Why automobile suppliers are increasing capacity for the robot manufacturing industry

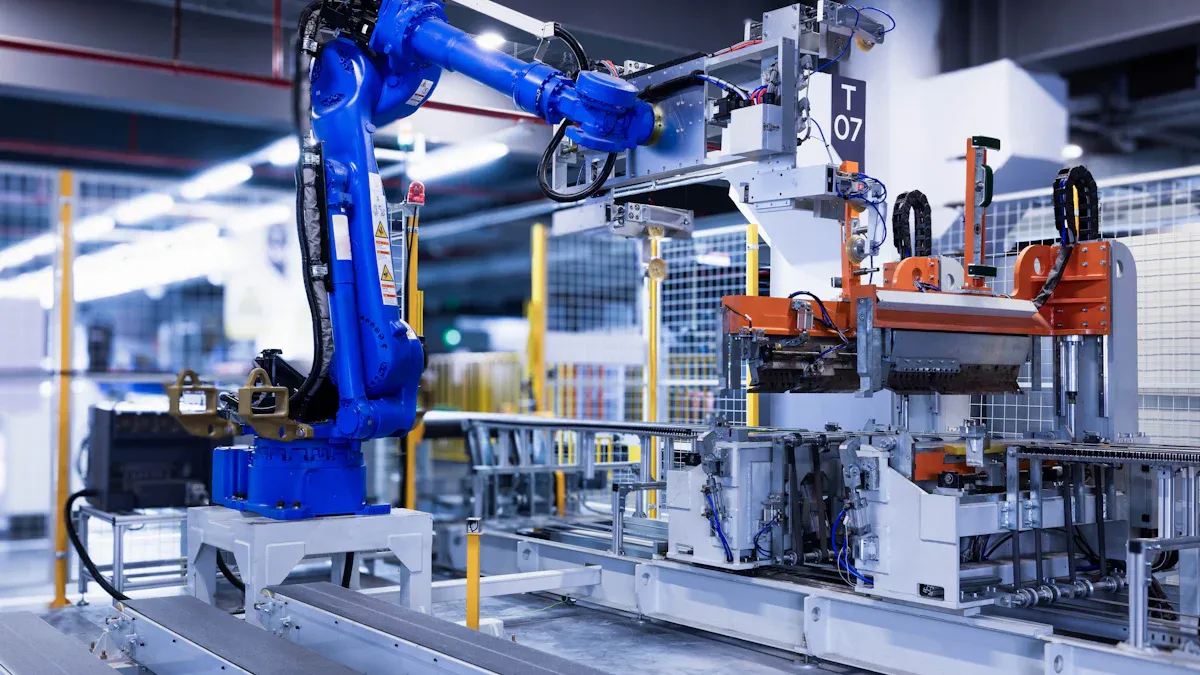

You see more automobile suppliers making more robots. They want to earn more money, work faster, and fix worker shortages. Automation and AI-powered robots help factories more now.

In Q1 2025, North American companies bought over 9,000 new industrial robots. This is a big jump from last year.

In 2023, the automotive sector in Europe put in almost 9,200 robots. That is 29% more than in 2022.

Supply chains for cars and robots often mix together. This makes the change easier and quicker.

Drivers of Capacity Expansion

Demand for Industrial Robots

Factories need more industrial robots now. They want to make more cars and parts. Every year, they use more robots. In the last ten years, robot use has doubled. In 2024, factories put in 542,000 new robots. China added 295,000 robots in one year. Experts say this number will keep going up. By 2028, it may reach over 700,000 robots.

Almost 40% of all industrial robots work in car factories. These robots help with welding, painting, and building cars. If you make car parts, you need to follow this trend. Robots help you make parts that are exact and high quality. This means fewer mistakes and better cars.

Here is a table that shows why car suppliers want more robots:

Evidence Description | Key Insights |

|---|---|

More automation helps with production and quality. | |

Demand for smart manufacturing and Industry 4.0 | Robots with AI, IoT, and cloud make work better. |

Need for enhanced efficiency and precision | New welding robots help work faster and waste less. |

Car factories use more robots than other industries. Asia Pacific and Europe are growing fast too. If you make car parts, you need robots to stay ahead.

