Aluminium vs Magnesium Die Casting Materials for Lightweight Engineering

Key Differences Between Aluminium and Magnesium Die Casting

Compare aluminium and magnesium die casting for lightweight engineering.

Features | aluminium die casting parts | magnesium die casting parts |

|---|---|---|

Weight | Heavier, density about 2.7 g/cm³ | Lighter, density about 1.8 g/cm³ |

Strength | Higher tensile strength and durability | Lower strength but higher specific strength |

Excellent, forms protective oxide layer | Moderate, needs coatings to resist corrosion | |

Thermal Conductivity | Around 96 W/m-K, good heat dissipation | Up to 156 W/m-K, faster heat transfer |

Cost | Lower and more stable pricing | Higher cost, special handling required |

Recyclability | Highly recyclable with energy savings | Recyclable but less common globally |

Good for complex shapes, longer die life | Faster cycle, thinner walls possible | |

Safety | Safer to handle during manufacturing | Fire risk, requires special precautions |

Engineers often choose between aluminium magnesium parts for lightweight projects. Magnesium is the lightest structural metal, with a density of about 1.8 g/cm³, while aluminium alloys have a density near 2.7 g/cm³. This means magnesium is approximately 35% lighter than aluminium. However, aluminium costs less and offers excellent rust resistance. The table below highlights these differences:

Material | Density (kg/dm³) |

|---|---|

Magnesium | ~1.74 |

Aluminum | ~2.75 |

Both aluminium magnesium parts have unique advantages, and the best choice depends on the specific requirements of the project.

Properties

Weight

Magnesium is the lightest metal used in die casting. Its density is about 1.8 g/cm³. Aluminium has a density close to 2.7 g/cm³. Magnesium is about 30% lighter than aluminium. Engineers pick magnesium when they want to make things as light as possible. For example, car seat frames and brackets made from magnesium can weigh up to 31% less than those made from aluminium. This helps designers build lighter cars and products. Lighter vehicles can use less fuel and are easier to handle.

Density (g/cm³) | Weight Reduction Compared to Aluminum | |

|---|---|---|

Magnesium | 1.8 | ~33% lighter |

Aluminum | 2.7 | N/A |

Tip: Magnesium die casting is great for projects where every gram matters, like in cars and airplanes.

Strength

Aluminium and magnesium both have good strength for light parts. Their properties are not the same. Some aluminium alloys, like AlZn5Mg4Cu, can be very strong after heat treatment. Magnesium alloys, such as AZ91, are not as strong as aluminium but have high specific strength because they are lighter. Both materials can get cracks at casting pores. Magnesium alloys can take in more energy when bent or crushed. This makes them useful for parts that need to handle impacts.

Magnesium Alloys (e.g., AZ31) | ||

|---|---|---|

Tensile Strength | Slightly below mild steel | Lower than aluminium 6061-T6 |

Specific Strength | High | Highest among tested alloys |

Energy Absorption | Up to 50% less than Mg alloys | Up to 50% more than Al, >10x more than steel |

Magnesium’s high specific strength and energy absorption make it a good pick for light, impact-resistant parts. Aluminium is better for parts that need more strength.

Corrosion Resistance

Aluminium die casting parts resist corrosion better than magnesium parts. Aluminium forms a strong oxide layer that protects it from rust. Magnesium alloys, like AZ91, use the β phase (Mg17Al12) to slow down corrosion. But magnesium is still more active and less resistant than aluminium. Magnesium’s corrosion rate can change over time, especially as it ages. Aluminium’s protective layer stays more stable.

Aluminium alloys have a steady protective layer and resist pitting.

Magnesium alloys’ resistance depends on the β phase’s size and spread.

Magnesium is more likely to corrode, especially in tough or salty places.

Note: Aluminium die casting is best for parts that will get wet or face harsh conditions.

