What Aluminum Labels Dominate US, EU, China

Aluminium labels play a crucial role in various industries due to their versatility and durability. These labels, often seen in aerospace, construction, and automotive sectors, help identify specific aluminium alloys used in manufacturing. For instance, the ADC12 aluminium alloy is a popular choice for die casting in automotive and industrial automation. The focus on aluminium labeling systems in the United States, European Union, and China highlights the global significance of these labels. Each region employs unique systems to classify aluminium alloys, ensuring that industries can select the appropriate materials for their specific needs.

Aluminum Labeling System in the United States

Overview of the 4-digit designation by the Aluminum Association

Explanation of the system

The Aluminum Association in the United States uses a 4-digit designation system to classify wrought aluminum alloys. This system provides a standardized method for identifying different types of aluminum based on their chemical composition. Each digit in the code represents specific information about the alloy. The first digit indicates the principal alloying element, while the second digit signifies modifications to the original alloy. The last two digits identify the specific alloy within the series. This system ensures consistency and clarity in the identification of aluminum alloys across various industries.

Importance in the US market

In the US market, the 4-digit designation system plays a crucial role. It helps manufacturers and engineers select the appropriate aluminum alloy for their applications. This system supports industries such as aerospace, automotive, and construction by providing reliable information about the material properties. The standardized labeling also facilitates international trade, as it aligns with global standards, ensuring that US-produced aluminum can compete in the global market.

Popular Aluminum Labels in the US

6061 Aluminum

6061 Aluminum is one of the most popular aluminum alloys in the United States. It belongs to the 6XXX series, characterized by its higher silicon content. This alloy is known for its excellent mechanical properties, including good corrosion resistance and high strength-to-weight ratio. 6061 Aluminum is heat-treatable, which enhances its strength and durability. It is widely used in structural applications, such as building frames and automotive components, due to its ease of welding and forming.

7075 Aluminum

Another prominent aluminum alloy in the US is 7075 Aluminum. This alloy falls under the 7XXX series, which contains more zinc and copper in its composition. 7075 Aluminum is renowned for its exceptional strength, making it ideal for high-stress applications. It offers nearly double the tensile strength and 1.5 times the shear strength of 6061 Aluminum. Despite being more challenging to weld and form, its superior strength makes it a preferred choice in aerospace and military industries, where performance is critical.

Aluminum Labeling System in the European Union

Overview of the EN AW- system

Explanation of the system

The European Union employs the EN AW- system to classify wrought aluminum alloys. This system uses a four-digit number, similar to the American system, but it includes the prefix "EN AW-" to indicate compliance with European standards. The first digit in the code identifies the primary alloying element, while the subsequent digits provide additional details about the alloy's composition. This classification method ensures that industries across Europe can easily identify and select the appropriate aluminum materials for their needs.

Importance in the EU market

In the European market, the EN AW- system holds significant importance. It provides a standardized framework that facilitates the selection of aluminum alloys for various applications. Industries such as automotive, construction, and aerospace rely on this system to ensure the quality and performance of their products. The EN AW- system also supports international trade by aligning with global standards, allowing European manufacturers to compete effectively in the global market.

Popular Aluminum Labels in the EU

6082 Aluminum

6082 Aluminum stands out as a popular choice within the European Union. This alloy belongs to the 6XXX series, known for its excellent mechanical properties and corrosion resistance. 6082 Aluminum offers a good balance of strength and workability, making it suitable for structural applications. Industries often use it in construction, transportation, and marine environments due to its durability and ease of machining.

Other notable labels

Apart from 6082 Aluminum, several other aluminum labels gain recognition in the EU. Alloys like 1050 Aluminum and 2024 Aluminum also find widespread use. 1050 Aluminum is known for its high purity and excellent corrosion resistance, making it ideal for chemical and food processing industries. 2024 Aluminum, on the other hand, offers high strength and fatigue resistance, making it a preferred choice in aerospace applications. These labels highlight the diversity of aluminum alloys available in the European market, catering to a wide range of industrial needs.

Aluminum Labeling System in China

Overview of the GB standard

Explanation of the system

China employs the GB standard to classify aluminum alloys. This system, specific to Chinese regulations, provides a structured approach to identifying aluminum materials. The GB standard assigns unique codes to different aluminum alloys, reflecting their chemical composition and mechanical properties. This classification ensures that industries can easily select the appropriate aluminum materials for their applications. The GB standard aligns with international practices, facilitating global trade and cooperation.