Automation and Efficiency

Factories want to work faster and waste less stuff. Automation helps you do this. Robots let you make more things in less time. ZF Group used robots on its transmission line. Their output went up by 40%. They wasted 65% less material. Toyota used robots for painting. They used 25% less energy. Ford’s robot lines used 32% less energy and wasted 55% less metal. BMW’s robot checks cut rework by 80%.

You can use new robots like AI-powered robots, cobots, and AMRs. These robots make factories safer and more flexible. Cobots work with people and switch jobs quickly. AMRs move parts around and save time. AI-powered robots find mistakes fast and stop costly errors.

“AMRs and AGVs help car makers change old production lines. They can use small cells and swap them out without stopping work,” says Joerg Reger, boss at ABB Robotics’ car business.

Here are ways these robots help:

Cobots do many jobs and switch tasks fast.

You can add cobots quickly and see results soon.

AMRs keep your supply chain moving well.

AI-powered robots help stop accidents and keep workers safe.

Labor Shortages

Many factories cannot find enough workers. After the pandemic, over 40% of U.S. plants had trouble hiring. Factories made $1 trillion more in twenty years but had 5 million fewer workers. To keep up, they use more robots.

In 2022, North American companies ordered 44,196 robots. That was 11% more than last year. Electric vehicles need new skills. Workers who know new tech are hard to find. Robots fill this gap and keep factories running.

Electric vehicle demand will make robot use go up even more. Experts think automotive robotics will grow by 45% in four years. If you make car parts, you need more robots to meet these needs.

Automobile Supplier Benefits

New Revenue Streams

You can grow your business in new ways. Many automobile suppliers now make robots for factories. This helps you earn more money and find new customers. You do not have to sell only car parts. You can offer robot solutions to other industries like electronics or logistics.

Here is a table that shows how companies use robots to make more money:

Company Name | Robot Solution Used | Application Description |

|---|---|---|

G-TEKT | ABB’s robotic solutions | Handling heavy automotive components |

Beijing Automotive Group Co. Ltd. | ABB’s robots | Increasing electric car production |

JTEKT | FANUC’s robots | Increasing plant efficiency and productivity |

Seeger-Orbis GmbH | FANUC’s CNC machines | Manufacturing diverse range of automobile parts |

P.M.C. | KUKA AG’s modular robot cells | Welding applications |

More automobile suppliers in Germany use collaborative robots now. Big companies like Volkswagen, Daimler, and Ford add cobots to their lines. These robots help with electric and hybrid cars. Cobots improve precision and speed. This lets you offer new products and services.

Innovation and R&D

You can create new ideas by mixing automotive and robot technology. Many automobile suppliers work with robot makers to build new solutions. You can use your car part knowledge to design better robots. Working together leads to smarter machines and new ideas.

GAC’s GoMate humanoid robot uses automotive technology for jobs outside the factory. You can see it in places like security and elderly care.

The robot moves over different surfaces. This shows how design and function get better with new ideas.

GAC uses its supply chain to lower costs for making robots. You can do this too by sharing parts and systems between cars and robots.

You can work with robot makers to test new features. This helps you stay ahead in both industries. You can use your skills to solve problems and make products for many needs.

Impact on Robot Manufacturing

Reliable Supply Chains

Supply chains have changed a lot lately. Many companies had big problems. Automation helps you fix issues fast. Robots keep your factory working when parts are missing. If you can see all your suppliers, you can switch quickly. This helps you beat other companies that react slowly.

AI risk tools help you make smart choices. Toyota uses AI to check how suppliers do their jobs. They look at how fast, steady, and good the deliveries are. You can use these tools to pick the best partners. This makes your supply chain strong and safe.

Working with an automobile supplier gives you their network. You can share things and learn from them. This helps you avoid slowdowns and keep making robots.

Tip: Use automation and AI to find risks early. You can fix problems before they get worse and keep your business safe.