Thermal Conductivity

Both aluminium and magnesium move heat well, but not the same way. Magnesium alloys like AZ91 have a thermal conductivity of about 51 W/m-K. Aluminium alloys can reach around 96 W/m-K. Some sources say magnesium’s thermal conductivity can be as high as 156 W/m-K. Still, aluminium usually works better for most die casting jobs.

Material | Thermal Conductivity (W/m·K) | Impact on Die Casting Process |

|---|---|---|

Magnesium | ≈156 | Moves heat fast, needs careful mold temperature control |

Aluminum | ≈96 | Cools slower, may wear out molds faster |

Aluminium’s higher thermal conductivity helps it get rid of heat. This makes it a good choice for electronic cases and heat sinks.

Cost

Cost is important when picking a material. Aluminium die casting usually costs less than magnesium. Aluminium is easy to find, can be recycled, and is flexible in design. This keeps its price steady. Magnesium can cost more because it needs special handling and its price changes more. But magnesium can save money by needing fewer parts in complex designs.

Aluminium Die Casting | Magnesium Die Casting | |

|---|---|---|

Material Cost | Lower, steady market | Higher, more changeable |

Production Efficiency | High, recyclable | High, fewer joints, thin-walled parts |

Tooling Costs | High, but recycling helps | High, but fewer parts needed |

Market Demand | Strong, steady growth |

Aluminium is cheaper for most projects. Magnesium can lower costs in tricky designs.

Recyclability

Aluminium is the best for recycling. It can be recycled over and over without losing quality. In the US, about 35% of aluminium is recycled. In Europe, over 76% gets recycled. Recycling aluminium saves up to 95% of the energy needed to make new metal. Magnesium is also recyclable and good for the environment. But aluminium’s recycling system is bigger and more developed.

Aluminium | |

|---|---|

Recycled Content in Products | 73% (cans) |

Recycling Rate (Europe) | 76.1% |

Energy Savings from Recycling | 95% less energy than new metal |

Recyclability | Infinite, no quality loss |

Environmental Impact | Lower greenhouse gas emissions |

Tip: Aluminium die casting is the best choice for projects that care about the environment.

Manufacturability

Both aluminium and magnesium die casting can make complex shapes and fine details. Magnesium alloys, like AZ91D and AM60B, are very precise and stable. They are easy to machine and have a smooth finish. This can cut down on extra work. Magnesium’s low density helps make light, detailed parts. Aluminium die casting also makes complex shapes and has good surface finishes. It is strong for its weight. Both are used in cars, planes, and electronics.

Magnesium die casting makes thin, accurate parts.

Aluminium die casting resists corrosion better and is easier to find.

Both can be used for large production runs and automation.

Magnesium and aluminium are both good for making things. The best choice depends on what balance of weight, strength, and corrosion resistance you need.