Importance in the Chinese market

The GB standard holds significant importance in the Chinese market. It supports various industries, including automotive, construction, and electronics, by providing reliable information about aluminum alloys. Manufacturers rely on this system to ensure the quality and performance of their products. The GB standard also enhances China's competitiveness in the global market by aligning with international standards, allowing Chinese-produced aluminum to meet global demands.

Popular Aluminum Labels in China

Unique GB standards

China's GB standard includes several unique aluminum labels that cater to specific industrial needs. These labels reflect the diverse applications of aluminum alloys in the Chinese market. Industries utilize these labels to identify materials that meet their specific requirements, ensuring optimal performance and durability. The GB standard's unique characteristics make it a valuable tool for manufacturers seeking high-quality aluminum materials.

ADC12 Aluminium Alloy

ADC12 Aluminium Alloy stands out as a prominent label within China's GB standard. This alloy, known for its excellent die-casting properties, is widely used in the automotive and industrial automation sectors. ADC12 offers superior filling characteristics, making it ideal for complex components like cylinder head covers and sensor brackets. Its versatility and reliability make it a preferred choice for manufacturers seeking high-performance aluminum materials.

Comparison of Aluminum Labeling Systems

Similarities between the systems

Common features

Aluminum labeling systems in the US, EU, and China share several common features. Each system provides a structured method for identifying aluminum alloys, ensuring consistency in material selection across industries. These systems classify alloys based on their chemical composition, which helps manufacturers choose the right materials for specific applications. For instance, the 4-digit designation in the US and the EN AW- system in the EU both use numbers to indicate the primary alloying elements. This similarity facilitates international trade, as manufacturers can easily understand and compare aluminum labels from different regions.

Shared applications

Despite regional differences, aluminum labels serve similar purposes across the globe. Industries such as aerospace, automotive, and construction rely on these labels to ensure the quality and performance of their products. For example, 6061 Aluminum and 7075 Aluminum are popular choices in the US for structural applications due to their strength and durability. Similarly, 6082 Aluminum in the EU and ADC12 Aluminium Alloy in China find widespread use in sectors requiring high-performance materials. These shared applications highlight the universal importance of aluminum labels in meeting industrial demands.

Differences between the systems

Unique characteristics

While similarities exist, each region's aluminum labeling system possesses unique characteristics. The US system, governed by the Aluminum Association, uses a straightforward 4-digit code. In contrast, the EU's EN AW- system includes a prefix to denote compliance with European standards. China's GB standard, specific to Chinese regulations, assigns unique codes that reflect local industrial needs. These differences underscore the regional preferences and regulatory environments that influence aluminum labeling practices.

Regional preferences

Regional preferences play a significant role in the choice of aluminum labels. In the US, 6061 Aluminum is favored for its excellent mechanical properties, while 7075 Aluminum is preferred for high-stress applications. The EU market leans towards 6082 Aluminum for its balance of strength and workability. In China, ADC12 Aluminium Alloy dominates due to its superior die-casting properties, making it ideal for automotive and industrial automation sectors. These preferences reflect the diverse industrial landscapes and specific requirements of each region.

Implications for Industries

Impact on Manufacturing

Material Selection

Industries rely heavily on aluminum labels to guide material selection. Each label, such as 6061 Aluminum or ADC12 Aluminium Alloy, indicates specific properties that suit different applications. For instance, 6061 Aluminum offers excellent mechanical properties, making it ideal for structural applications in construction and aerospace. On the other hand, ADC12 Aluminium Alloy is favored for its superior die-casting properties, particularly in the automotive sector. These labels help manufacturers choose the right materials, ensuring optimal performance and durability in their products.

Cost Considerations

Cost plays a crucial role in manufacturing decisions. Aluminum labels provide valuable information about the cost-effectiveness of different alloys. For example, 7075 Aluminum offers exceptional strength but may come at a higher cost due to its complex composition. Manufacturers must weigh the benefits of using high-strength alloys against their budget constraints. By understanding the properties and costs associated with each aluminum label, industries can make informed decisions that balance performance and affordability.

Future Trends

Innovations in Labeling

The future of aluminum labeling promises exciting innovations. Researchers are exploring new ways to enhance the labeling process, making it more efficient and accurate. Advances in technology may lead to the development of smart labels that provide real-time data on material properties. These innovations could revolutionize how industries select and use aluminum alloys, offering greater precision and flexibility in manufacturing processes.