Faster Production

You want to build robots faster and spend less money. Automobile suppliers help you do this. They bring smart machines and systems to your factory. Cobots can help you work better and faster. These robots work with people and do hard jobs quickly.

Here is a table that shows how more capacity helps you make robots faster:

Evidence Description | Impact on Production Cycles |

|---|---|

McKinsey estimates that cobots can increase productivity by up to 20%. | Makes work faster and helps deliver new products quickly. |

Vitesco Technologies has automated component loading and unloading, cutting cycle times by 11%. | Makes production take less time. |

Toyota Motor Hokkaido has doubled work capacity on assembly lines while decreasing production costs. | Makes factories work better and cheaper. |

Automation helps you make things faster and better. Adding new robots lets you send products out quickly. You also save money and make higher quality robots. Automobile suppliers help you grow and meet more orders.

Challenges and Considerations

Investment Needs

You have to make big choices about spending money. In Japan, car companies spend a lot to change their factories. They want to make electric and hydrogen vehicles. You need new machines for these jobs. You also need to teach workers new skills. This costs more than other changes in business.

You should think about money risks and rewards. Here are some things to remember:

Always check if saving money is worth the cost.

A good plan helps you see real gains and avoid losing money.

Working better and making fewer mistakes can help you earn more.

Teaching your team well helps you get the most from automation.

Using humanoid robots can make your factory faster and better.

Note: Jaguar Land Rover spent £500 million on making electric cars, teaching workers about high-voltage, and fixing robots. This shows you may need to spend a lot to use new technology.

You can also train your workers. Many companies make their own training programs. They work with schools to teach new skills. This helps you keep up with changes in automation.

Quality Standards

You need to meet high standards when you start making robots. Car makers want suppliers who work fast and can change plans quickly. You must fill orders fast and be ready to change. This is hard if you do not have good systems.

You also have other problems:

You must make quick choices to keep up with changes.

Electric vehicles need new parts and ways to build them. You must update your factory for these.

The market can change quickly. Trade problems and price changes can hurt your profits.

Training workers to fix robots is now very important. Many companies teach their teams new skills.

Company | Investment Amount | Focus Areas |

|---|---|---|

Jaguar Land Rover | £500 million | Electric vehicle production, high-voltage training, robot maintenance |

You can solve these problems by making strong training programs and staying flexible. This helps you keep your quality high and get ready for the future.

You see automobile suppliers and robot makers teaming up for big benefits.

Factories work better, grow faster, and make things more exact.

Automation and AI help you check quality and keep track of supplies.

Collaborative robots make jobs safer and let people do harder tasks.

The robot market keeps getting bigger as fewer workers mean new ideas are needed.

Experts say automation pays off quickly and helps small businesses grow. You will see more robots in car factories and new ways to fix problems in both fields.

FAQ

What is the main reason automobile suppliers make more robots?

You see suppliers making more robots to earn more money and solve worker shortages. Robots help you work faster and make fewer mistakes. This lets you stay ahead in a changing market.

How do robots help with labor shortages?

Robots fill jobs when you cannot find enough workers. They do hard or boring tasks. This keeps your factory running and helps you meet customer needs.

Tip: You can train workers to use robots and keep your team strong.

Can small suppliers also benefit from robot manufacturing?

Yes! Small suppliers can use robots to grow their business. You can make products faster and with better quality. Robots help you compete with bigger companies.

What skills do workers need for robot factories?

Workers need to know how to use and fix robots. You can learn these skills through training programs or by working with robot makers.

Skill Needed | How to Learn |

|---|---|

Robot operation | On-the-job training |

Maintenance | Special classes |

Will robots replace all factory jobs?

No, robots will not take every job. You still need people to plan, fix, and watch over robots. Robots help you do more, but people stay important in every factory.

See Also

Die Casting's Role in Advancing the Robotics Industry

Choosing The Ideal Manufacturer For Robotics Startups

Essential Trends In The 2025 Automotive Die Casting Sector

Understanding APQP's Importance For Automotive And Aviation

Enhancing Manufacturing Efficiency Through Cutting Die Blanking

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.