Aluminium Magnesium Parts

Comparison Table

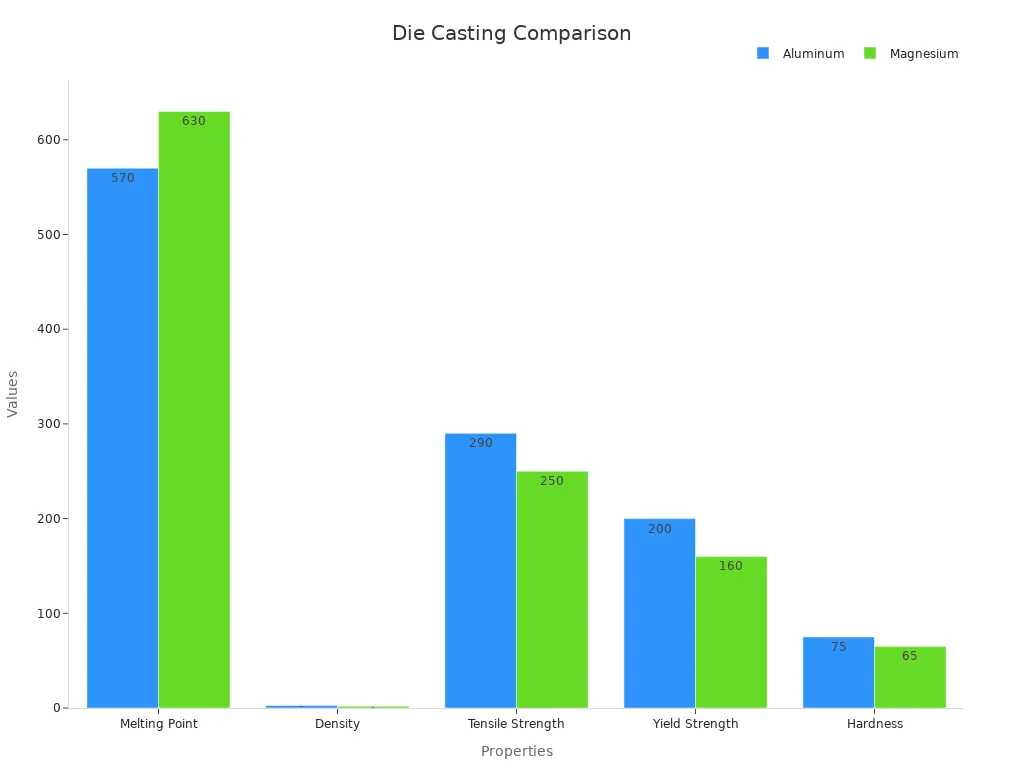

Engineers sometimes need to compare aluminium magnesium parts quickly. The table below shows their main properties next to each other. This helps designers pick the best material for their project.

Property | Aluminum Die Casting (A380) | Magnesium Die Casting (AZ91D) |

|---|---|---|

Melting Point (°C) | ~570 | ~630 |

Density (g/cm³) | ~2.7 | ~1.8 |

Tensile Strength (MPa) | ~290 | ~250 |

Yield Strength (MPa) | ~200 | ~160 |

Hardness (HB) | ~75 | ~65 |

Corrosion Resistance | Good | Moderate |

Wall Thickness | Thicker minimum | Can achieve thinner walls |

Cycle Time | Longer | Shorter |

Cost | Lower | Higher |

Typical Applications | Engine blocks, housings, brackets | Automotive parts, electronics |

Tip: Magnesium parts are lighter and can have thinner walls. Aluminum parts are stronger and resist rust better.

Key Differences

Aluminium magnesium parts both have special benefits for lightweight engineering. Knowing these differences helps engineers pick what works best.

Weight: Magnesium is about 33% lighter than aluminum. This makes magnesium great for things like planes or electric cars.

Strength: Aluminum die casting parts are stronger. They are good for parts that need to hold more weight.

Corrosion Resistance: Aluminum makes a strong layer that stops rust. Magnesium needs extra coatings or special alloys to avoid rust, especially in wet places.

Thermal Conductivity: Magnesium moves heat faster than aluminum. This helps in electronics where heat needs to go away quickly.

Manufacturing: Magnesium can make thinner parts and is faster to cast. This can make production quicker and parts lighter. Aluminum uses regular tools and is easier to find.

Cost: Aluminum die casting usually costs less. Magnesium can cost more at first, but its tools last longer in big jobs.

Recyclability: Both can be recycled, but aluminum recycling is more common around the world.

Engineers pick aluminium magnesium parts based on what the project needs. Magnesium is best for light designs. Aluminum is better when you need strength and rust protection.

When to Choose Each Material

Choose magnesium when making parts that must be very light, like car seats, laptop frames, or drone bodies.

Choose aluminum for parts that get wet, need to be strong, or must be cheap, like engine housings or outdoor gear.

Researchers found that cooling speed during casting changes both materials. Faster cooling makes smaller grains and stronger parts. Both magnesium and aluminum get stronger this way, but magnesium’s lightness helps in super-light designs.

Aluminium magnesium parts give engineers many choices. The best material depends on weight, strength, cost, and where the part will be used.