Global Market Influence

Aluminum labels significantly impact the global market. As industries continue to expand internationally, the demand for standardized labeling systems grows. The alignment of labeling systems, such as the US's 4-digit designation and the EU's EN AW- system, facilitates international trade and cooperation. This global influence ensures that manufacturers can access high-quality aluminum materials from around the world, meeting the diverse needs of various industries.

How we do it

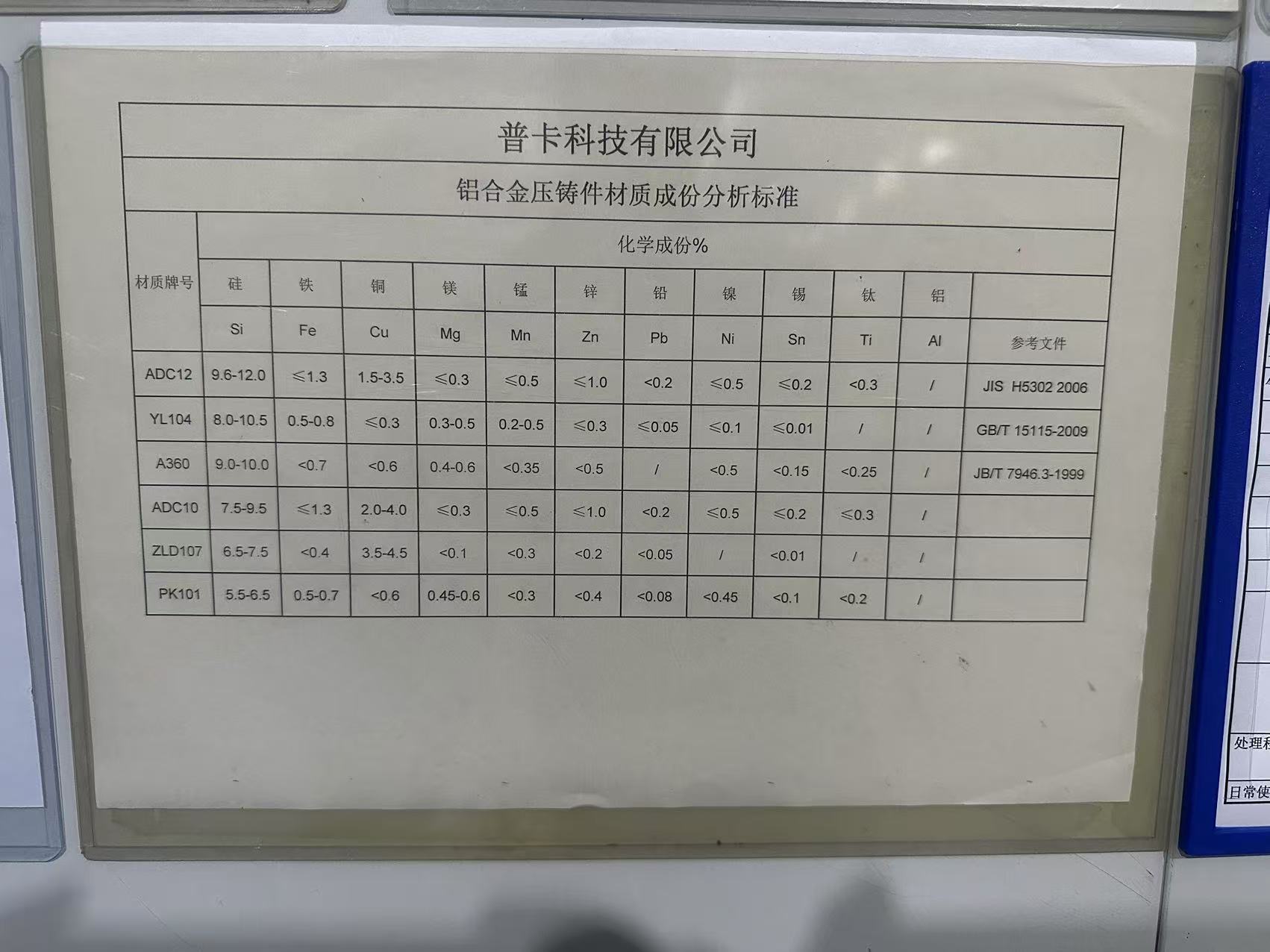

At Hunan Puka, one of our commonly used material is ADC12 and it is widely applied in automobile, machinery & equipment industries. Other materials are YL104, A360, ADC10, ZLD107 and other customised types. Complying with JIS (Japanese Industrial Standards) and GB/T(Chinese National Standards), the chemical compositions are examined in our quality process.

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 800 tons. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.