicon particles. These particles make the metal strong, but they also cause problems for your cutting tools. You may notice that your tools wear out much faster than usual. Tool life drops to only 20% compared to standard aluminum alloys. Even advanced tools can suffer from crater wear on the rake face and micro-chipping at the edge.

Severe tool wear from hard silicon particles

Crater wear on the tool’s rake face

Edge micro-chipping, even with advanced tools

Tool life reduced to 20% of normal

Tip: You should check your tools often and replace them before they break. This helps you keep your parts accurate and your process smooth.

Tips for Quality Results

You can get better results by following a few simple steps. First, choose cutting tools made for tough alloys. Carbide tools work well with ADC12. Use sharp tools and keep them clean. You should set the right cutting speed and feed rate. Lower speeds help reduce tool wear. Always use coolant to keep the metal and tools cool. This stops overheating and helps your tools last longer.

Here is a quick checklist for machining ADC12:

Step | What to Do |

|---|---|

Tool Selection | Use carbide or coated tools |

Cutting Speed | Set lower speeds for less wear |

Coolant Use | Apply coolant to prevent heat |

Tool Maintenance | Inspect and replace tools often |

Note: Clean your work area and remove chips after each step. This keeps your machine running well.

Quality Control

You need strong quality control to make sure every part meets car industry standards. Measure your parts after each machining step. Use gauges and calipers to check size and shape. Record your results and compare them to your design. If you find mistakes, fix them right away. You should also inspect the surface for rough spots or cracks. Good quality control helps you deliver safe and reliable parts.

Tip: Keep a log of your measurements and tool changes. This helps you spot problems early and improve your process.

CNC machining helps you make high-quality ADC12 parts for cars. You get strong, accurate, and complex shapes with less effort. Here are the main reasons to choose CNC machining for ADC12:

You achieve tight tolerances and smooth finishes.

You save time and reduce waste.

You can create custom parts for many car needs.

Consider CNC machining for your next ADC12 project. You will see better results and reliable performance.

FAQ

What is ADC12 aluminum used for in cars?

You use ADC12 aluminum for engine parts, brackets, and housings. It works well for parts that need to be strong and light. You can also use it for covers and electronic casings.

Why should you choose CNC machining for ADC12?

CNC machining gives you precise and repeatable results. You can make complex shapes and tight tolerances. This process helps you get strong, reliable parts for your car projects.

How do you reduce tool wear when machining ADC12?

Use carbide tools and set lower cutting speeds. Always apply coolant to keep tools cool. Check your tools often and replace them before they wear out.

Can you make custom car parts with CNC machining?

Yes! You can design special shapes and features. CNC machines follow your design exactly. You get custom parts that fit your needs.

See Also

A Comprehensive Guide to CAD Design for Die Casting

Exploring Functional Testing in CNC and Die Casting

The Significance of DFDC in the Automotive Sector

Comparing Aluminium and Magnesium for Lightweight Die Casting

Exploring CAE Analysis Advantages in Die Casting Design

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.