Applications

Automotive

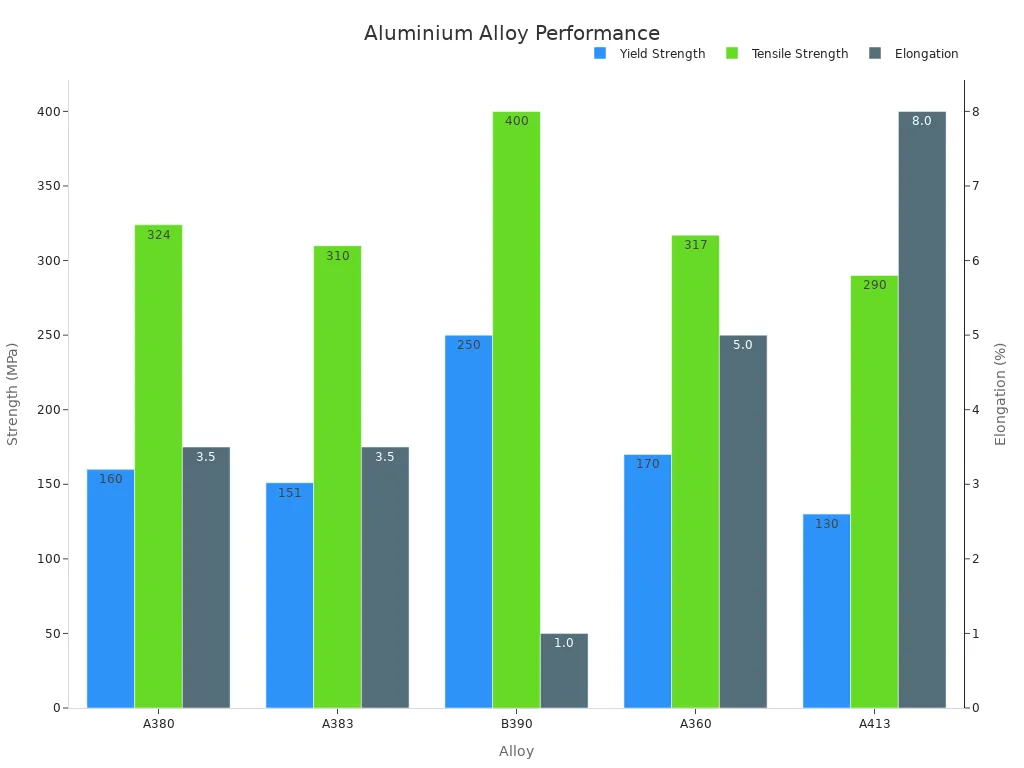

Car makers use aluminium and magnesium die casting parts. These parts help make cars lighter and better on gas. Aluminium alloys like A380 and A383 are strong and do not rust easily. They are good for engine blocks, transmission housings, and brackets. Magnesium parts are about 33% lighter than aluminium parts. This helps cars weigh less and use less fuel. Magnesium can also make thinner parts and is faster to cast. That is why it is used for seat frames, steering wheels, and dashboards. Car companies like aluminium because it is cheaper. They like magnesium because it makes light and tricky shapes.

Alloy | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Key Use |

|---|---|---|---|---|

A380 | 160 | 324 | 3.5 | Engine blocks, housings |

AZ91D | 160 | 250 | 3.0 | Seat frames, brackets |

Aluminium and magnesium help car makers meet tough rules for fuel and pollution.

Aerospace

Planes and rockets need parts that are light and strong. Both aluminium and magnesium die casting parts are used in these vehicles. Aluminium does not rust and keeps its shape well. It is used for the outside of planes and engine covers. Magnesium is even lighter and handles shaking better. This makes it good for inside parts, gearboxes, and satellite cases. The aerospace industry follows strict rules to keep things safe and high quality.

Big planes use aluminium for main parts and magnesium for inside pieces.

Military and space vehicles use magnesium for fast casting and aluminium for strength.

Electronics

Electronics makers pick aluminium or magnesium based on what the device needs. Magnesium alloys like AM60 are strong and soak up shocks well. They also let heat out fast. Magnesium cases are lighter and can be made thinner than aluminium or plastic ones. This helps make laptops, phones, and cameras lighter. Magnesium also blocks unwanted signals, which protects electronics. Aluminium is still used a lot because it does not rust and costs less. It is common in heat sinks and covers.

Magnesium die casting parts often take the place of plastic in electronics. This makes devices up to 36% lighter and helps them stay cool.

Other Uses

Aluminium and magnesium die casting parts are used in many other things. In sports, magnesium makes bikes and rackets lighter and easier to use. Aluminium is strong and does not rust, so it is good for outdoor and boat gear. Both materials are found in power tools, medical machines, and robots. More people want lighter and stronger products, so the die casting market is growing.

Magnesium helps make thin, tricky shapes for new designs.

Aluminium is trusted and easy to recycle for making lots of parts.

Both materials help engineers create new things. They make it easier to solve problems in lightweight engineering.

Manufacturing

Process Differences

Aluminium and magnesium die casting use almost the same machines. The steps are a bit different. Magnesium melts at a lower temperature, about 650°C. Aluminium needs a higher melting temperature. Magnesium dies get very hot, often at least 700°C. Aluminium dies work at 150°C to 350°C. Magnesium dies can wear out faster. This is because of chemical reactions. They need special coatings and more care. Both metals use H13 steel for dies. Magnesium sometimes needs extra protection.

Parameter / Process Aspect | Magnesium Die Casting | Aluminum Die Casting |

|---|---|---|

Melting Point | ~650°C | Higher than magnesium |

Die Temperature | Minimum 700°C | 150–350°C |

Cycle Time | 20–40 seconds | 20 seconds–1.5 minutes |

Die Material | H13 steel, 4140 steel | H13 steel |

Die Wear and Maintenance | Faster wear, needs coatings | Longer die life |

Surface Finishing | Needs coatings for corrosion resistance | Anodizing, powder coating |

Magnesium die casting makes thinner, lighter parts. Aluminium parts last longer and resist rust better.

Cycle Time

Cycle time means how fast each part is made. Magnesium cools and hardens faster than aluminium. Its cycle times are 20 to 40 seconds in high-pressure die casting. Aluminium can be as quick as 20 seconds. Sometimes it takes up to 1.5 minutes, depending on the part. Magnesium’s speed helps make lots of parts fast. For medium batches, both metals use low-pressure or vacuum die casting. These take 2 to 8 minutes per part. Aluminium can go faster with special die inserts and cooling tricks. This helps remove heat and saves money.

High-pressure magnesium die casting: 20–60 seconds per part

High-pressure aluminium die casting: 20 seconds–1.5 minutes per part

Low-pressure and vacuum processes: 2–8 minutes per part

Magnesium’s fast cycle time helps make more parts quickly. Aluminium can also be fast with the right tools.

Safety

Safety is very important for both metals. Magnesium is more risky because it can catch fire if not handled right. Factories use sealed ovens and special gases like argon to stop fires. Workers do not use water-based coolants with magnesium. Water can react badly with hot magnesium. Aluminium also needs safety steps. Workers wear heat-proof gear and use good air flow to stay safe from fumes and hot metal. Both metals need strong safety rules and equipment to stop accidents.

Both aluminium and magnesium die casting need careful safety steps. Magnesium needs extra care to stop fires.

Choosing Material

Project Needs

Picking between aluminum and magnesium die casting starts with knowing what the project needs. Engineers think about many things before they decide. Every project needs a special mix of weight, strength, price, and how long it will last.

Weight Sensitivity: Magnesium is best when every bit of weight matters, like in planes or small gadgets.

Strength and Stability: Aluminum is stronger and works well for parts that must hold up under pressure.

Corrosion Resistance: Aluminum does not rust easily, so it is good for things used outside.

Cost Constraints: Aluminum usually costs less and its price does not change much, which helps with planning.

Wall Thickness: Magnesium can make thinner walls, which helps make lighter and smaller parts.

Environmental Impact: Both can be recycled, but aluminum recycling is more common.

Application Environment: Aluminum is better for parts that get wet or touch chemicals. Magnesium is good for inside parts, especially if it has a special finish.

Engineers use planning tools like DFMEA and process checks to make sure the material fits the project. They also check parts during and after making them to be sure everything is right.

Decision Tips

A step-by-step plan helps engineers pick the best material. The table below shows the main things to think about:

Criteria | Aluminum Die Casting | Magnesium Die Casting |

|---|---|---|

Weight | Heavier | Lighter |

Strength | Higher | Moderate |

Corrosion Resistance | Excellent | Moderate (needs coating) |

Cost | Lower | Higher |

Wall Thickness | Standard | Thinner possible |

Recyclability | Excellent | Good |

Application Suitability | Outdoor, structural | Interior, lightweight |

Pick aluminum for parts that need to be strong, not rust, or cost less.

Use magnesium for parts that must be light, thin, or have tricky shapes where weight is very important.

Ask experts and use special tools to help balance cost, quality, time, and the environment for the best choice.

A checklist with project goals, where the part will be used, what it must do, and how much it can cost will help you choose the right material. Computer tests and advice from suppliers can help make the best choice.

Aluminium magnesium parts both have special uses in lightweight engineering. Aluminium die casting makes parts that are strong and resist rust. These parts are also made with high accuracy. Magnesium die casting is the lightest metal used for structure. It is easy to shape and helps stop shaking.

Aluminium is good when you want to save money and stop rust. It is also great for many different designs.

Magnesium is best when making things that must be very light, like in planes or electronics.

Engineers need to pick the right material for each project. Talking to experts helps make sure the part works well and fits the budget.

FAQ

What is the main difference between aluminium and magnesium die casting parts?

Aluminium die casting parts are heavier. They do not rust as easily. Magnesium die casting parts are much lighter. They can be made into thinner shapes. Engineers pick one based on if they need more strength, less weight, or better rust protection.

Which material is better for outdoor use?

Aluminium is better for things used outside. It makes a strong layer that stops rust. Magnesium needs extra coatings to last outdoors. Aluminium parts last longer in wet or rough weather.

Are magnesium die casting parts always more expensive than aluminium?

Magnesium parts usually cost more to make. This is because they need special care and the material costs more. Aluminium is easier to find and recycle. That is why it usually costs less for most jobs.

Can both aluminium and magnesium die casting parts be recycled?

Yes, both can be recycled. Aluminium is recycled more often around the world. Recycling aluminium saves more energy. Many companies use recycled aluminium. Magnesium recycling is growing but not as common yet.

Which material is safer to use in manufacturing?

Aluminium is safer to use when making parts. Magnesium can catch fire if not handled right. Factories use special safety steps for magnesium. Both need good safety rules, but magnesium needs extra care.

See Also

Magnesium Alloys Transforming The Future Of Lightweight Production

Understanding The Mechanics Behind Aluminum Extrusion And Casting

Comparing Cost Benefits Of Plastic And Aluminum Prototypes

Essential Trends Shaping The 2025 Automotive Aluminum Casting Industry

Guidelines For Selecting Optimal Die Casting Closing Force Effectively

About Hunan Puka

Established in 2016 and based in Hunan, China, with a liaison point in Berlin, we are a Tier 2 supplier for the automobile industry. We specialize in the production of customized aluminum die-casting parts designed for machines with a closing force ranging from 280 to 1250 tons, with subsequent manufacturing process CNC machining and surface treatment. Our commitment to quality is reflected in our accredited quality management system, certified by ISO9001:2015 and IATF16949:2016 standards.